POLYURETHANE

MACHINERY

CORPORATION

PH-2 SERVICE MANUAL

12. TROUBLESHOOTING

12 TROUBLESHOOTING

This PH Series Proportioner has been designed and built to withstand severe working con-

ditions with a high degree of reliability, provided that it is used in a suitable application

by a properly trained operator. This chapter contains information on possible faults that

may interrupt the operation of the PH Series Proportioner. The information provided will

serve as a guideline to detect and resolve problems. In any case, feel free to contact your

authorized PMC distributor, where a qualified technician will advise you.

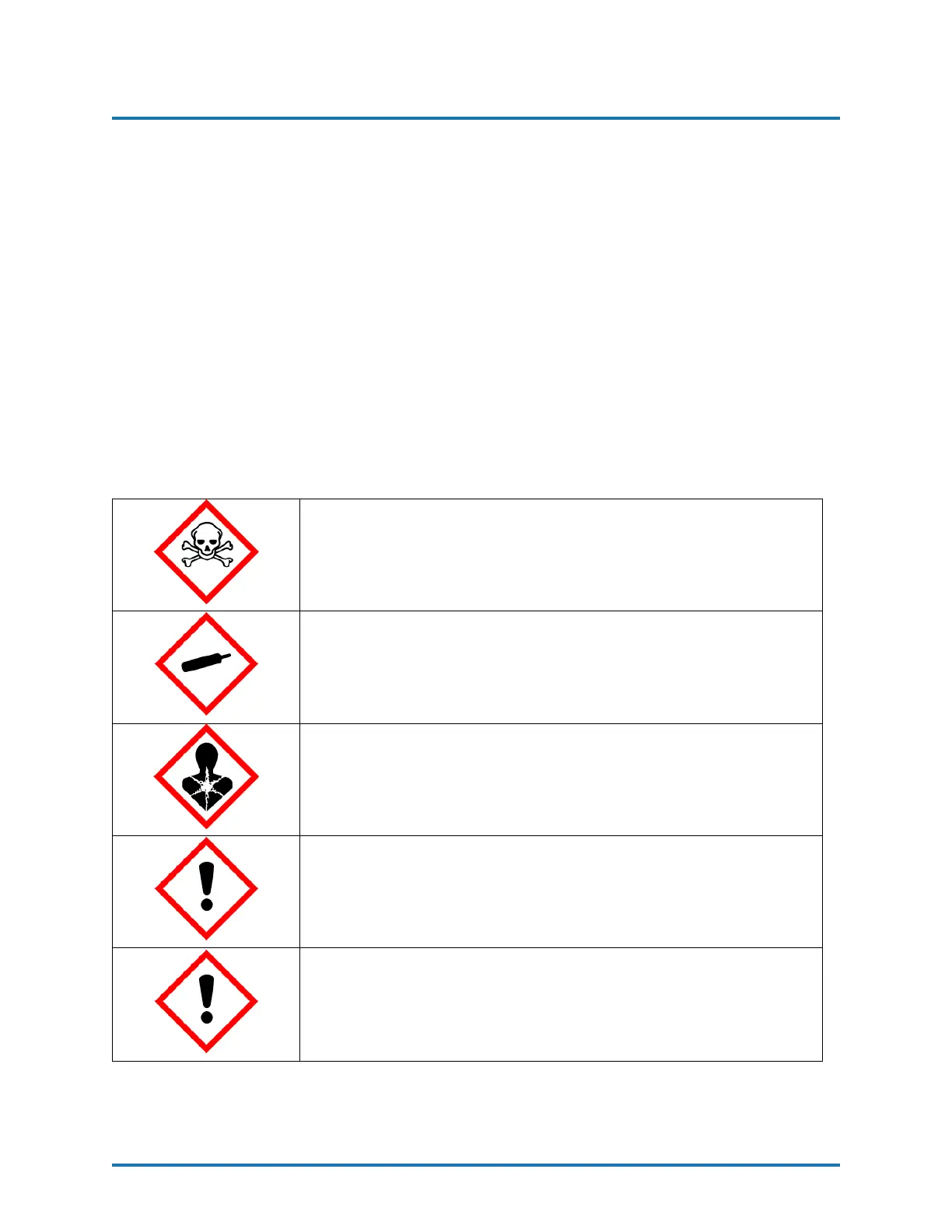

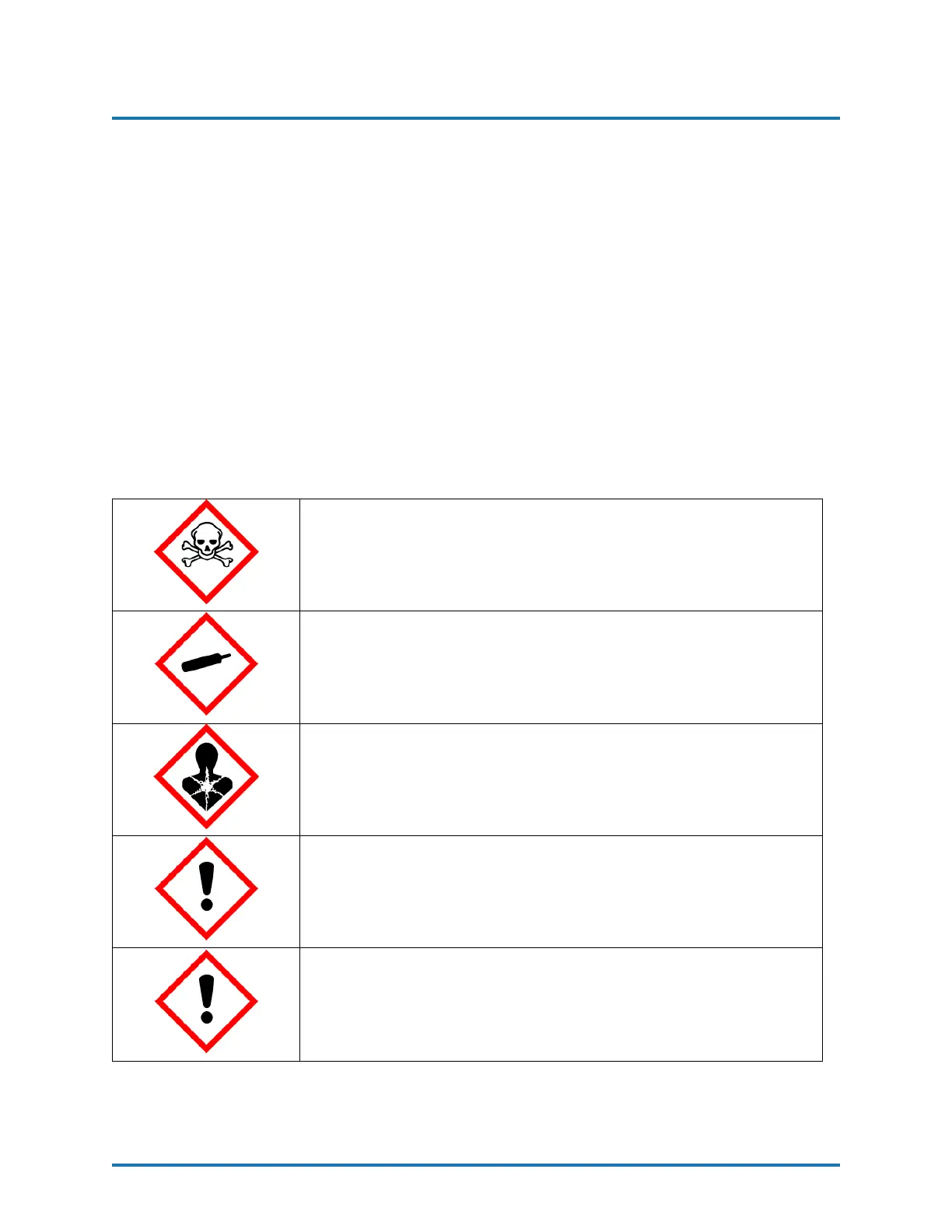

WARNING! Only qualified personnel should perform troubleshoot-

ing; unqualified personnel may cause damage to the unit and put

the operator at risk.

To prevent possible injury caused by incorrect handling of the

raw materials and solvents used in the process, carefully read the

Material Safety Data Sheet (MSDS) provided by your supplier.

Deal with the waste caused according to current regulations.

To avoid damage caused by the impact of pressurized fluids, do

not open any connection or perform maintenance work on com-

ponents subject to pressure until the pressure has been completely

eliminated.

Use suitable protection when operating, maintaining or being

present in the area where the equipment is functioning. This in-

cludes, but is not limited to, the use of protective goggles, gloves,

shoes and safety clothing and breathing equipment.

The equipment includes components that reach high temperatures

and can cause burns. Hot parts of the equipment must not be

handled or touched until they have cooled completely.

To prevent serious injury through crushing or amputation, do

not work with the equipment without the safety guards installed

on the moving parts. Make sure that all the safety guards are

correctly reinstalled at the end of the repair or maintenance work

of the equipment.

REVISION 1.2 32

Loading...

Loading...