CLUTCHING

6.13

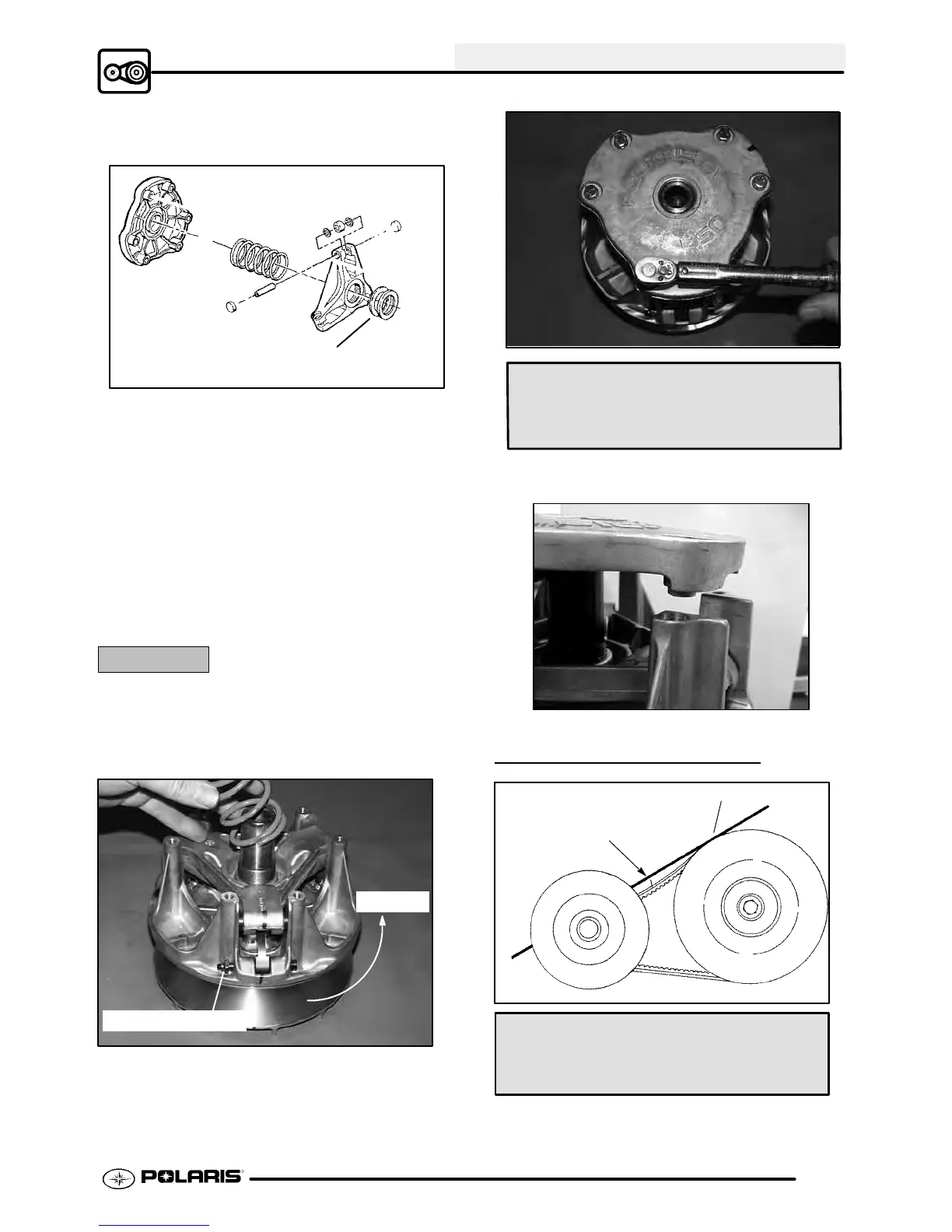

c) “X”, or the marks that were made earlier,

under weight

Spacer washers

2. Install moveable sheave onto fixed sheave.

3. Install spider spacers. Use same quantity and

thickness as were removed.

4. Compress spider buttons for each tower and

install spider, making sure that “X”, or the marks

that were made earlier, on spider aligns with “X”,

or the marks that were made earlier, in moveable

sheave.

5. Torque spider to specification using the holding

fixture and spider tool. Torque with smooth

motionto avoid damageto thestationary sheave.

Refer to Page 6.2 for torque specification.

CAUTION:

Be sure the spider spacer washers are fully seatedin

therecessedareainthespider. Anymisalignmentwill

alter clutch balance. Inverting the clutch while initially

tightening the spider will help position the washers.

Rotation

Nut on trailing side

6. Install shift weights using new lock nuts on the

bolts.

7. Reinstall clutch spring.

Spider Torque:

200 ft. lbs. (276 Nm)

Cover Screw Torque:

90 in. lbs. (10.4 Nm)

8. Reinstall cover, aligning bosses on the tower and

cover. Torque coverboltsevenlytospecification.

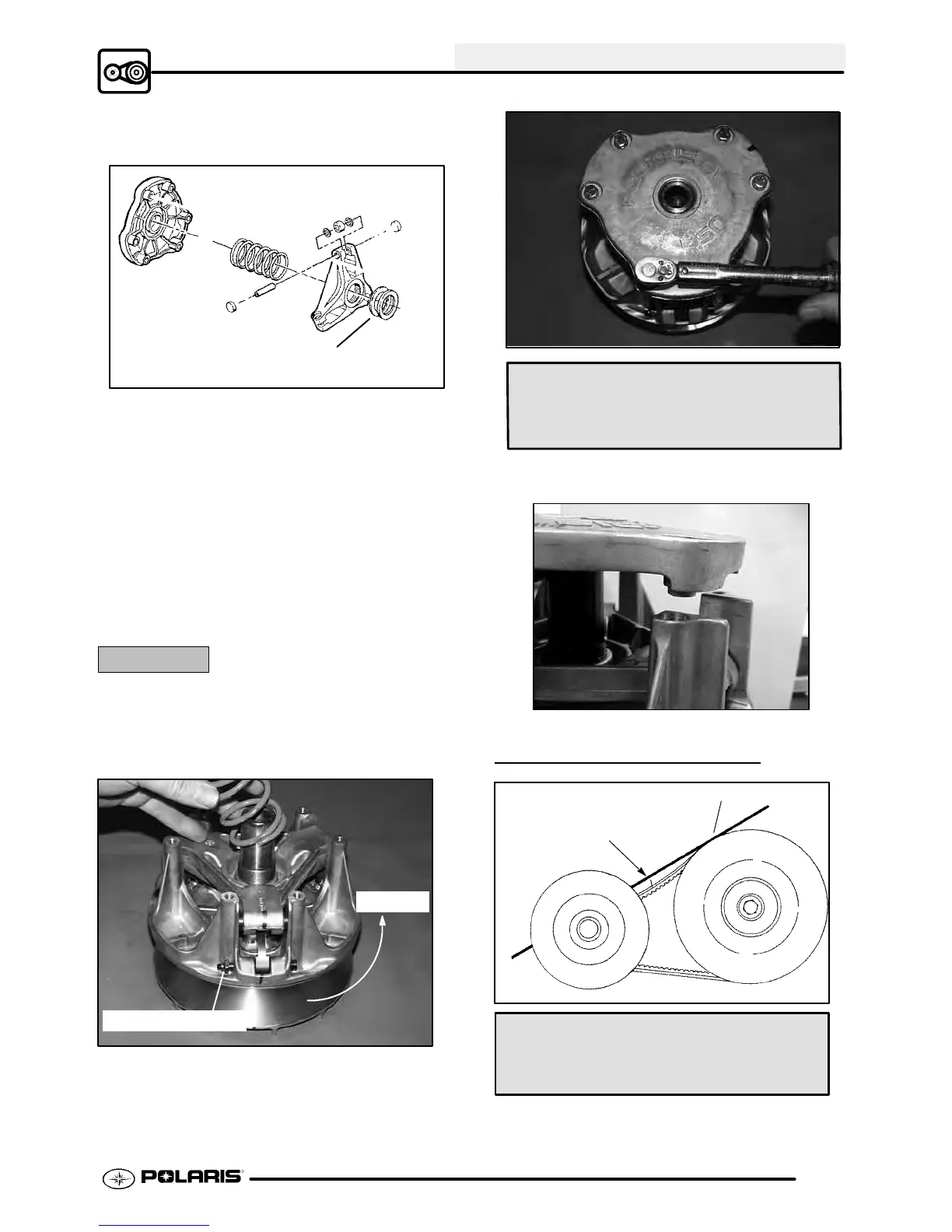

DRIVE BELT TENSION

11/8″ (28.5 mm)

Straight Edge

Belt Deflection (Tension):

11/8″ (2.9 cm) - 1 1/4″ (3.2 cm)

Loading...

Loading...