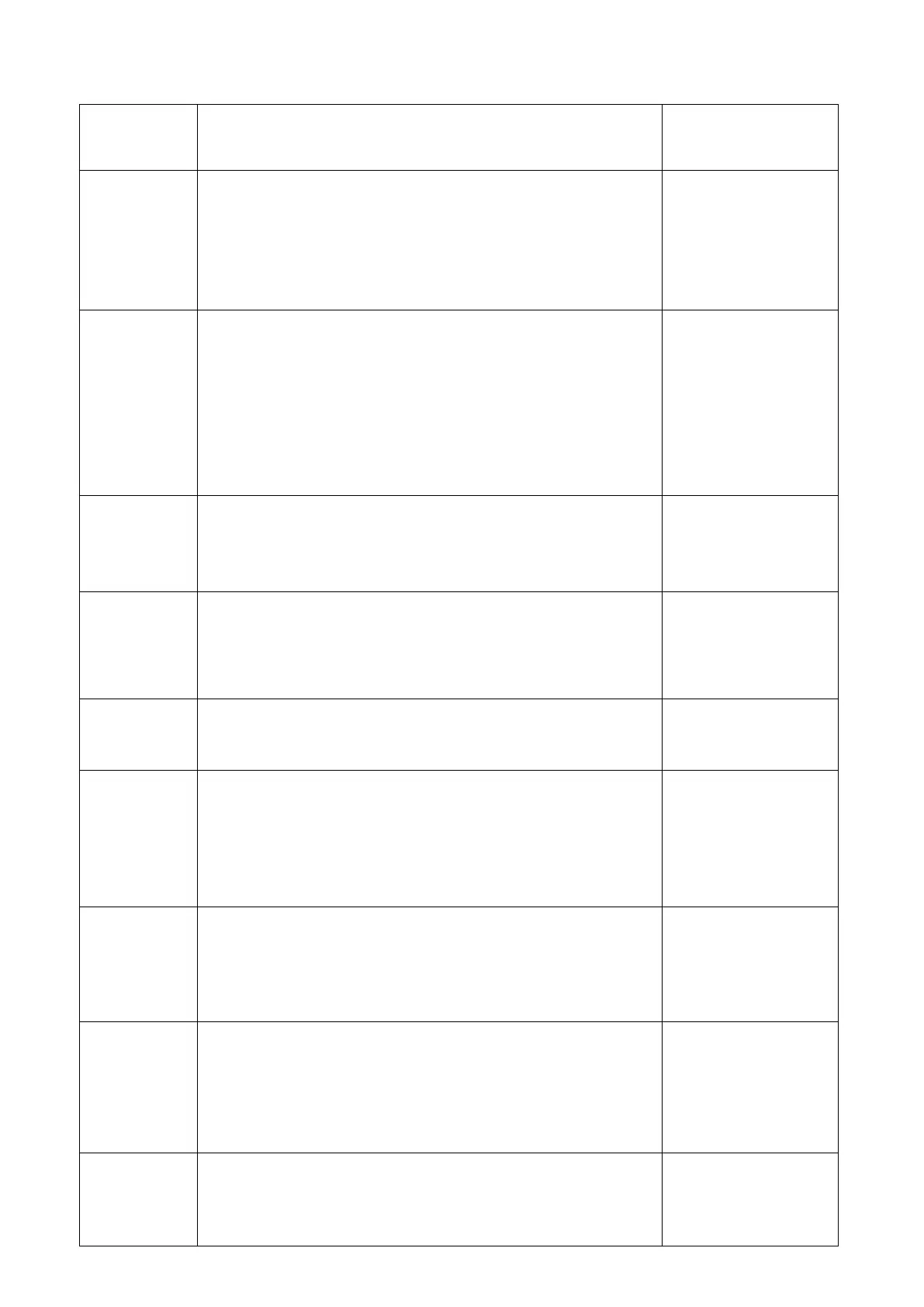

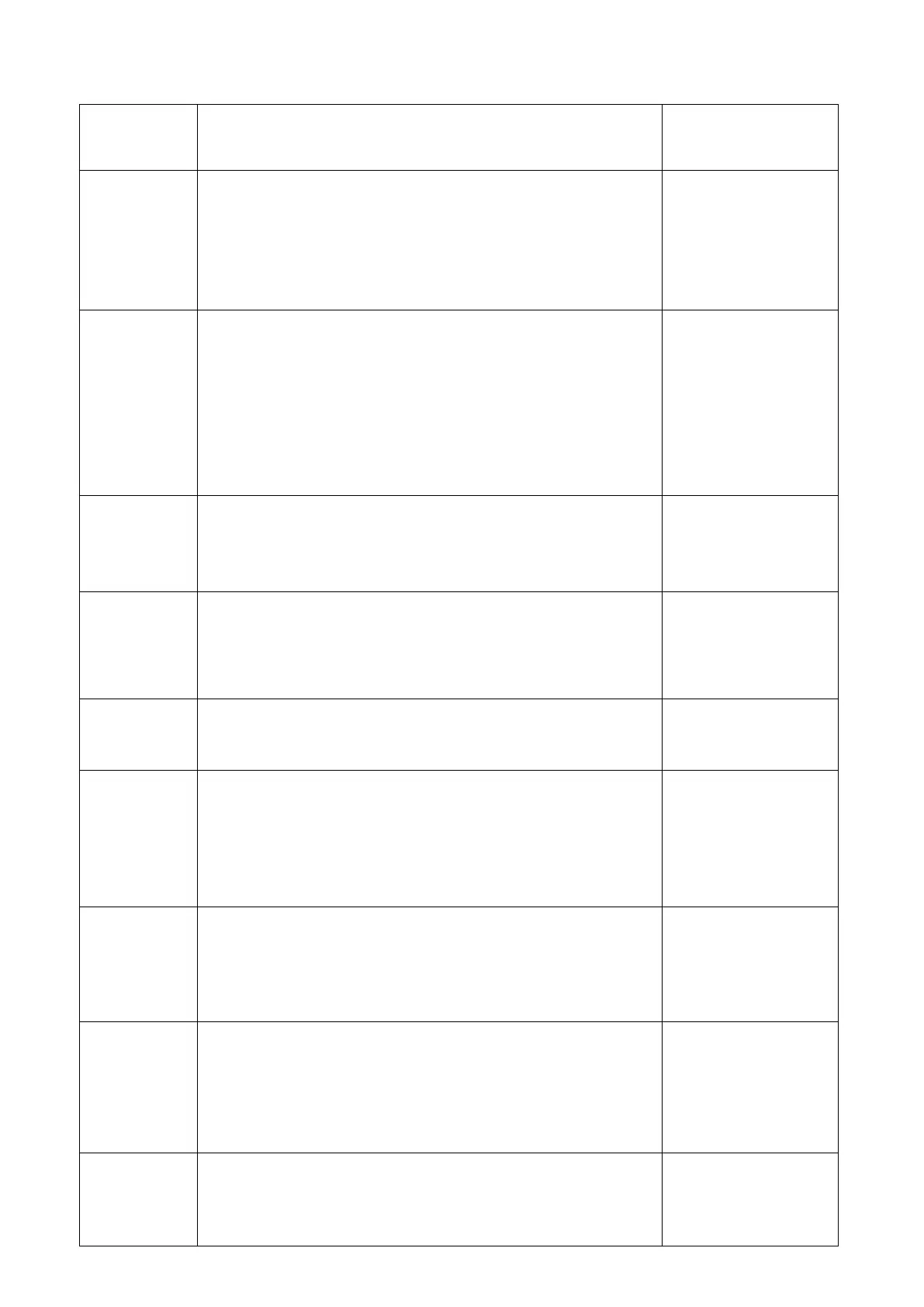

79

system.

The system must be powered off when cleaning dust.

content of the

environment in which it

is used).

Power circuit

connection

check

(1) Check power cable connections for looseness and retighten to the

torque specified above.

(2) Check power cables and control cables for damage, especially cut

marks on the skin in contact with metal surfaces.

(3) Check that the insulating wraps of the power cable terminals are not

detached.

Officially run for six

months, then every six

months to one year

thereafter.

Terminal and

wiring

connection

check

(1) Check whether the control terminal screws are loose and tighten them

with a screwdriver.

(2) Check whether there is any color change in the wiring copper or

screws.

(3) Visually inspect the connections such as equipment terminals and the

distribution of wiring.

(4) Check the main circuit terminals for poor contact and screw locations

for signs of overheating.

Officially run for six

months, then every six

months to one year

thereafter.

Circuit breaker

maintenance

(1) Routine inspection of all metal components for corrosion.

(2) Annual inspection of contactors (auxiliary switches and micro-

switches) to ensure that they are in good mechanical working order.

(3) Check the operating parameters (especially voltage and insulation).

Officially run for six

months, then every six

months to one year

thereafter.

SPD check

(1) Annual inspection of cable connection to ensure that they are in

good mechanical working order.

(2) Check the operating parameters (especially voltage and insulation).

Every 6 months to 1 year

Fuse check

(1) Annual inspection of cable connection to ensure that they are in

good mechanical working order.

(2) Check the operating parameters (especially voltage and insulation).

Every 6 months to 1 year

Battery

maintenance

(1) Perform normal charging and discharging operations on the battery

system to check whether there are any abnormalities in the operating

status of the battery, and to check whether the battery system indicator

status is normal.

(2) It is recommended that the battery be fully charged and equalized on

a regular basis.

Every 6 months to 1 year

Aerosol fire

extinguisher

inspection

When the fire extinguishing equipment is in normal working condition, it

is necessary to check the starting device (JR10 starter box, etc.) to make

sure that the line is normal.

The fire extinguishing equipment is maintenance-free for its own validity

period.

Officially run for six

months, then every six

months to one year

thereafter.

Air conditioner

maintenance

(1) Check whether the temperature of the air outlet is close to the cooling

setting value, ±2℃.

(2) Check the degree of dust at the air inlet and outlet. And use a

compressed air machine to clean and treat the dust at the air conditioner

inlet and outlet.

Ranges from quarterly,

semi-annually or once a

year (depending on the

dust content of the

environment in which it

is used).

Display

maintenance

(1) Check the display for water ingress and see if the display shows

normally without color change.

(2) Test the display to see if it responds normally to switching and

selecting content.

Every 6 months to 1 year

Loading...

Loading...