ENGINE

3.49

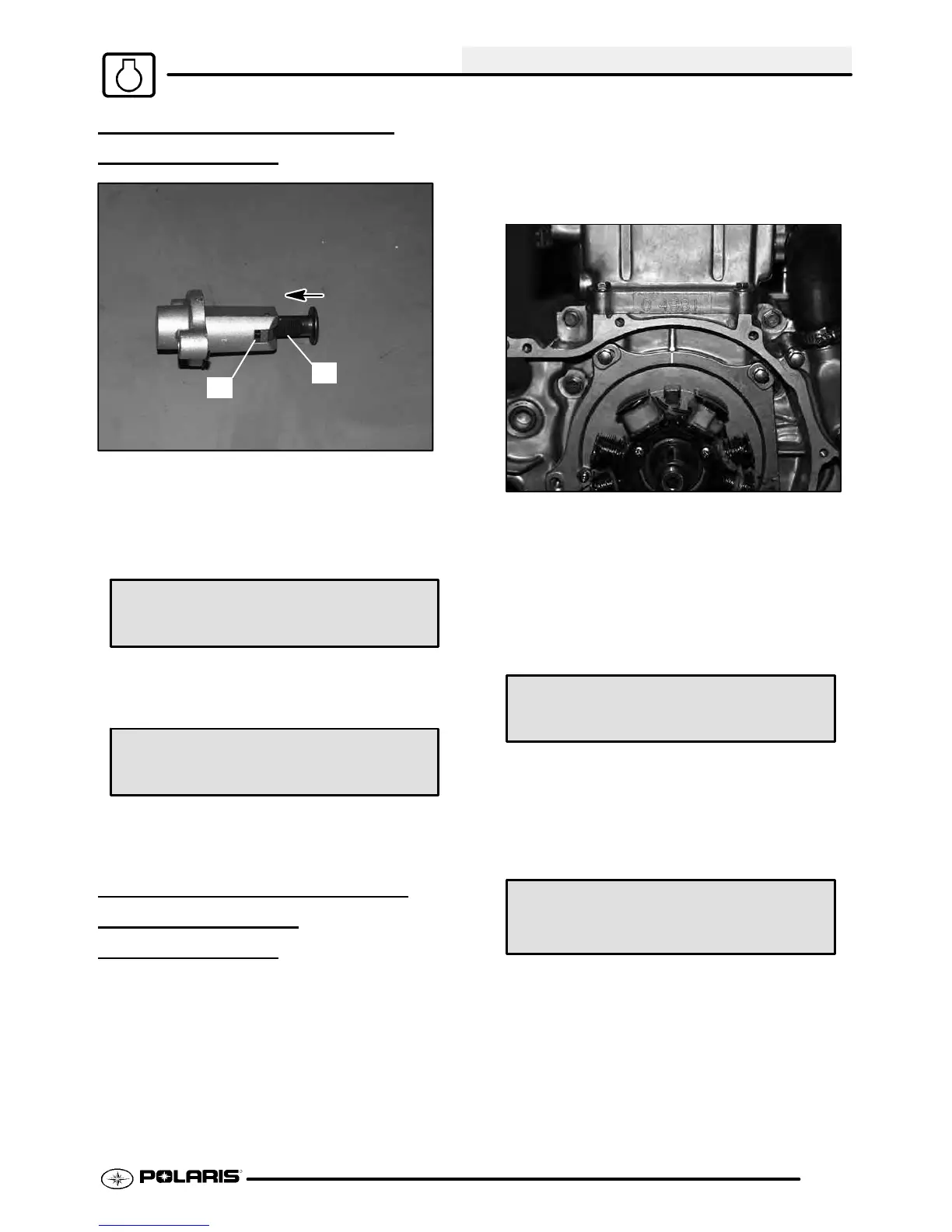

CAM CHAIN TENSIONER

INSTALLA

TION

B

A

1. Release the ratchet pawl (A) and push the

tensioner plunger (B) all the way into the

tensioner body.

2. Install the tensioner body with a new gasket and

tighten the bolts.

Tensioner Bolt Torque:

6 ft. lbs. (8 Nm)

3. Install the spring, new sealing washer , and

tensioner plug.

Tensioner Plug Torque:

17 ft. lbs. (23 Nm)

4. Slowly rotate engine two to three revolutions and

re-check cam timing.

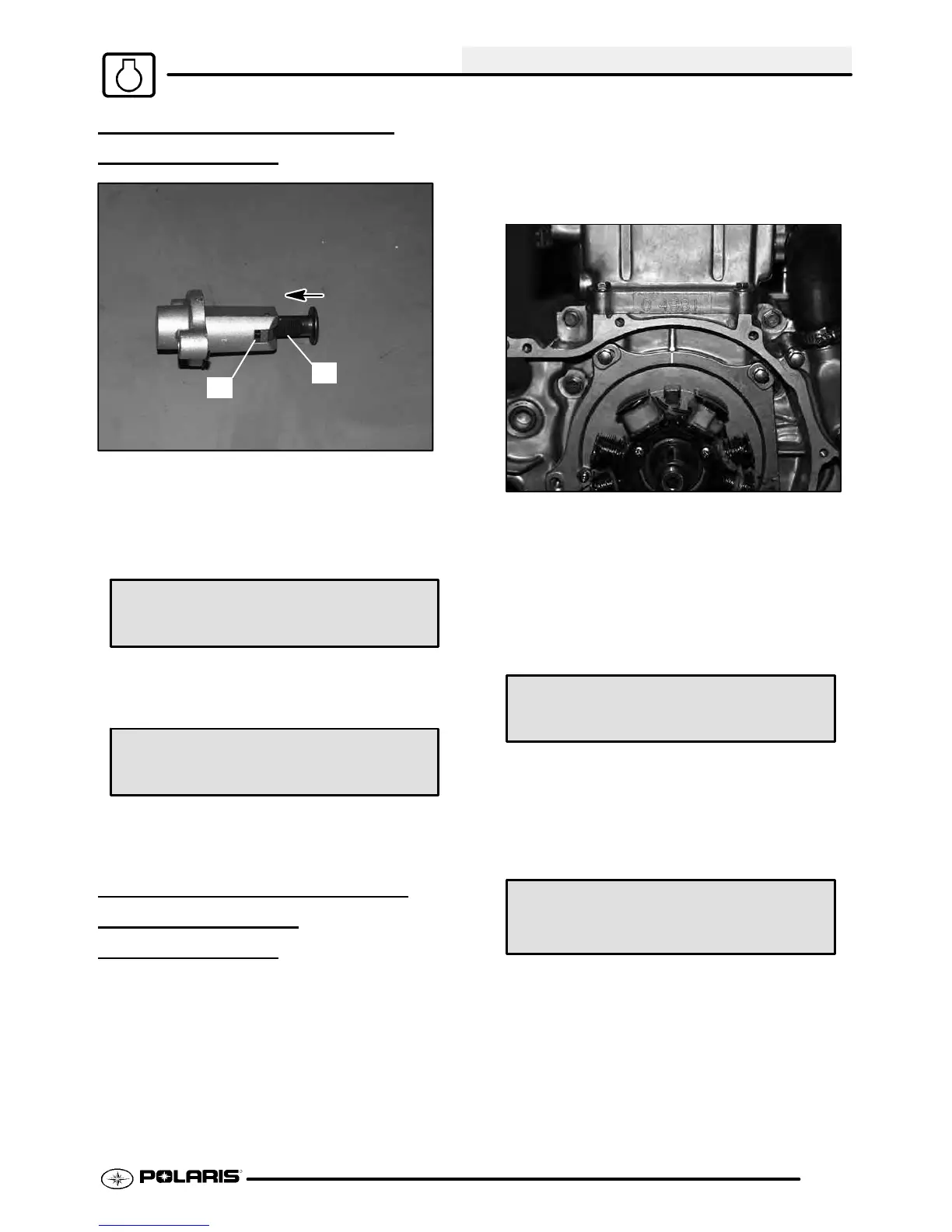

STATOR, FLYWHEEL AND

STARTER

DRIVE

INSTALLA

TION

NOTE: The stator ,flywheel, starter drive, and recoil

can be assembled with the engine in the frame.

Stator

1. Applya light film of grease to the crankshaft seal.

Apply molybdenum disulfide grease or assembly

lubricant to the crankshaft bushing.

2. Install a new O-Ring in the oil passage recess in

the crankcase.

3. Apply 3 Bond 1215 (PN 2871557)oran

equivalent sealer tothe stator plate outer surface

and install a new O-Ring.

4. Installthestatorplatebeingcarefulnottodamage

the seal. Align timing reference marks on the

plate and crankcase. Be sure the plate is fully

seated.

NOTE: Thisis a statictimingmark. Strobetiming

should be performed after start up.

5. Torque bolts evenly to specification.

Stator Plate Bolt Torque:

5-6.5 ft. lbs. (7-9 Nm)

6. SealstatorwiregrommetwithCrankcaseSealant

(PN 2871557) or equivalent sealer.

Flywheel

1. Installflywheel,washer,andnut. Torqueflywheel

to specification.

Flywheel Nut Torque:

58-72 ft. lbs. (78-98 Nm)

Loading...

Loading...