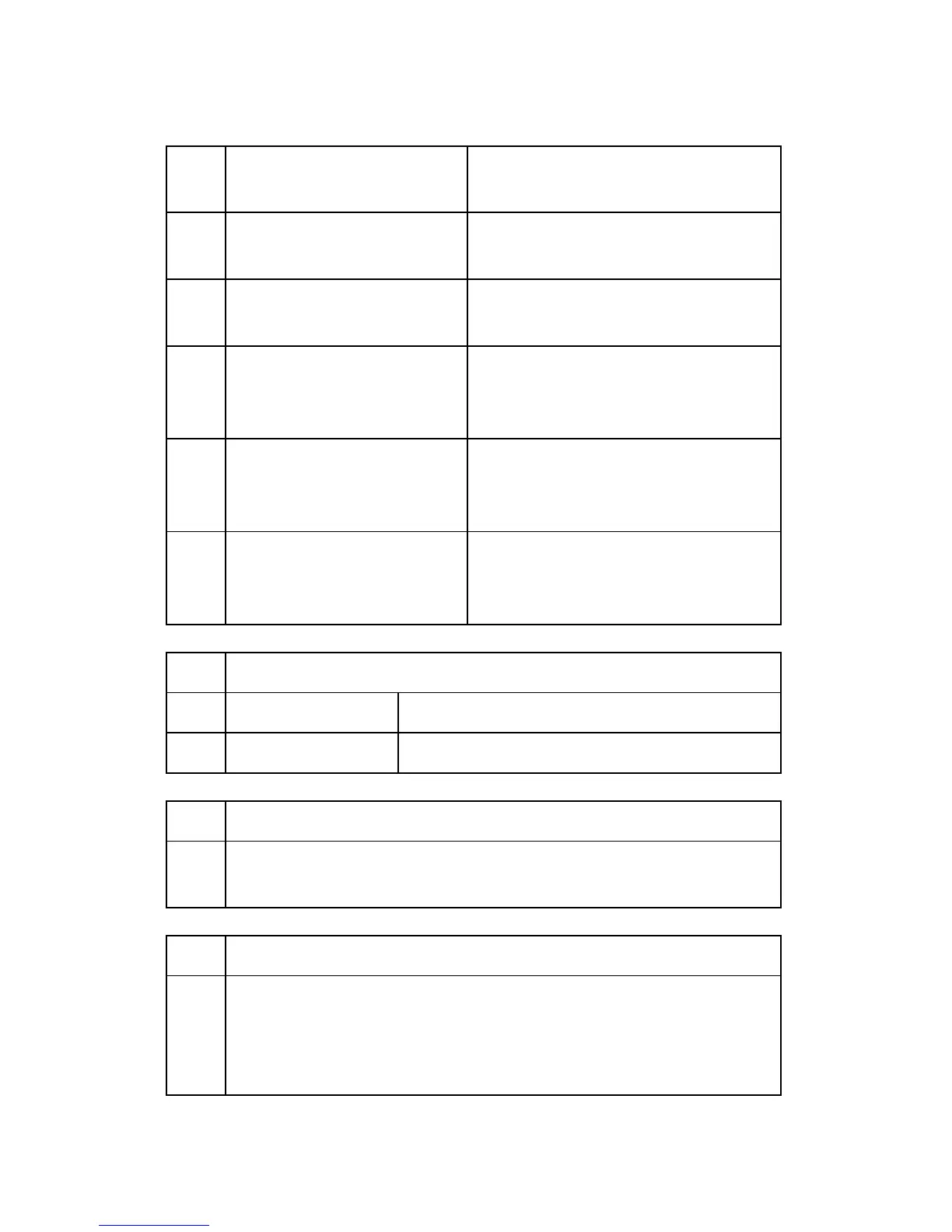

Service Program Mode Tables

D062/D063/D065/D066 4-6 SM Appendix

005

Center Lamp Temp (Small Size

Paper)

D062/D063/D065: [180 to 205/205/1 deg C]

D066: [175 to 190/190/1 deg C]

006

End Lamp Actual Time (Small

Size Paper)

D062/D063/D065: [0 to 120/60/1 sec.]

D066: [0 to 60/10/1 sec]

007 Center Lamp Temp (Thick Paper)

D062/D063/D065: [180 to 205/205/1 deg C]

D066: [175 to 200/200/1 deg C]

008

End Lamp Actual Time (Thick

Paper)

D062: [0 to 120/0/1 sec.]

D063/D065: [0 to 120/5/1 sec.]

D066: [0 to 120/10/1 sec.]

009

Japan only

Capacitator for Check Start

Fusing Temperature

C4c: [170 to 205/200/1 deg C]

010

Japan only

Capacitator for Check Start

Fusing Lamp ON Time

C4c: [0 to 120/0/1 sec.]

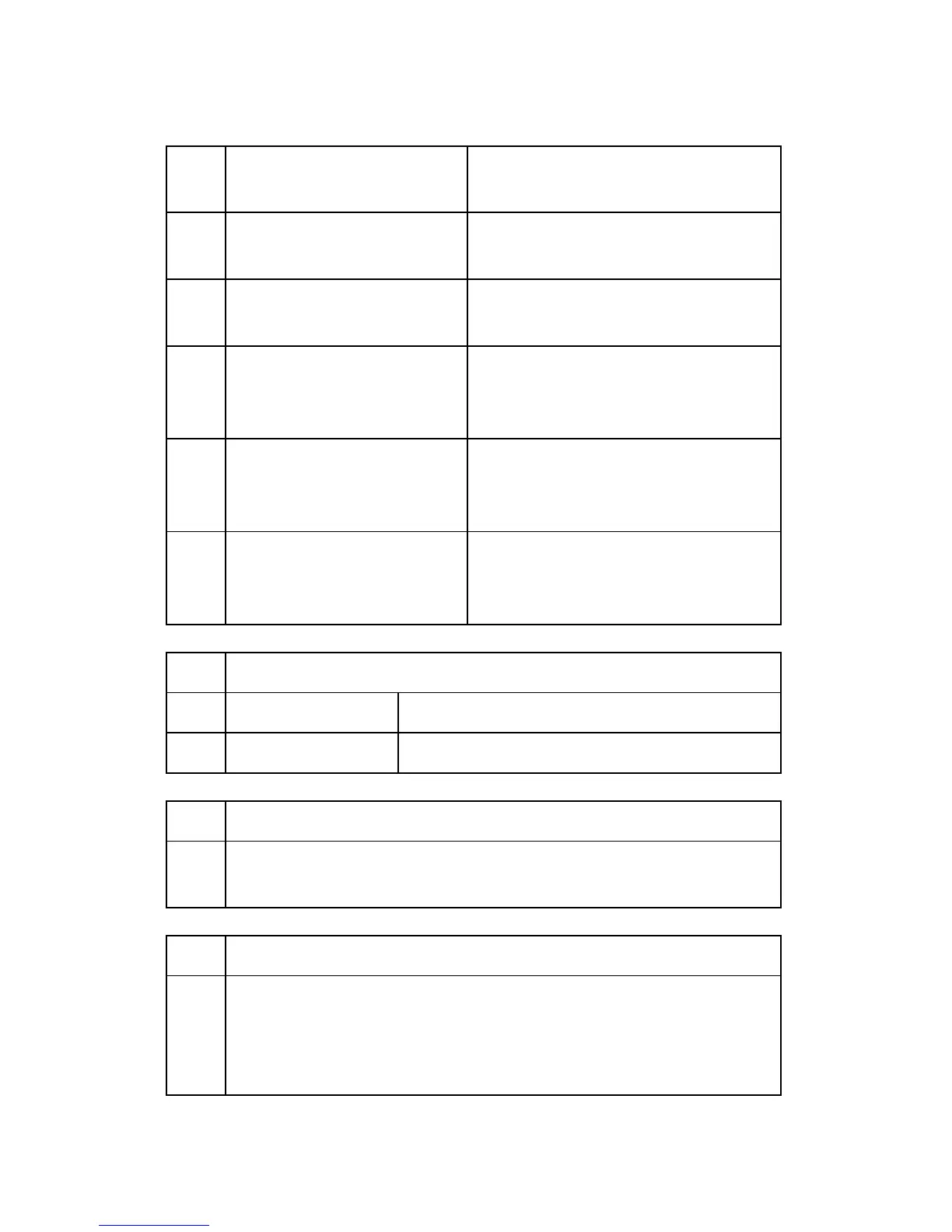

1109 Measure Nip Width

001 Execute 0 or 1

002 Adjust Value

[200 to 400/300/10mm]

1112 Hot Roller Temperature for Auto Process Control

001

Sets the temperature of the hot roller for auto process control to start.

[70 to 150/140/1°C] DFU

1159 Fusing Jam: SC Setting

001

This SP determines what the machine does if paper jams occur in the fusing unit

for three consecutive sheets of paper.

0: (default): A jam alert is shown on the screen. The customer can remove the

jam and the machine works normally after that.

Loading...

Loading...