4.6 Aach the coupling piece to the tube motor

The condions and starng points that follow are applicable.

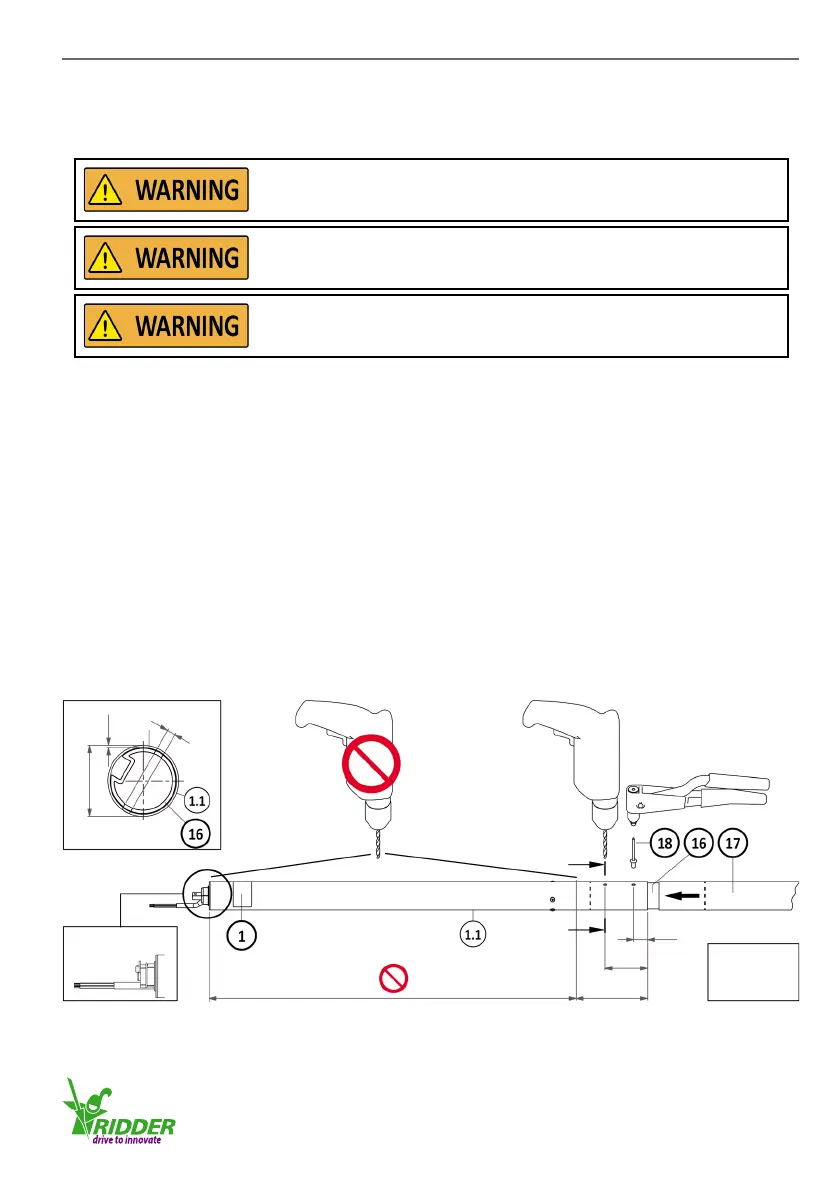

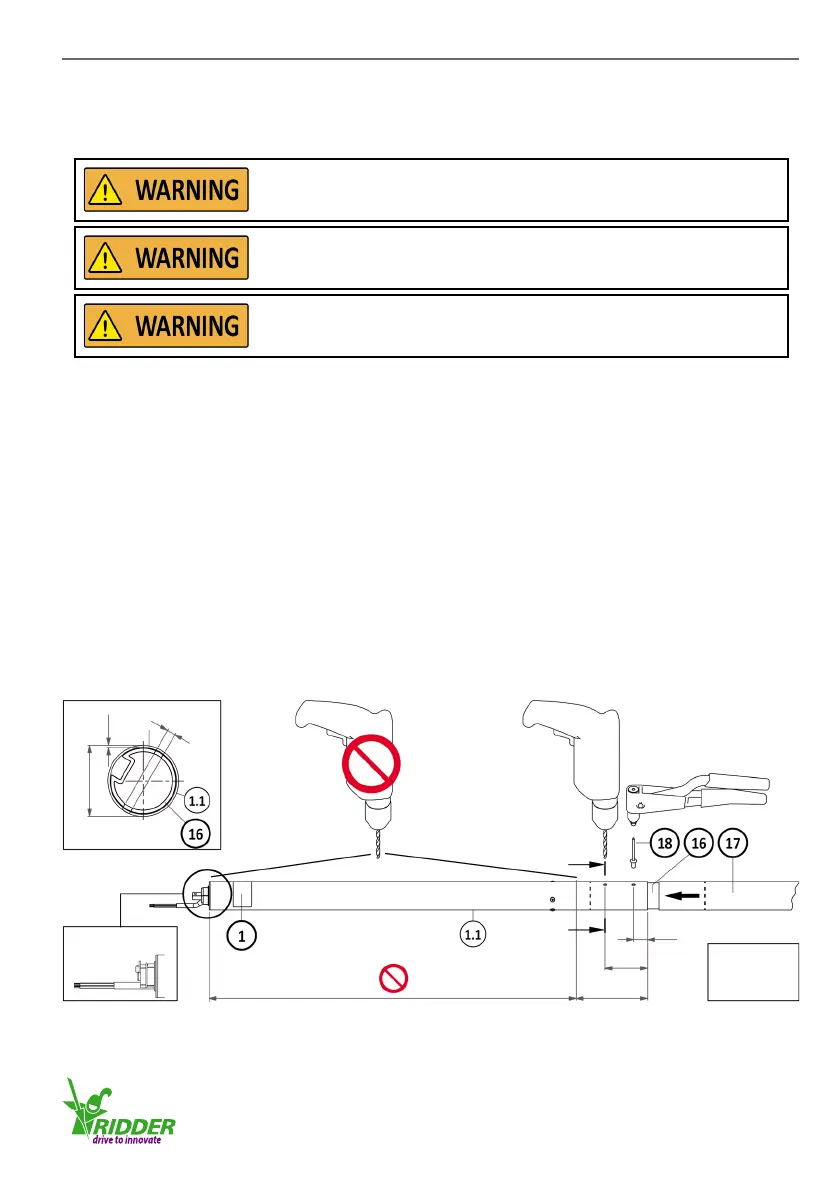

• Use pop-rivets to aach the coupling piece (16) (for a winding tube ø50 mm) to the tube (1.1).

Use a minimum of 4 pop-rivets (18) with a minimum diameter of 5 mm.

Do the procedure that follows.

1. Put the coupling piece (16) into the tube (1.1) of the tube motor (1). Make sure that the distance

into the tube is sucient to drill the holes (d) correctly in the coupling piece (16) and the tubes

(1.1/17). For the four recommended drilling posions (d) refer to illustraons 4.6.1/D-D. Drill

only in the permied part from the open end of the tube (1.1). Note: Drill the holes for the

winding tube (17) in §4.7.

2. Drill one of the holes for the pop-rivets (18) into the tube (1.1) and coupling piece (16)

(minimum of ø5.2 mm if pop-rivets of ø5 mm are used).

3. Use a pop-rivet pliers to aach the pop-rivet (18).

4. Drill the holes for the other three pop-rivets (18).

5. Use the pop-rivet pliers to aach the other three pop-rivets (18).

6. Put the winding tube (17) on the coupling piece (16) at a small distance from the tube motor.

This distance is temporarily necessary when the cord (20.1) is pulled through the winding tube

(17). Refer to step 2 of §4.7.

Do not drill into the tube motor more than 120 mm* from the open

end. *For the tube motor 550039 this is 194 mm.

Make sure that the connecons between the winding tube and the

tube motor are strong enough for the supplied drive torque.

Make sure that the connecons between the winding tube and the

tube motor are aached as smooth as possible.

This is important for the screen cloth.

D-D

d (4x)

50

1.5

25

75

<120*

4.6.1

B

B

550037 (P20)

*550039:

<194 mm

Ridder Drive Systems

T +31 (0)341 416 854 F +31 (0)341 416 611 I www.ridder.com

19

Loading...

Loading...