FUEL SYSTEM/CARBURETION

4.13

1.5 mm

.060″

Bowl Mating

Surface

2. Open bowl drain screw by turning

counterclockwise approximately two turns. Start

and run engine for 3 to 5 seconds to allow fuel

level to stabilize in the line. If level is out of

specification, removecarburetorand inspect inlet

needle and seat, float height, passages, etc.

NOTE: If a line was removed to perform this

procedure, it must be replaced.

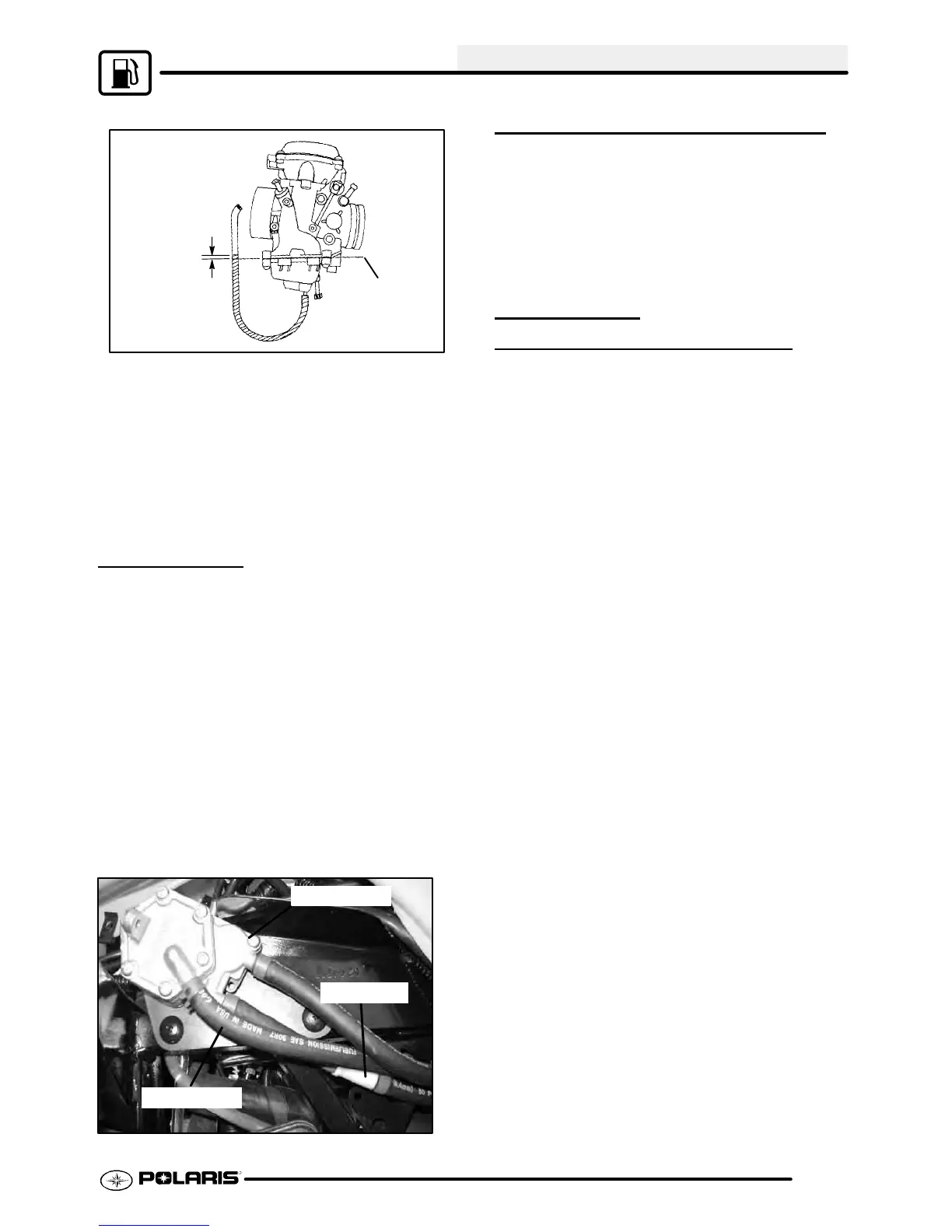

FUEL PUMP

This ATV is equipped with a pressure regulated fuel

pump (1-3 PSI). The pump is located under the left

front fender of the machine.

To test the fuel pump:

1. Turn fuel off.

2. Disconnect impulse line from pump.

3. Connect Mity-Vact (PN2870975) totheimpulse

line fitting on the pump.

4. Apply 5 inches (Hg) vacuum to the pump fitting.

The diaphragm should hold vacuum indefinitely.

If fuel is present in the impulse line or vacuum

chamber of thepump, the diaphragm is ruptured.The

pump diaphragms must be replaced.

Fuel Filter

Fuel Pump

Impulse line

FUEL PUMP DISASSEMBLY

1. Remove the screws from the pump diaphragm

cover. Notethelocationof the twolonger screws.

2. Remove the diaphragm cover gasket,

diaphragm, and valve body gasket.

3. Removetheoutletcheckvalvecover,diaphragm,

and gasket.

FUEL PUMP

INSPECTION/ASSEMBL

Y

1. Inspect inlet and outlet check valves for cracks,

warpage or damage. Inspect the diaphragms for

cracks, holes or swelling.

2. Toclean thevalvesor pumpbody, remove theset

screw and washer . Remove the valve and wash

with soap and water . Carburetor cleaner may be

used to clean the pump body when the check

valves are removed. CAUTION: Some

carburetor cleaners are very caustic and should

not be used to clean the non-metal parts of the

fuel pump.

3. Checkthesealing surfacesof thepumpbodyand

covers. Carefully remove all traces of old gasket

and check the surfaces for damage. Replace

diaphragms and gaskets as a set.

4. Reassemble the pump in the reverse order of

disassembly. Tighten all screws evenly.

Loading...

Loading...