PowerFlex 700H Control Wiring 2-5

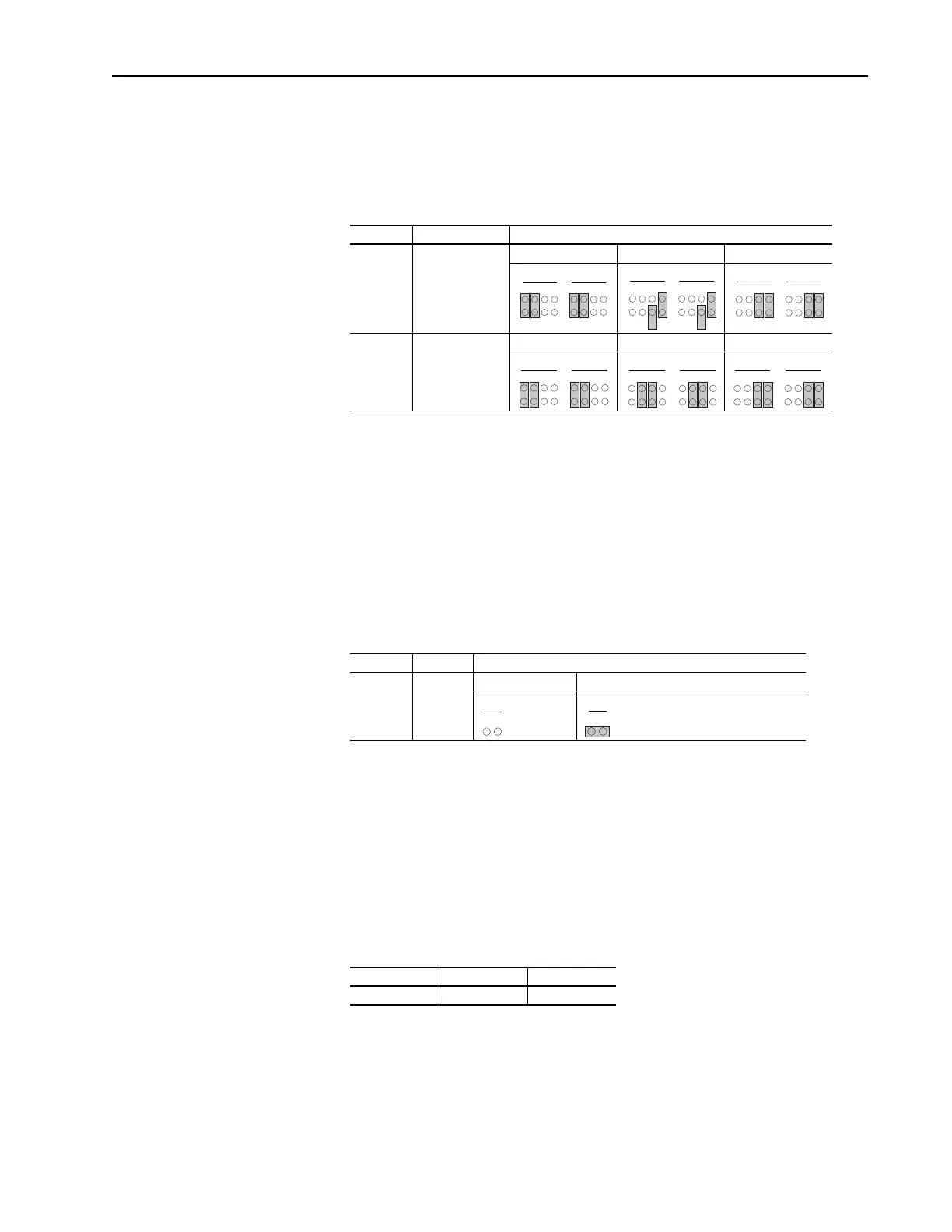

Analog I/O Configuration

Important: Analog I/O must be configured through programming, as well

as the jumpers shown below.

Figure 2.3 I/O Configuration

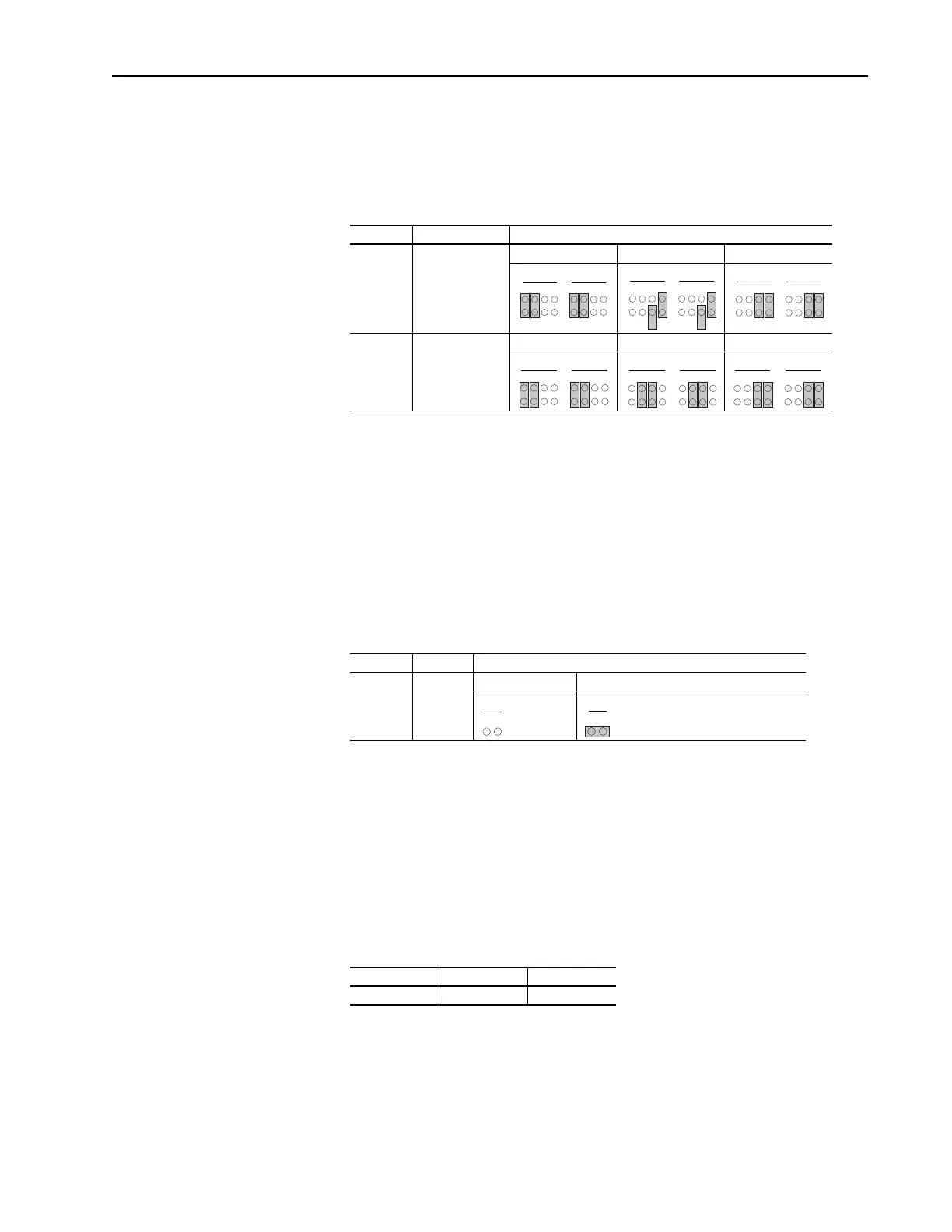

Hardware Enable Circuitry

By default, the user can program a digital input as an Enable input. The

status of this input is interpreted by drive software. If the application

requires the drive to be disabled without software interpretation, a

“dedicated” hardware enable configuration can be utilized. This is done by

removing jumper J5 and wiring the enable input to “Digital In 6” (see

below). Verify that [Digital In6 Sel], parameter 366 is set to “1, Enable.”

Figure 2.4 Hardware Enable Configuration

Auxiliary Power Supply

You may use an auxiliary power supply to keep the 700H Control Unit

energized, when input power is de-energized. This provides back-up power

for the Control Unit and is sufficient for setting parameters. Connect 24V dc

power to pin 19 and 24V dc common to pin 20 of the 24V dc version of the

I/O card.

Auxiliary Power Supply Specifications

Signal Jumper Setting

Analog

Inputs

J1 (Analog In 1)

J2 (Analog In 2)

0-20 mA 0-10V ±10V

Analog

Outputs

J3 (Analog Out 1)

J4 (Analog Out 2)

0-20 mA 0-10V ±10V

Signal Jumper Setting

Hardware

Enable

J5 Hardware Enable Input Programmable (No Hardware Enable)

Voltage Current (Min) Current (Max)

24V dc ± 15% 150 mA 250 mA

CDBA

J1 J2

CDBA

CDBA

J1 J2

CDBA

CDBA

J1 J2

CDBA

CDBA

J3 J4

CDBA

CDBA

J3 J4

CDBA CDBA

J3 J4

CDBA

BA

J5

BA

J5

Loading...

Loading...