10 | Gas connection for gas units

80.06.083_iCombiPro-iCombiClassic_IM_en-US 81 / 100

n

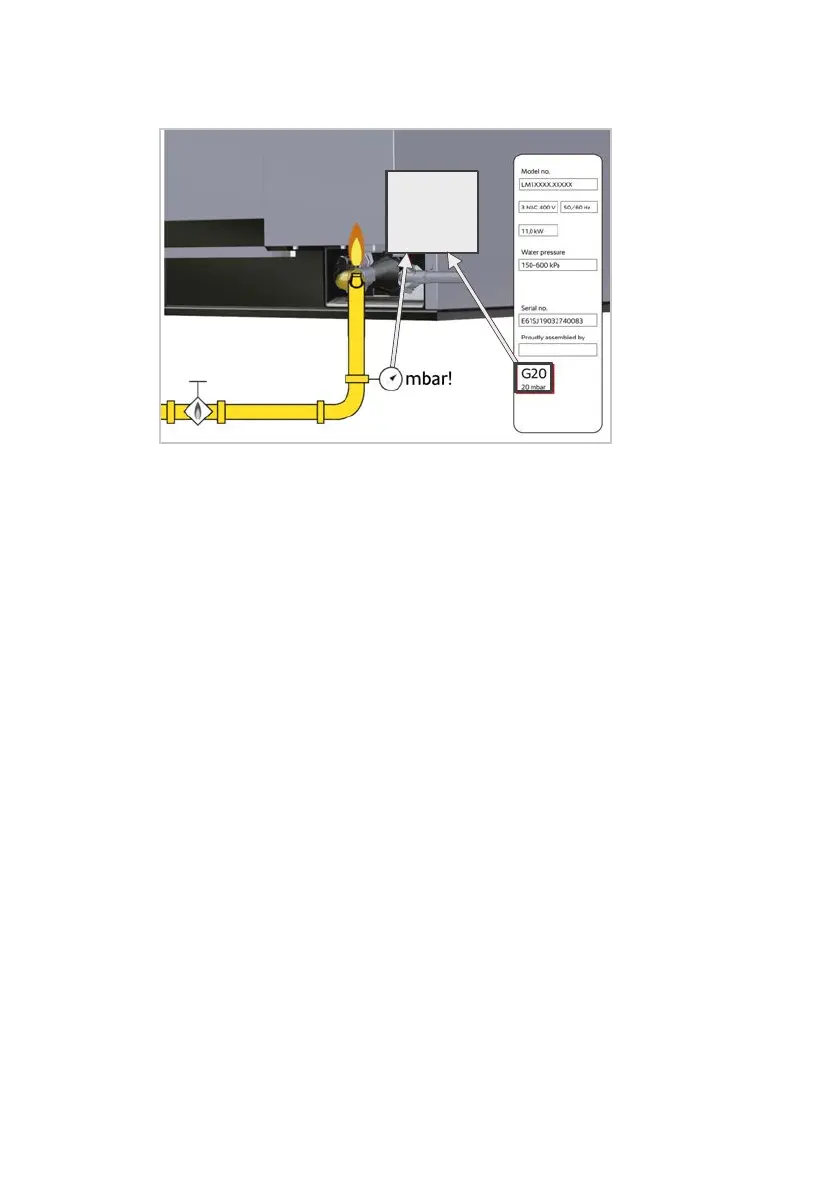

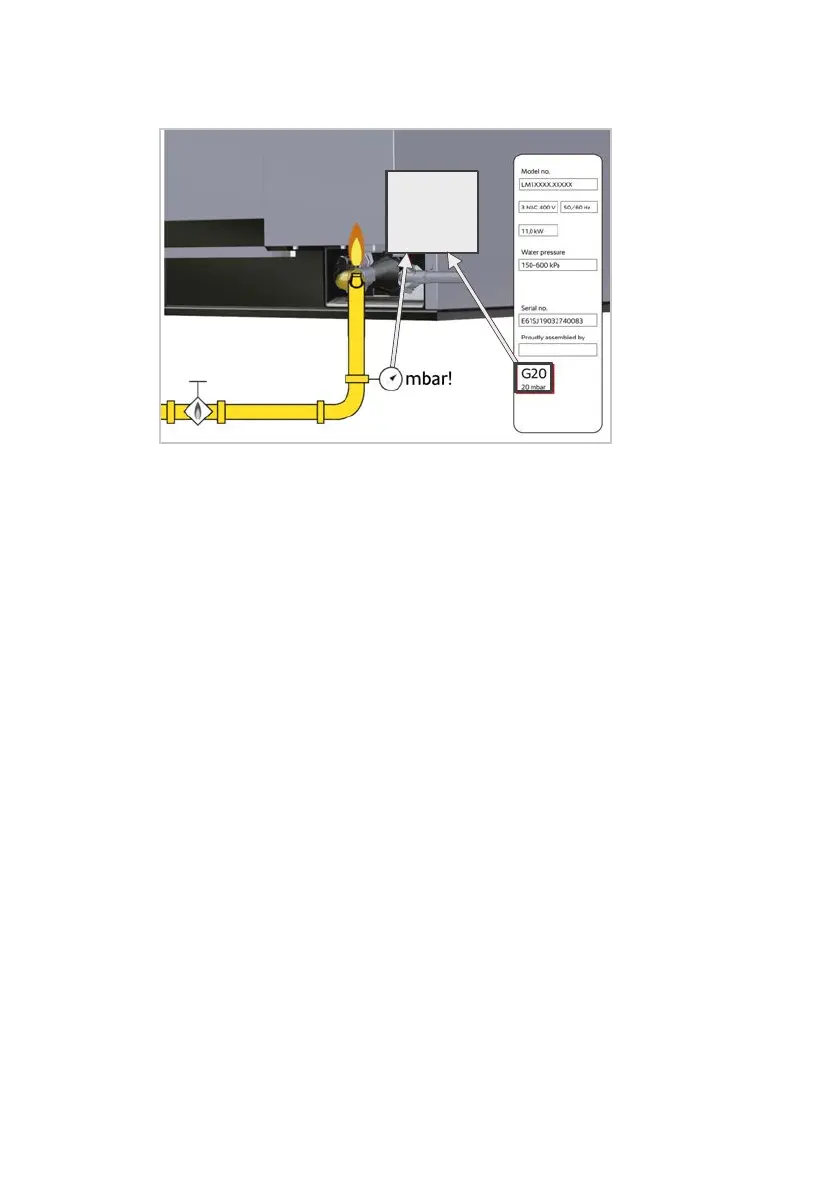

The gas type and the dynamic connection pressure set in the unit must

match the specifications on the type plate.

n

If the line pressure deviates from the connection flow pressure of the unit,

contact your gas supply company.

n

Observe the regulations of the local gas supply company.

Requirements for gas supply and gas lines

n

The flue gas analysis may only be carried out by a technician authorized by

the manufacturer. The flue gas analysis must be carried out before commis-

sioning.

n

The gas connection may only be carried out by a locally approved gas in-

staller.

n

The gas connection line must be designed for the nominal heat load speci-

fied on the type plate.

n

The gas supply and gas distribution in the unit must be checked for leaks us-

ing a suitable gas leak detector.

n

The cross-section of the gas line must be designed for the maximum con-

nected power of all consumers, at least ¾ inch for a single unit, line size

must increase with increased number of units on same line.

n

A gas shut-off valve must be installed upstream of each unit.

n

All on-site connection parts must be tested in accordance with DIN-DVGW

(the local regulations).

The hose for the gas connection must not be longer than 2.0m [78 3/4

inch].

n

The gas line can be connected to a gas socket.

n

A connection with the appropriate counterpart to the ¾inch internal thread

(RP thread) is required to connect the gas line.

n

The unit must be secured against slipping (safety cable restraint)

Loading...

Loading...