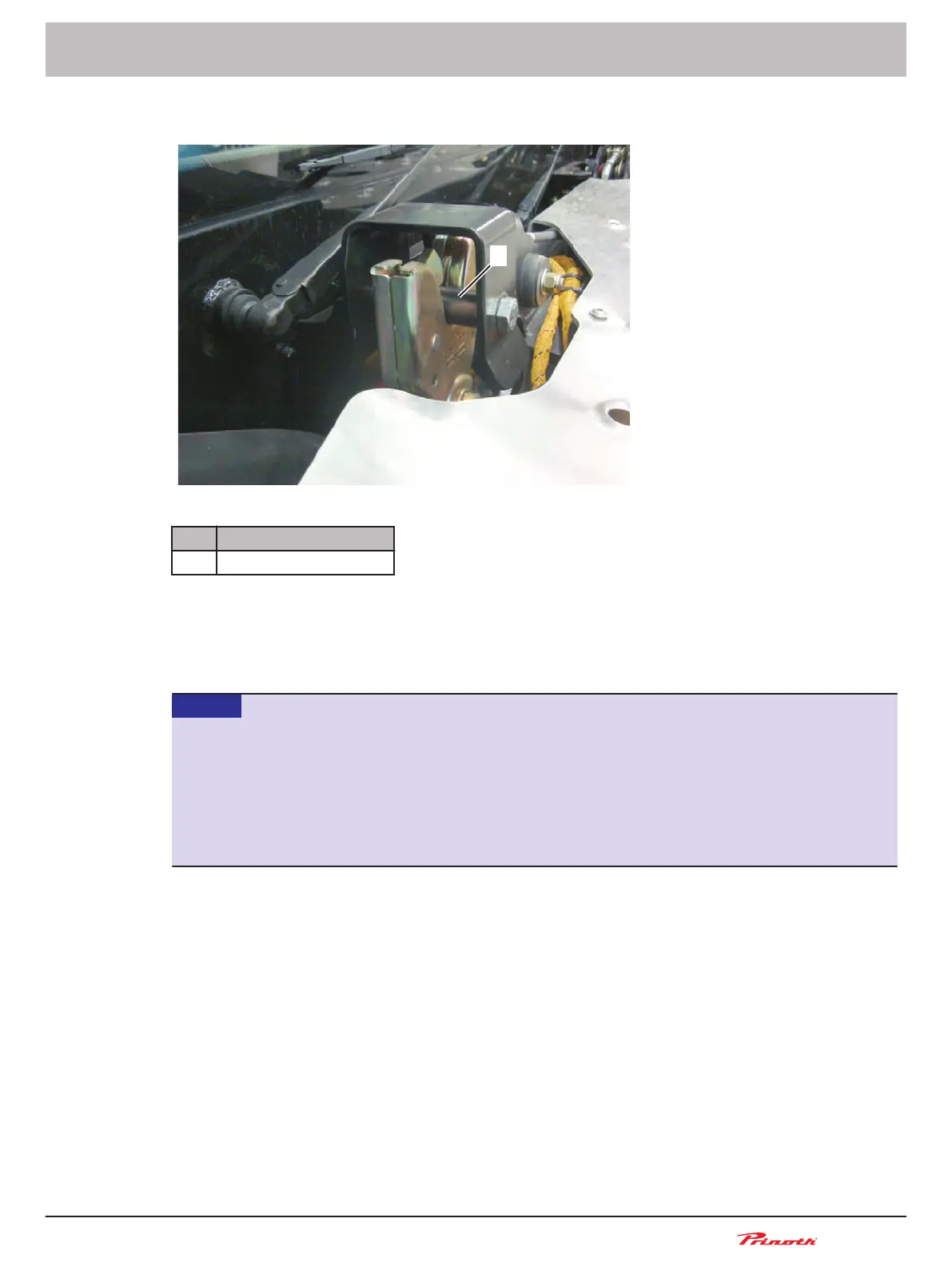

Verification of the cab locking pins

Figure 92: Cab locking hardware

Pos. Name

1 Cab locking pins (qty 2)

When the cab is raised for maintenance, ensure the pins at the back of the cab can rotate freely. Jam-

med pins could cause premature wear of the cab locking system.

Lubrication points

NOTICE

Risk of damage to property

Failure

to observe the lubrication intervals or to use the approved lubricants may cause damage to

property.

► Observe the specified lubrication intervals

► Clean lubricating fittings before lubricating

► Replace damaged lubricating fittings immediately

■ The

required lubrication intervals are indicated on the maintenance schedule. Grease the lubrica-

tion points indicated with arrows on the following drawings, as well as the hydraulic cylinders for

tilting the cab and load platform.

■ Before lubricating, thoroughly clean the lubricating fittings in order to prevent dirt or foreign matter

from entering.

■ Damaged lubricating fittings are to be replaced immediately. Press the specified lubricating

grease through the fitting until all the old grease has been evacuated.

Snow groomer BISON

Operating and Maintenance Manual

BISON 908930245 - 30367

11 - Maintenance

155 (255)

11.5

11.6

Loading...

Loading...