Estimating performance factors

If you don’t have a way to directly measure your propulsion system’s electrical

parameters, Dual PowerLab 8x2 enables you to estimate them using before-and-after

flight measurements.

1. Collect data.

a. Charge pack.

b. When charging is finished, record Fuel % and total pack voltage (i.e. sum of cell

voltages).

c. Fly plane (or test on the ground). Record flight time in minutes.

d. Connect pack to charger. Record Fuel % and total pack voltage.

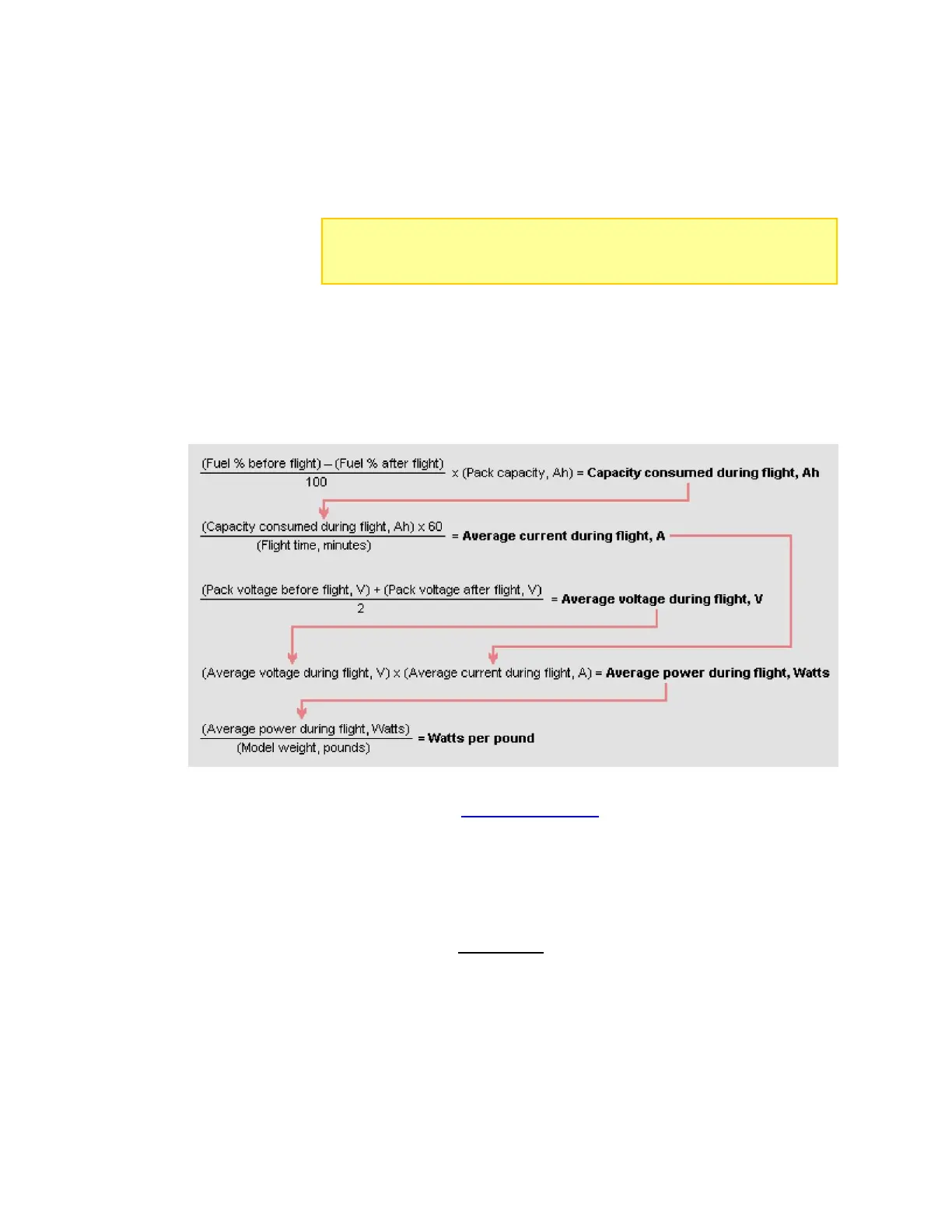

2. Calculate performance factors.

The “LiPo Performance Estimator” spreadsheet can also be downloaded from the

Tech Docs section of the software downloads page of the REVOLECTRIX website.

3. Evaluate results.

Average current during flight gives you a rough idea whether system com-

ponents—ESC, motor, connectors and wiring—are operating within their current

ratings. Keep in mind that peak current during flight may greatly exceed the aver-

age current you calculated.

Watts per pound is an approximate indicator of aircraft performance (other factors

influencing performance include lift, drag and motor type). Here are some guide-

lines:

25 to 30 watts per pound: level flight.

40 to 50 watts per pound: take off from smooth surface, climb.

50 to 75 watts per pound: take off from grass, sport aerobatics.

75 to 125 watts per pound: pattern aerobatics.

Over 125 watts per pound: 3D.

Note: The calculations outlined below work best when the pack is charged

using a custom fuel table. They may be invalid if the fuel table does not match

the pack under test.

Loading...

Loading...