3 - WEIGHING

16

3.4.2 Set Target Weight

The target weight is set automatically to the value programmed in field 2 of the selected 'Truck' index (a blank

field sets a zero target weight).

After completing the store selection and returning to the MAIN screen, you can manually enter a different target

weight if required.

3.5 Error Messages

3.5.1 Angle of Slope

This indicates that the angle of slope is too great in a particular

direction - move to a more level area.

3.5.2 Low Oil Temperature / Sensor Faults

The instrument also warns you of low oil temperature or a sensor fault

and inhibits the zero routine.

3.5.3 Anti-bounce

Caused by excessive bouncing of the loader whilst weighing. The

screen prompts "To Much Bounce - Lift Again".

3.5.4 Maximum Weight Exceeded

flashes on-screen with a 3-second continuous beep when the

maximum weight limit is exceeded. This will occur 9 divisions (9 x e)

above the stated maximum figure that the system is certified to.

Weighing is inhibited in NAWI or AWI mode.

Example: If Max weight = 10.0t and 'e' = 0.05t,

the Alarm weight = 10.45t.

3.6 Zero Alarms

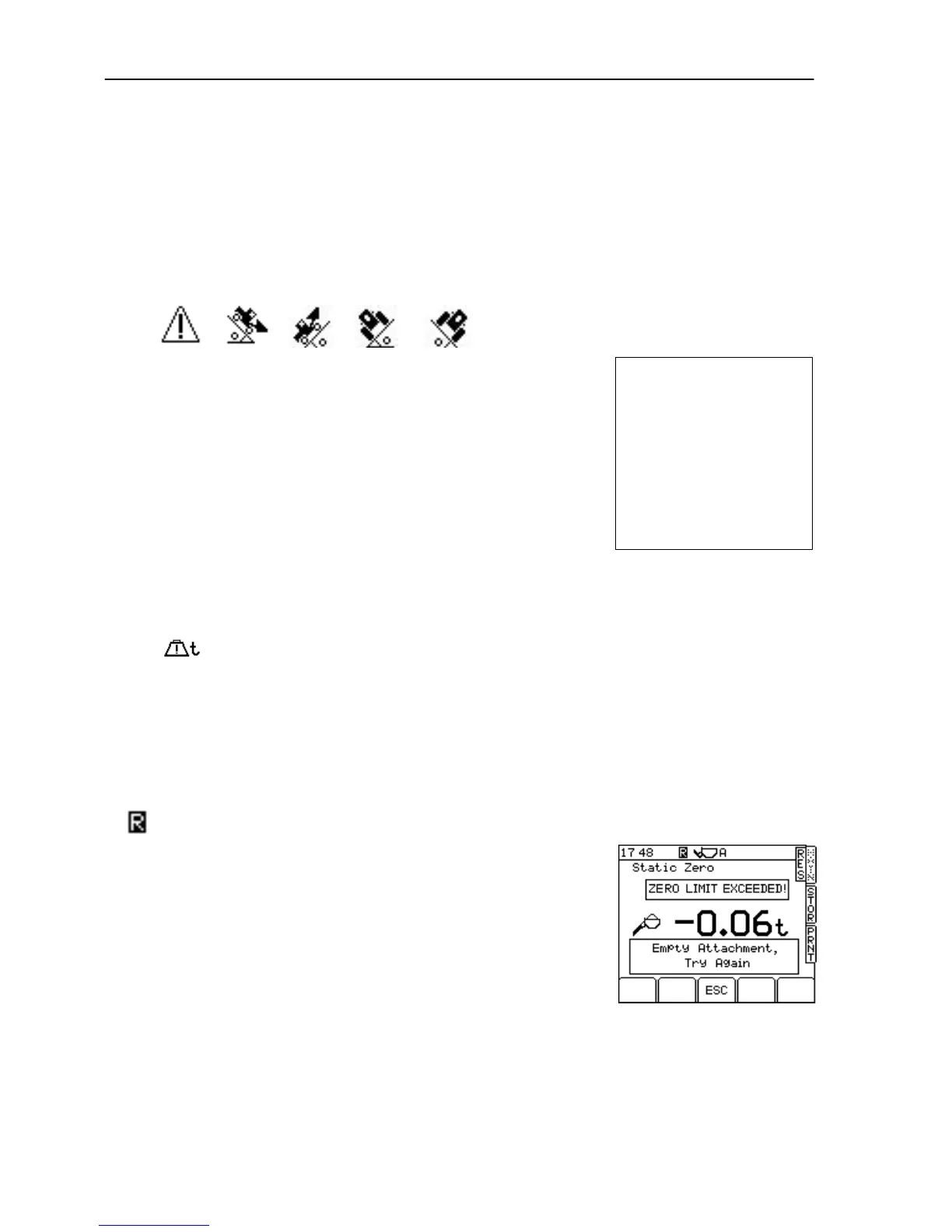

Zero Limit Exceeded (more than ±2% drift)

When a zero procedure is performed in normal use, the instrument

automatically detects if the Zero readings have moved more than ± 2

% of the maximum weight, from the Zero set at the first Zero after

switch on (fig. 22b).

This prompt is designed to alert the operator that there could be a build

up of material in the bucket, and automatic confirmation of the Zero is

inhibited. Clean out the bucket as necessary.

Example zero limits are:

for 2000kg max. weight: -±40kg

for 5000kg max. weight: -±100kg

for 10000kg max. weight: -±200kg

Loading...

Loading...