POLYURETHANE

MACHINERY

CORPORATION

PH-2 SERVICE MANUAL

12. TROUBLESHOOTING

3. Safety Pressure Switch - Each Metering Pump has a Safety Pressure Switch set to

2,200 psi. for # 123 pumps, 3,200 psi for #61 pumps. When the material system

reaches this pressure, the Safety Pressure Switch will remove power from the

Directional Valve and Direction Indicator Lights (Q, section 5). Lack of Direction

Indicator Lights along with high pressure indicated on one or both of the material

Pressure Gauges (E, F, section 5) is an indication of an over-pressure condition.

The Safety Pressure Switches are a momentary design; when the pressure bleeds

off the Metering Pump Line will resume normal operation. However, the cause of

the over-pressure should be determined and corrected. The most common causes

are:

a. Cavitations of the Metering Pump on the low pressure side causing high

pressure on the opposite side.

b. A restriction in the Spray Gun on the high pressure side.

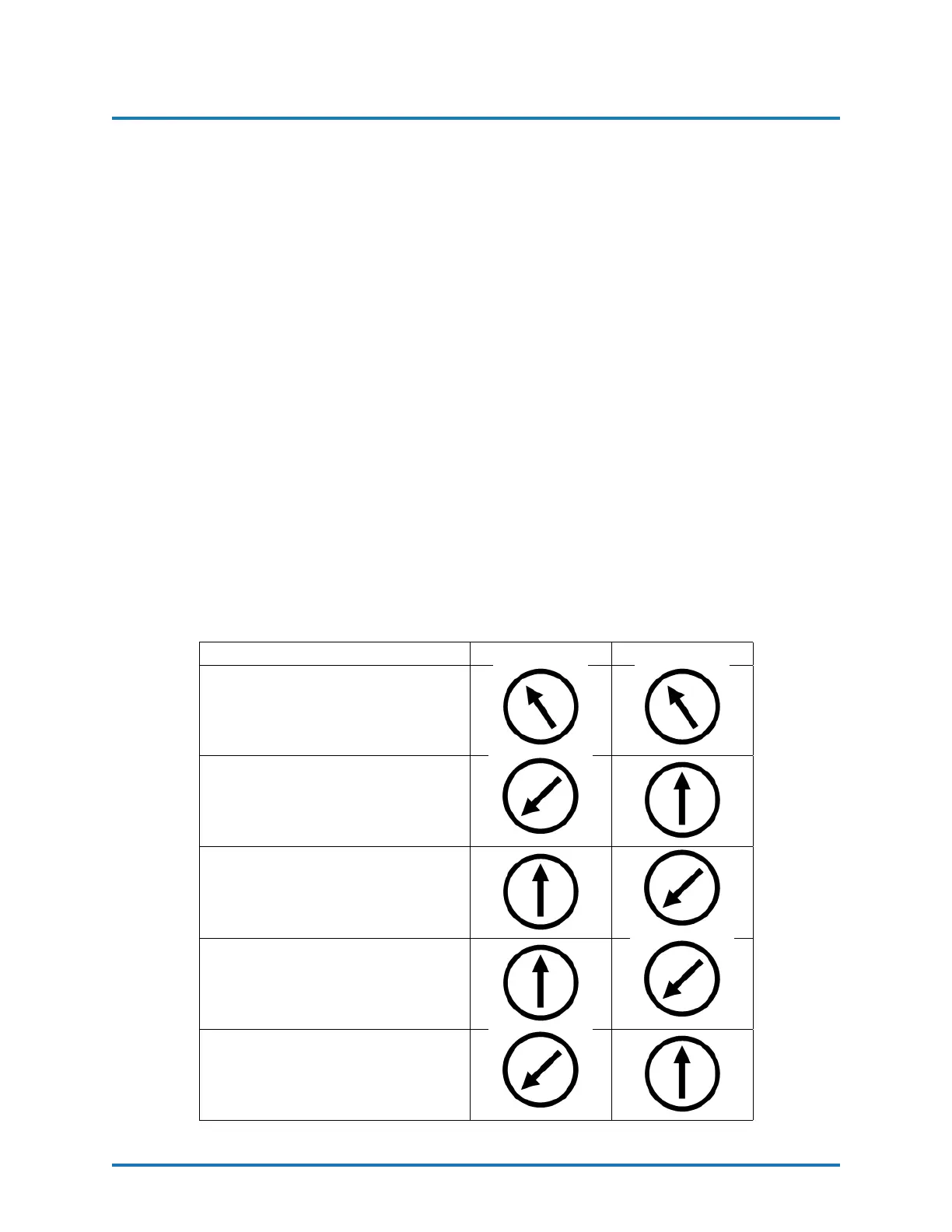

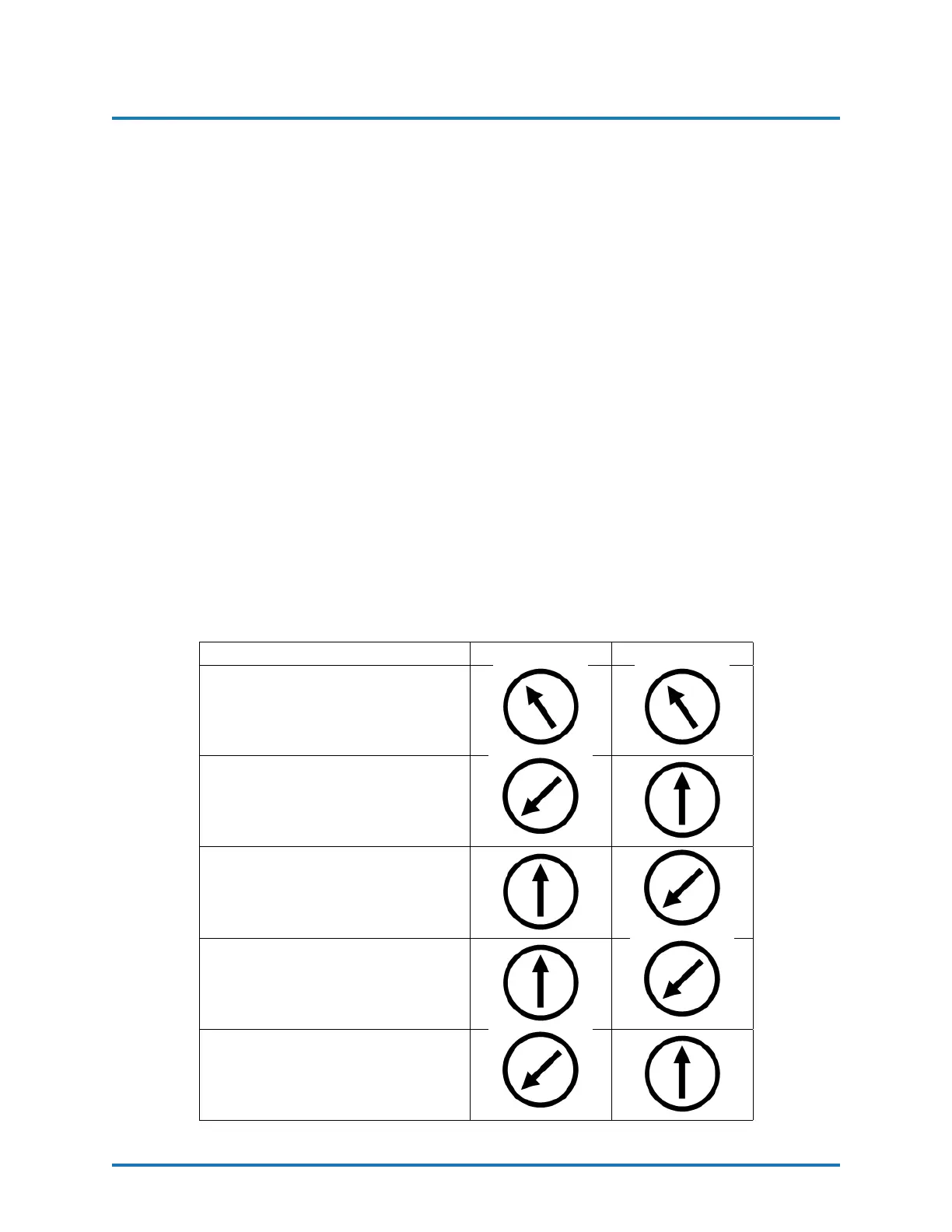

4. Pressure/Material Imbalance - Troubleshooting this problem requires the appli-

cator to:

a. Know what the NORMAL spray pressures are for the application in progress.

b. Determine what material is NOT exiting the Mixing Chamber.

c. Read the Pressure Gauge on the problem side and interpret the reading.

Material Condition ”A” GAUGE ”R” GAUGE

NORMAL

LACK OF ISO (A)

LACK OF POLY (R)

RESTRICTION OF ISO (A)

RESTRICTION OF POLY (R)

REVISION 1.2 40

Loading...

Loading...