CLUTCHING

6.2

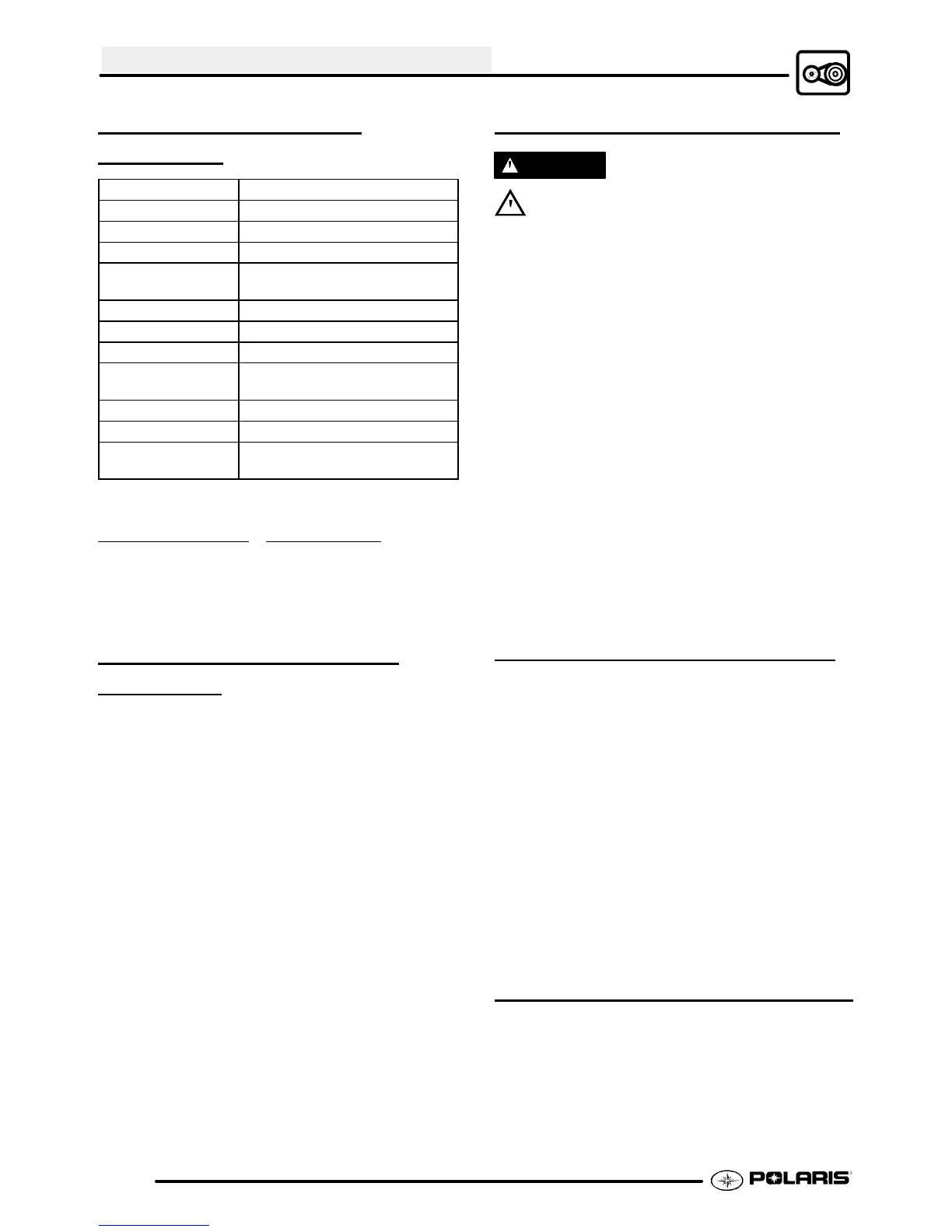

SPECIAL TOOLS AND

SUPPLIES

PART NUMBER TOOL DESCRIPTION

2870506 Clutch Puller

9314177 Clutch Holding Wrench

2871358 Clutch Holding Fixture

2870341 Drive Clutch Spider Removal and

Install Tool

2870654 Clutch Offset Alignment Tool

2870913 Driven Clutch Puller

2870910 Roller Pin Tool

2871226 Clutch Bushing Replacement

Tool Kit

2870386 Piston Pin Puller

8700220 Clutch Compression Tool

2871025 Clutch Bushing Replacement

Tool Kit

SPECIAL SUPPLIES PART NUMBER

Loctitet 680 2870584................

RTV Silicone Sealer 2870661.........

Loctitet Gasket Remover 2870601....

PVT SYSTEM FASTENER

T

ORQUES

Drive Clutch Retaining Bolt 40 ft. lbs. (54 Nm)...

Driven Clutch Retaining Bolt 17 ft. lbs. (23 Nm)..

PVT Inner Cover Bolts 12 ft. lbs. (16 Nm).......

Drive Clutch Spider (Standard Clutch) 200 ft. lbs..

(271 Nm)

Drive Clutch Cover Plate 90 in. lbs. (10 Nm).....

PVT OPERATION OVERVIEW

W ARNING

All PVT maintenance or repairs should be

performed only by a certified Polaris Master Service

Dealer(MSD)technicianwhohasreceivedtheproper

training and understands the procedures outlined in

this manual. Because of the critical nature and

precision balance incorporated into the PVT

components, it is absolutely essential that no

disassembly or repair be made without factory

authorized special tools and service procedures.

The Polaris Variable Transmission (PVT) consists of

three major assemblies: 1) The Drive Clutch; 2) The

Driven Clutch; and 3) The Drive Belt. The internal

components of the drive clutch and driven clutch

controlengagement (initialvehiclemovement), clutch

upshift and backshift. During the development of a

Polaris ATV, the PVT system is matched first to the

enginepowercurve;then toaverageridingconditions

and the vehicle’s intended usage. Therefore,

modifications or variations of components at random

are never recommended. Proper clutch setup an d

careful inspection of existing components must be the

primary objective when troubleshooting and tuning.

DRIVE CLUTCH OPERATION

Drive clutches primarily sense engine RPM. Thetwo

major components which control its shifting function

are the shift weights and the coil spring. Whenever

engineRPMis increased, centrifugalforceis created,

causingtheshiftweights topushagainstrollers onthe

moveable sheave, which is held open by coil spring

preload. When this force becomes higher than the

preload in the spring, the outer sheave movesinward

and contacts the drive belt. This motion pinches the

drive belt between the spinning sheaves and causes

it to rotate, which in turn rotates the driven clutch.

At lower RPM, the drive belt rotates low in the drive

clutch sheaves. As engine RPM increases,

centrifugal force causes the drive belt to be forced

upward on drive clutch sheaves.

DRIVEN CLUTCH OPERATION

Driven clutches primarily sense torque, opening and

closing according to the forces applied to it from the

drive belt and the transmission input shaft. If the

torque resistance at the transmission input shaft is

greaterthanthe load fromthedrivebelt, thedrivebelt

is kept at the outer diameter of the driven clutch

sheaves.

Loading...

Loading...