City Series CV40E-12 | 55

installation

Gas Pipe Pressure Testing

The appliance must be isolated from the gas sup-

ply piping system by closing its individual manual

shut-o valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig. (3.45 kPa). Disconnect

piping from valve at pressures over 1/2 psig.

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1 Make sure the unit is in the "OFF" position.

2. Loosen the "IN" and/or "OUT" pressure tap(s),

turning counterclockwise with a

1/8" wide at screwdriver.

3. Attach manometer to "IN" and/or "OUT" pres-

sure tap(s) using a 5/16" ID hose.

4. Turn the unit on with the remote or wall switch

5. The pressure check should be carried out with

the unit burning and the setting should be within

the limits specied on the safety label.

6. When nished reading manometer, turn o

the unit, disconnect the hose and tighten the

screw (clockwise) with a 1/8" at screwdriver.

Note: Screw should be snug, but do not

over tighten.

High Elevation

This unit is approved for altitude 0 to 4500 ft.

(CAN1 2.17-M91).

Gas Line Installation

Since some municipalities have additional local

codes it is always best to consult with your local

authorities and the CAN/CGA B149 installation code.

For USA installations follow local codes and/or

the current National Fuel Gas Code, ANSI Z223.1.

When using copper or ex connectors use only

approved ttings. Always provide a union so that

gas lines can be easily disconnected for servicing.

Flare nuts for copper lines and ex connectors are

usually considered to meet this requirement.

NOTE: A shuto / dante valve should be

supplied in or near the unit (or as per local

codes) for ease of servicing this appliance.

IMPORTANT: Always check for gas leaks with

a soap and water solution or gas leak detec-

tor. Do not use open ame for leak testing.

CV40E-12 NG System Data

Min. Supply

Pressure

5" WC (1.25 kpa)

Manifold Pressure 3.8" WC (0.94 kpa)

Orice Size #42 DMS

Maximum Input 28,500 Btu/h

(8.33 kW)

Minimum Input 15,500 Btu/h

(4.54 KW)

CV40E-12 LP System Data

Min. Supply Pressure 11" WC (2.73 kpa)

Manifold Pressure 10.5" WC (2.62 kpa)

Orice Size #53 DMS

Maximum Input 28,500 Btu/h

(8.35 kW)

Minimum Input 15,500 Btu/h

(4.54 KW)

Note: If you have an incorrect ame

pattern, contact your Regency

®

dealer for further instructions.

Incorrect ame pattern will have small,

probably yellow ames, not coming into

proper contact with the rear burner or ame

sensor.

Burner

Flame Sensor

Pilot

Ignitor

Pilot Adjustment

Periodically check the pilot ames. Correct

ame pattern has two strong blue ames:

1 owing around the ame sensor and 1

owing across the burner (it does not have

to be touching the burner).

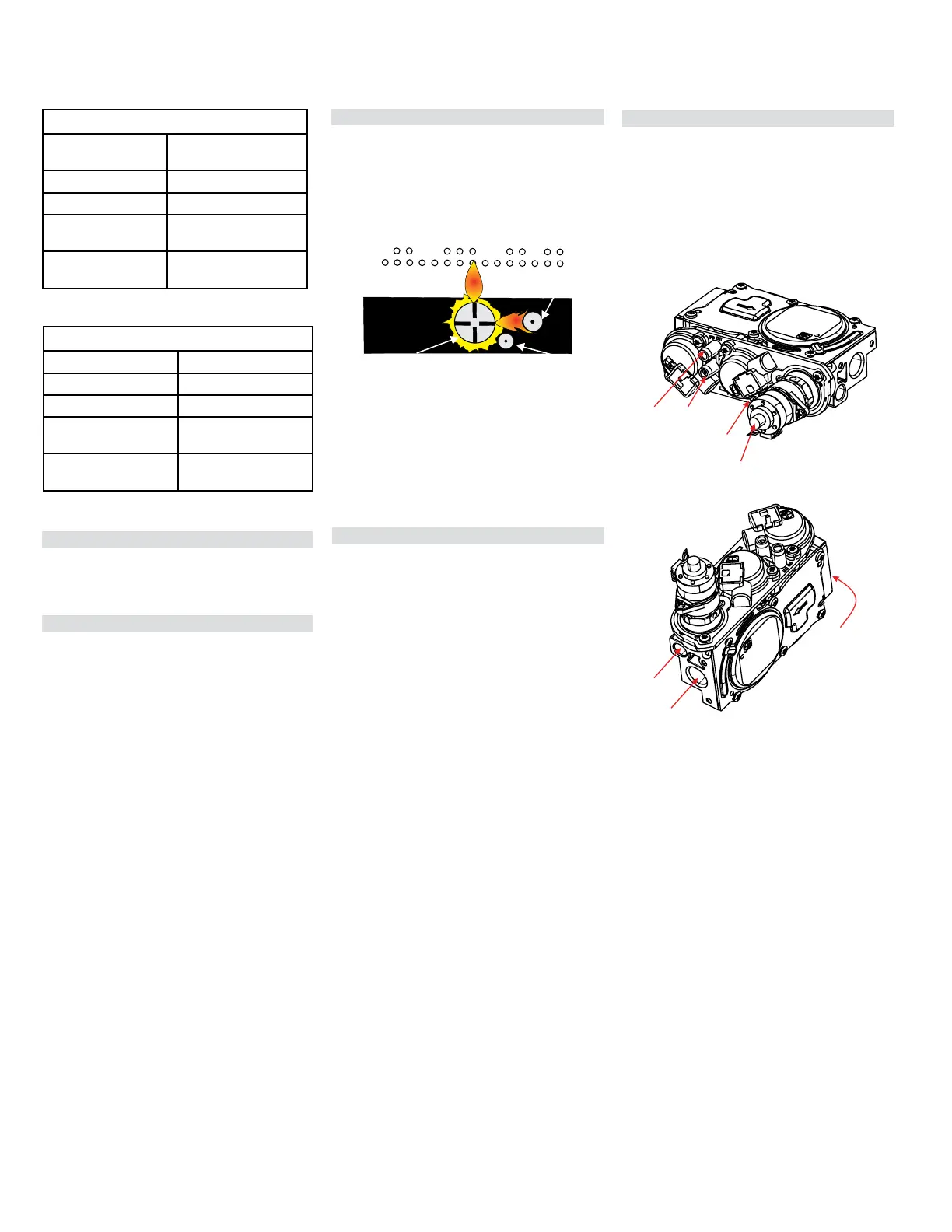

885 S.I.T. Valve Description

1) 6 Stage ame adjustment

2) Pilot adjustment

3) Outlet Pressure Tap

4) Inlet Pressure Tap

5) Pilot Outlet

6) Main Gas Outlet

7) Main Gas Inlet

Loading...

Loading...