ENGINE

3.35

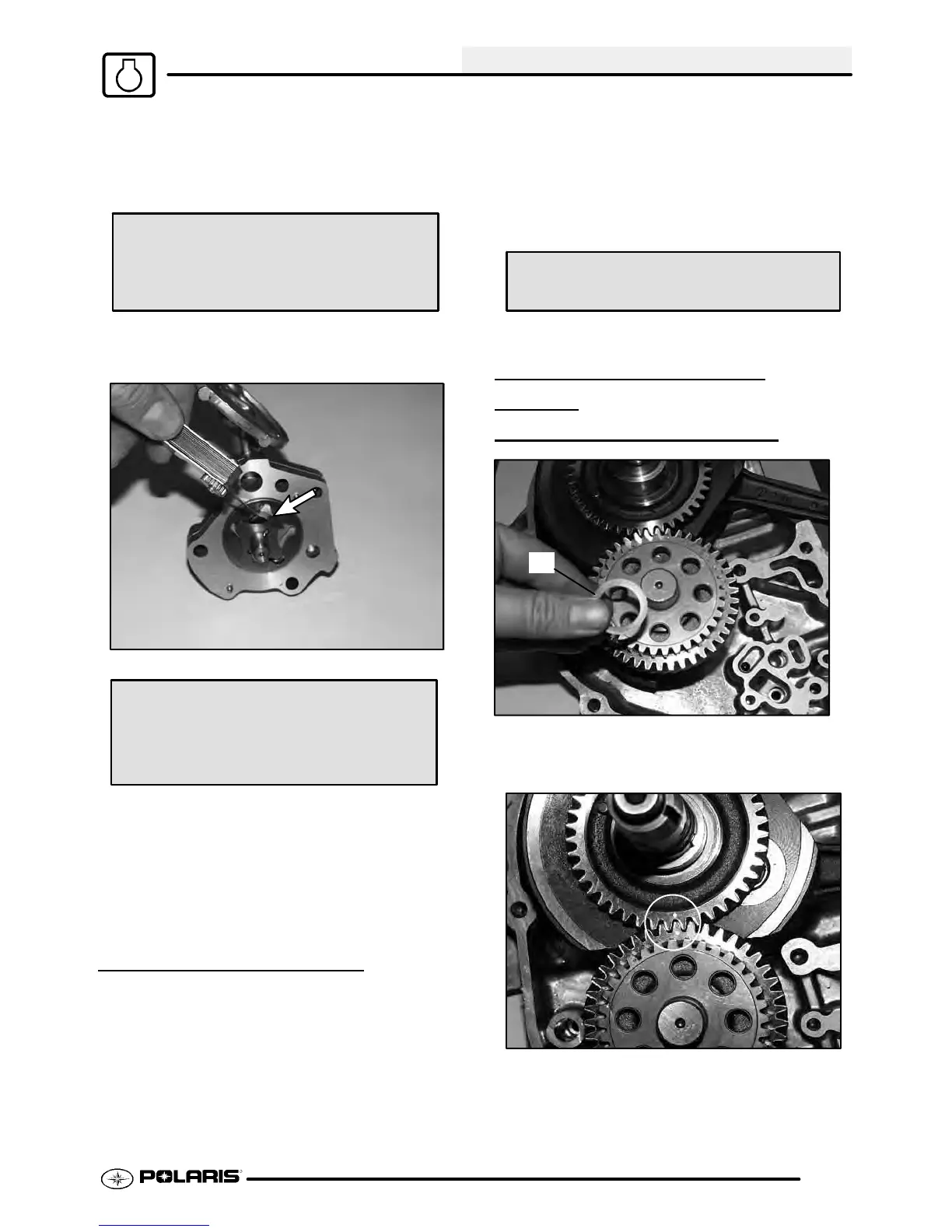

9. Measure pump end clearance using a feeler

gauge and straight edge.

Pump End Clearance:

Std: .001-.003 (.0254-.0762 mm)

Wear Limit: .004 (.1016 mm)

10. Measure clearance between outer feed rotorand

pump body with a feeler gauge.

Rotor Tip Clearance:

Std: .005 (.127 mm)

Wear Limit: .008 (.2032 mm)

11. Measure rotor tip clearance with a feeler gauge.

12. Remove inner and outer feed rotor and pump

chamber body.

13. Repeat measurements for scavenge rotor.

14. Remove inner and outer scavenge rotor and

inspect pump shaft for wear.

OIL PUMP ASSEMBLY

1. Clean and dry all parts thoroughly. Apply clean

engineoiltoall parts. Donot usegasketsealeron

the pump body mating surfaces or oil passages

will become plugged.

2. Install pump shaft and scavenge rotor drive pin.

3. Installouterscavengerotor,inner scavengerotor,

and scavenge casing.

4. Install outer feed rotor and inner feed rotor drive

pin.

5. Install inner feed rotor and feed chamber cover

with screw.

6. Tighten screw securely.

7. Install screen on pump body.

8. Installoilpumponcrankcaseandtorqueboltsto6

ft. lbs. (8 Nm).

Oil Pump Attaching Bolt Torque:

6 ft. lbs. (8 Nm)

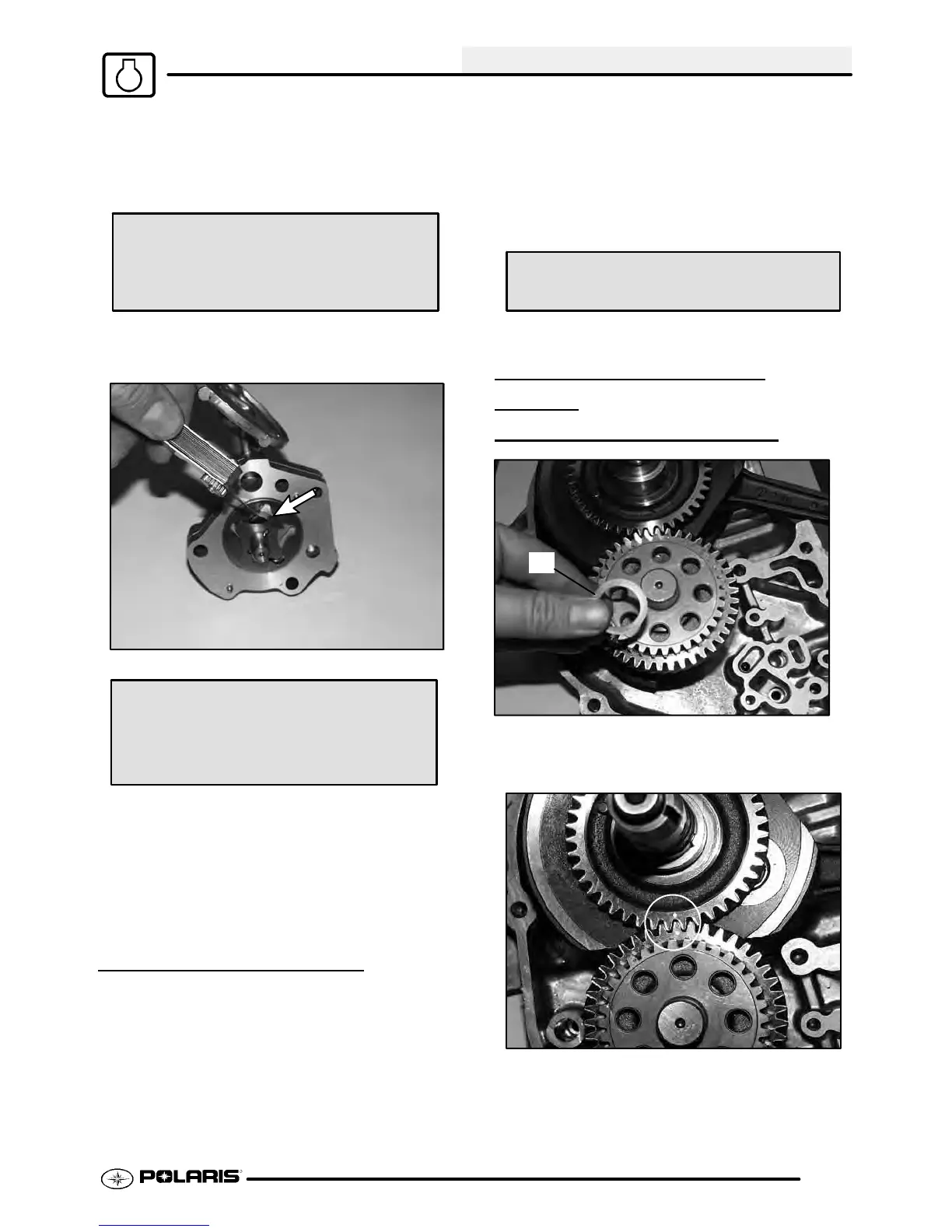

COUNTER BALANCER

SHAFT

REMOV

AL/INSPECTION

A

1. Remove the shim washer (A) from the counter

balancer shaft.

Loading...

Loading...