23

PORA ELECTRIC MACHINERY CO.,LTD.

PR-DTC-4100.A / AD

6. P·I·D Sensitivity setting

※P·I·D needs to be adjusted when control output in automatic mode responds too fast or too late.

※ Before setting, [Possible to set P·I·D while in operation] at first article of the Dip switch from board side

should be ON. (Refer to page 11~12.)

0.0kg

0.0kg

0.0mpm 100.0mm

T

5.8%

~

[PID SET] P: 2.0% I: 1.0% D: 0.1%

1) When pressing [Dial button] longer in automatic mode, it gets to

enter P·I·D setting mode.

2) P·I·D sensitivity figures will be shown at the below of a display.

3) Please adjust figures of each sensitivity using [Up/down/left/right

button] with checking the reacting condition of control output.

4) If the adjustment is done, press [Dial button] longer to exit P·I·D

sensitivity setting mode.

5) After setting is completed, please OFF at first article of a Dip switch

from board side.

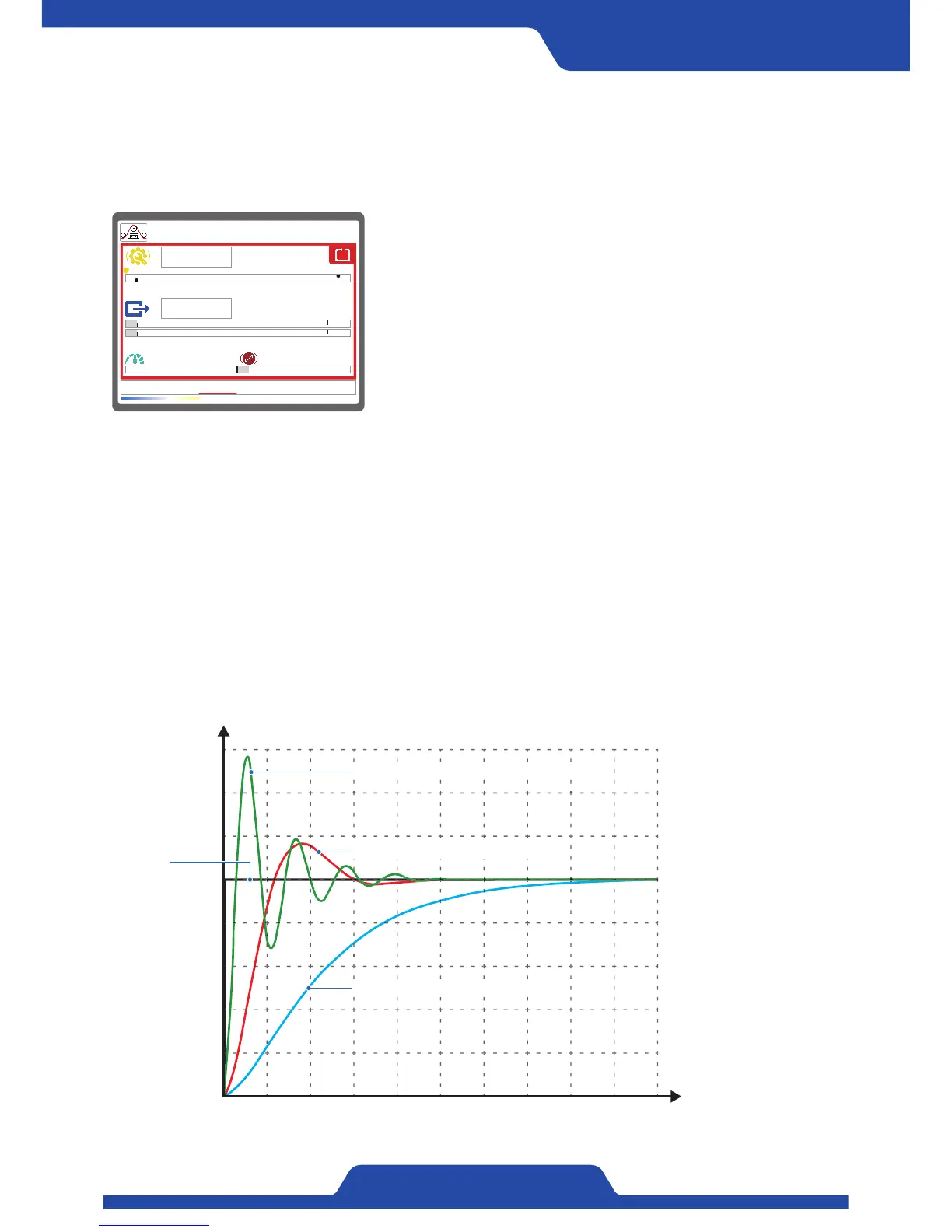

- P Control (Proportional control: Gain)

It generates control output which is proportionate to tension error. It can control stably than ON/OFF control and

can decrease the time to reach target value but there is always a normal state error (An error between actual

tension and target tension).

- I Control (Integral control: Stability)

To get rid of a normal state error, it reflects control output by accumulating tension error. The less the setting

values are, it can secure stability, however it will take much time to reach target value. So it needs to adjust

appropriate figure.

- D Control (Differential control: Response)

It reflects control output by setting the change of tension error to set an error value. It puts on the brakes sudden

change to decrease overshoot and improve stability.

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

Tension

(kg)

0 2 4 6 8 10 12 14 16 18 20 Time (sec)

Very fast response and poor stability

Easy stability and medium speed

Very stable but late response

Set

point

※NOTE

Please set within the range which is not much different from the factory setting value.

Loading...

Loading...