MAINTENANCE

2.23

RADIATOR

1. Check radiator air passages for restrictions or

damage.

2. Carefully straighten any bent radiator fins.

3. Remove any obstructions with compressed air or

low pressure water.

COOLING SYSTEM

PRESSURE

TEST

Refer to Page 3.6 for pressure test procedure.

COOLANT LEVEL

INSPECTION

W ARNING

Never remove the radiator pressure cap when the

engineiswarmorhot. Escapingsteamandfluidcan

causesevereburns. Theenginemustbe allowedto

cool before removing the pressure cap.

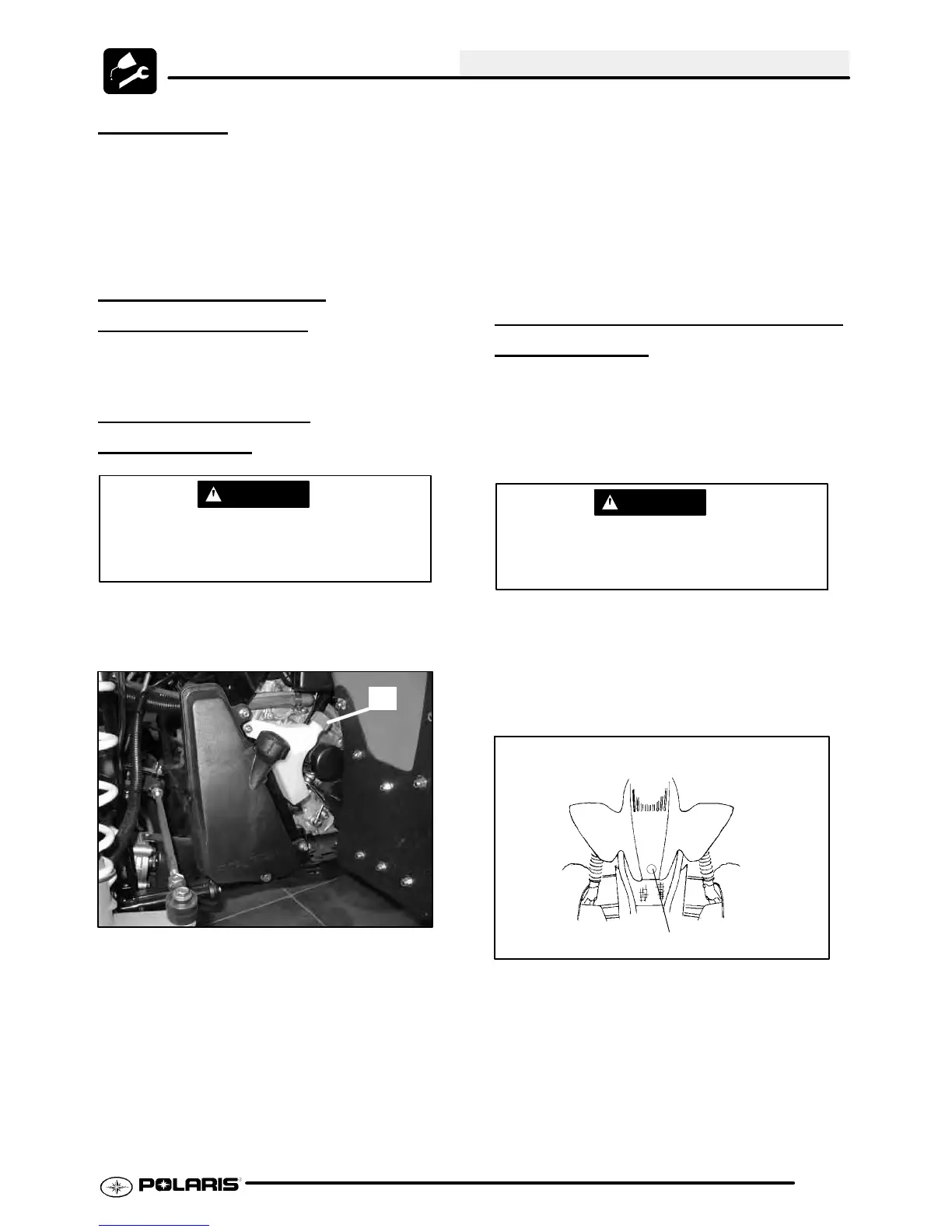

Therecover ybott le(A) ,locat edont helef ts ideoft he

machine,mus tbemaintainedbetweentheminimum

and m axim um levels.

A

Withthe engineat operatingtemperature, thecoolant

level should be between t he upper and lower m ar ks

on t he coolant reser voir. If it is not:

1. Remove reservoir cap. Verify the inner splash

cap vent hole is clear and open.

2. Fill reservoir to upper mark with Polaris Premium

60/40 Anti Freeze / Coolant (PN 2871323)ora

mixture of antifreeze and distilled water as

required for freeze protection in your area.

3. Reinstall cap.

NOTE: If overheating is evident, allowsystemto cool

completely and check coolant level in the radiator.

Inspect for signs of trapped air in system.

RADIATOR COOLANT LEVEL

INSPECTION

NOTE: This procedure is only required if the cooling

system has been drained for maintenance and/or

repair . However, if the recovery bottle has run dry, or

if overheating is evident, the level in the radiator

should be inspected and coolant added if necessary.

W ARNING

Never remove the radiator pressure cap when the

engineiswarmorhot. Escapingsteamandfluidcan

causesevereburns. Theenginemustbe allowedto

cool before removing the pressure cap.

NOTE: Use of a non-standard pressure cap will not

allow the recovery system to function properly.

To access the radiator pressure cap:

Remove front cover by placing your fingers under the

front of the cover and pull upward.

Pressure Cap

Loading...

Loading...