ENGINE

3.11

OIL PRESSURE TEST -

EH50PL

1. Remove blind plug on front left cylinder head.

2. Insert a 1/8 NPT oil pressure gauge adaptor into

the cylinder head and attach the gauge.

3. Start engine and allow it to reach operating

temperature, monitoring gauge indicator.

NOTE: Use Polaris Premium 4 Synthetic Engine

Lubricant (PN 2871281).

Oil Pressure at 5500 RPM (Engine Hot):

Standard: 20 PSI

Minimum: 12 PSI

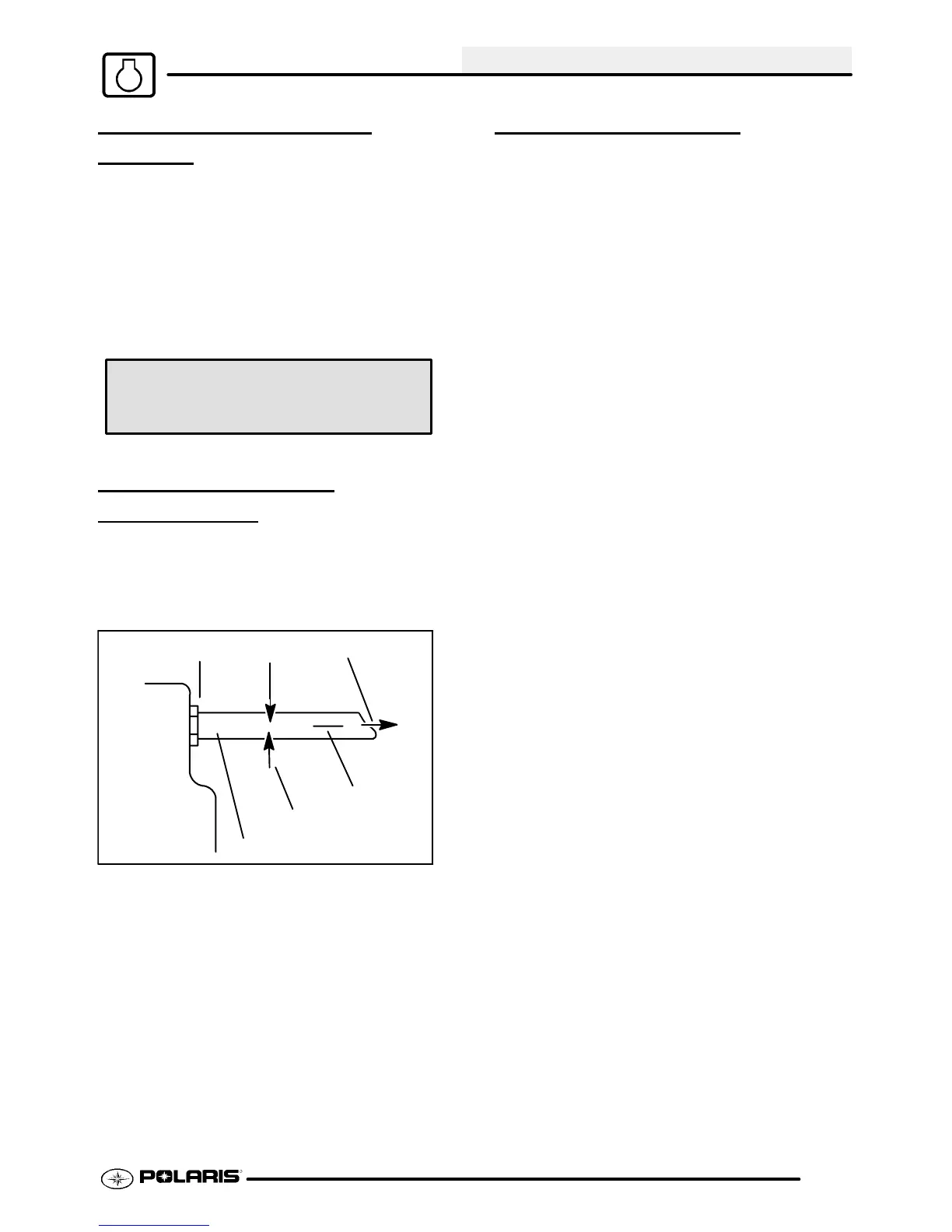

OIL PUMP PRIMING

PROCEDURE

NOTE: This priming procedure must be

performed whenever the oil hose connection

between the oil tank and pump inlet has been

disconnected.

Slit

Oil Tank

ent Hose

To Air Box

Pinch Off

2I

Approx.

1. Clamp or pinch off vent line approximately 2I

fromoiltanktoavoidtheendofoiltankventfitting,

and the vent line’s pressure relief slit

2. Run engine for 10--20 seconds.

3. Shut engine off. Remove the vent line clamp. A

rushofairshouldbeheard,indicatingtheoilpump

is properly primed and ready for field operation.

Note: Ifthesystem is primedproperlyyoushould

hear some air release. If you do not, the system

has not primed. Repeat theprocess if necessary.

OIL FLOW -- EH 50PL

The chart on Page 3.12 describes the flow of oil

throughtheEH50PLengine. Beginningattheoiltank,

the oil flows through a screen fitting in the bottom of

the tank and into the oil supply hose. The feed side

oftheoilpumpdrawsoilthroughthehoseand intothe

crankcase oil gallery, and then pumps the oil through

another passage to the one way valve. (When the

engine is off, the one way valve closes to prevent oil

in the tank from draining into the crankcase.) The oil

ispumpedthroughadeliverypipe totheoilfilter. Ifthe

oil filteris obstructed, a bypass valvecontained in the

filter allows oil to bypass the filter element.

At this point, the oil is diverted in two directions. Oil

is supplied to the camshaft through the left front

cylinder stud, and an oil passage in the head. Oil

entersthecamshaftthroughthePTO (L)journal. The

camshaft journals, cam lobes, and rocker arms are

lubricated through holes in the camshaft. The oil

lubricates the cam chain and sprocket and drains to

the sump.

The other oil path from the filter leads through a

delivery pipe to the crankcase main oil gallery, which

leads to the stator plate oil passage. Here it passes

through the slotted friction bearing (located in the

stator plate) into the crankshaft. An oil seal on the

stator plate prevents oil from entering the

stator/flywheel area. Oil travels through the

crankshaft tothecrank pin, lubricatingtheconnecting

rodlargeendbearingdirectly. Oilalsopassesthrough

an oil jet (drilled orifice) in the end of the crank pin to

the PT O end main bearings and counterbalancer

gears.

Residual oil from thelubrication of the crankshaft and

connecting rod indirectly lubricates the cylinder wall,

piston,rings,connectingrodsmallendbearing,piston

pin, oil/water pump drive gears, cam chain and drive

sprocket, and Magneto end crankshaft main bearing.

The one-way valve is located on the front left (PT O)

side of the crankcase. The valve prevents oil in the

tank from draining into the engine sump when the

engine is off. The valve mechanism consists of a

plunger, return spring, guide plug, and sealing

washer . When theengine is running, oil pressure lifts

the plunger off the seat, allowing oil flow. When the

engine is off, spring pressure forces the plunger

against the oil passage seat, preventing oil flow from

the tank to the sump. The one-way valve requires

very little maintenance. If engine oil drains into the

sumpwhentheengineisoff,inspectthe valvesealing

surface for debris or damage. Inspect the return

spring for distortion or damage.

Loading...

Loading...