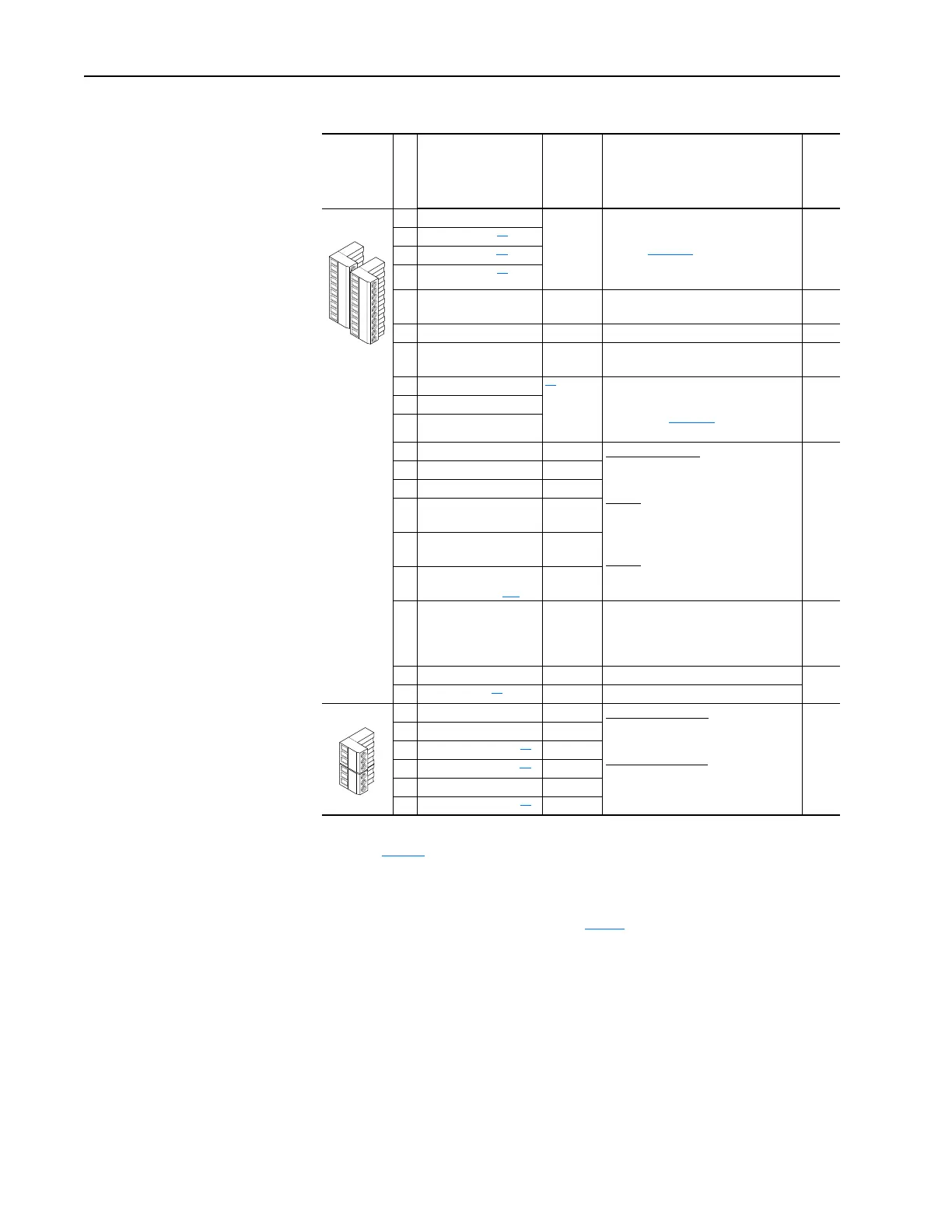

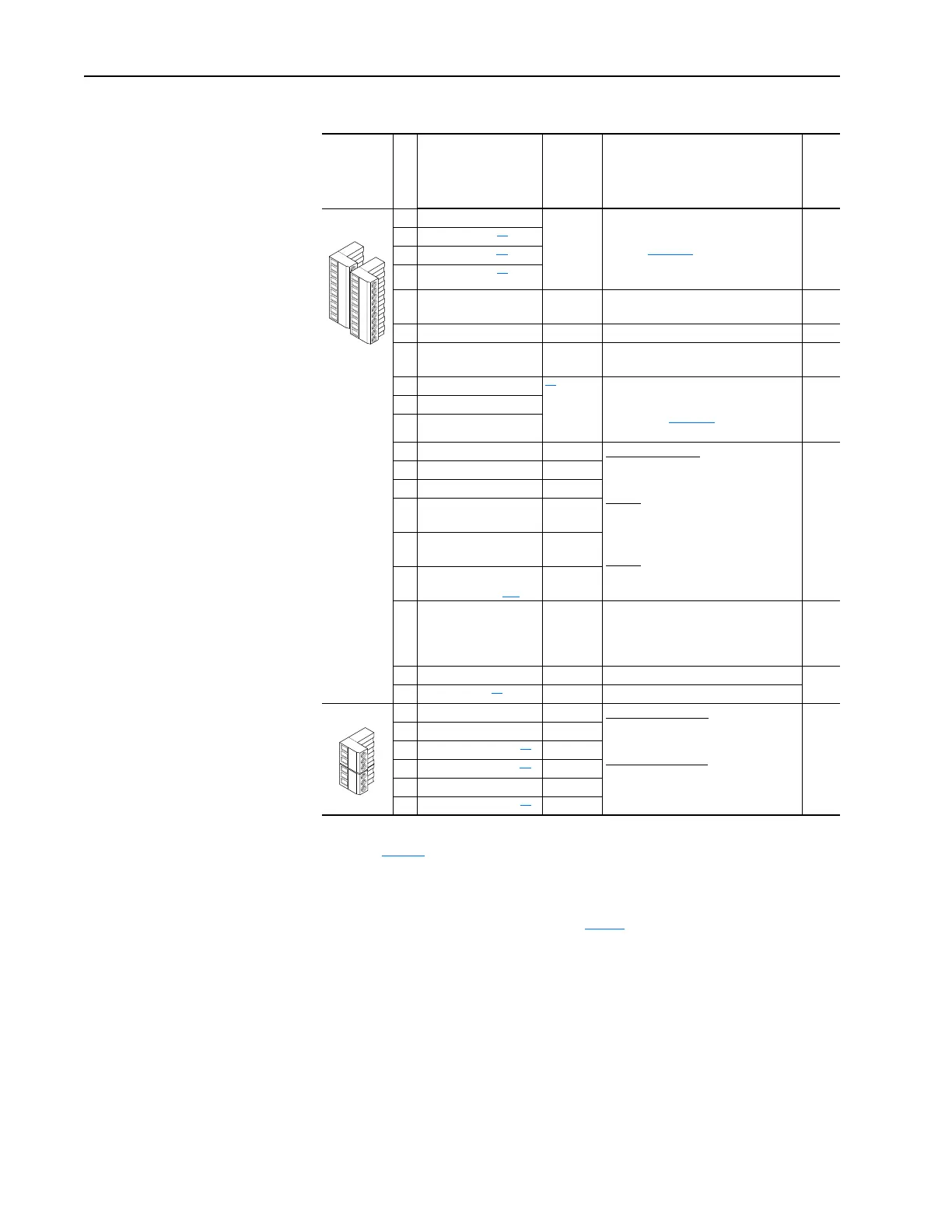

2-4 PowerFlex 700H Control Wiring

Figure 2.2 I/O Terminal Designations

No. Signal

Factory

Default

Description

Related

Parameter(s)

1 Analog In 1 (–)

(1)

(1)

Important: Input must be configured with a jumper. Drive damage may occur if jumper is not installed properly.

Refer to page 2-5

.

(2)

(2)

These inputs/outputs are dependant on a number of parameters (see “Related Parameters”).

Isolated

(3)

, bipolar, differential, 9 bit &

sign, 88k ohm input impedance. A

jumper (page 2-5

) selects: 0-10V,

±10V, 4-20mA. Default: 0-10V (Ri

=200k), 4-20mA (Ri=100 ohm).

(3)

Differential Isolation - External source must be maintained at less than 160V with respect to PE. Input provides

high common mode immunity.

320 -

327

2 Analog In 1 (+)

(1)

3 Analog In 2 (–)

(1)

4 Analog In 2 (+)

(1)

5 –10V Pot Reference – 2k ohm minimum, 10 mA maximum

load, 1% accuracy.

6 Pot Common (GND) For (+) and (–) 10V pot references.

7 +10V Pot Reference – 2k ohm minimum, 10mA maximum

load, 1% accuracy.

8 Analog Out 1 (+)

(2)

Bipolar (current out is not bipolar), 9

bit & sign, 2k ohm minimum load. A

jumper (see page 2-5

) selects: 0-10V,

±10V, 4-20mA.

340 -

347

9 Analog Out Common

10 Analog Out 2 (+)

11 Digital In 1 Stop - CF 115V ac, 50/60 Hz - Opto isolated

Low State: less than 30V ac

High State: greater than 40V ac

24V dc

- Opto isolated (250V)

Low State: less than 5V dc

High State: greater than 20V dc

11.2 mA DC

Enable

: Digital Input 6 is jumper

selectable for HW Enable.

On-Time: < 16.7ms, Off-Time < 1ms

361 -

366

12 Digital In 2 Start

13 Digital In 3 Jog

14 Digital In 4 Speed Sel

1

15 Digital In 5 Speed Sel

2

16 Digital In 6/Hardware

Enable, see pg. 2-5

Speed Sel

3

17

18

Digital In Common Allows source or sink operation.

Terminals 17/18 & 19 can also be

used to provide backup power to DPI

and control devices.

19 +24VDC

(4)

(4)

150mA maximum Load. Not present on 115V versions. Can be used to provide control power from an external

24V source when main power is not applied. Refer to page 2-5

– Drive supplied logic input power.

20 24V Common

(4)

– Common for internal power supply.

21 Digital Out 1 – N.C.

(5)

(5)

Contacts in un-powered state. Any relay programmed as Fault or Alarm will energize (pick up) when power is

applied to drive and de-energize (drop out) when a fault or alarm exists. Relays selected for other functions will

energize only when that condition exists and will de-energize when condition is removed.

Fault Max. Resistive Load:

240V ac/30V dc – 1200VA, 150W

Max. Current: 5A, Min. Load: 10mA

Max. Inductive Load

:

240V ac/30V dc – 840VA, 105W

Max. Current: 3.5A, Min. Load: 10mA

380 -

391

22 Digital Out 1 Common

23 Digital Out 1 – N.O.

(5)

NOT Fault

24 Digital Out 2 – N.C.

(5)

NOT Run

25 Digital Out 2/3 Com.

26 Digital Out 3 – N.O.

(5)

Run

1

10

20

21

Loading...

Loading...