2-6 PowerFlex 700H Control Wiring

If 24V terminals of several drives are connected in parallel, we recommend

using a diode circuit to block current flow in the opposite direction. Reverse

current flow could damage the Control Board.

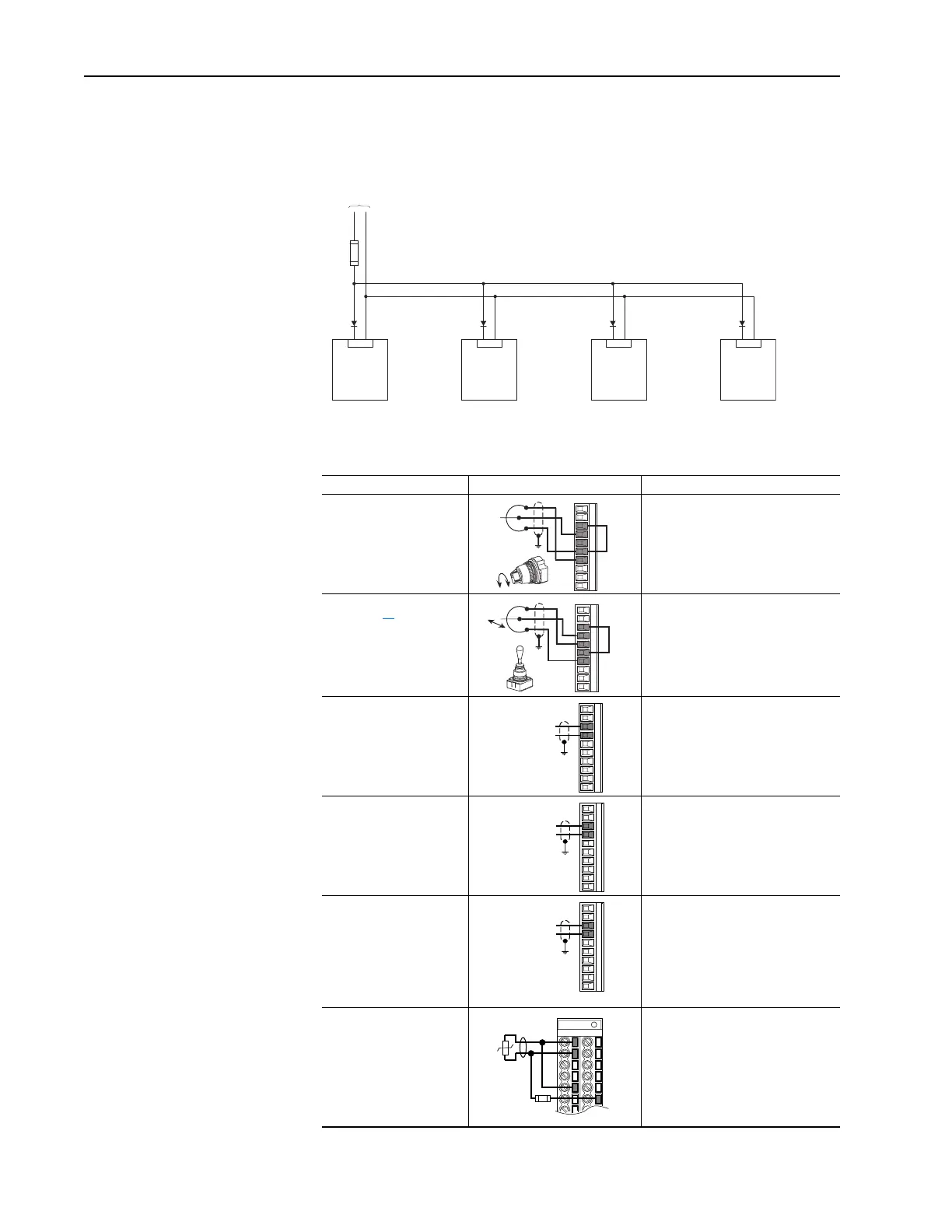

I/O Wiring Examples

Input/Output Connection Example Required Parameter Changes

Potentiometer Unipolar

Speed Reference

(1)

10k Ohm Pot.

Recommended

(2k Ohm Minimum)

• Adjust Scaling:

Parameters 91/92 and 325/326

• View Results:

Parameter 002

Joystick Bipolar Speed

Reference

(1)

±10V Input

• Set Direction Mode:

Parameter 190 = “1, Bipolar”

• Adjust Scaling:

Parameters 91/92 and 325/326

• View Results:

Parameter 002

Analog Input Bipolar

Speed Reference

±10V Input

• Set Direction Mode:

Parameter 190 = “1, Bipolar”

• Adjust Scaling:

Parameters 91/92 and 325/326

• View Results:

Parameter 002

Analog Voltage Input

Unipolar Speed

Reference

0 to +10V Input

• Configure Input with parameter 320

• Adjust Scaling:

Parameters 91/92 and 325/326

• View results:

Parameter 002

Analog Current Input

Unipolar Speed

Reference

4-20 mA Input

• Configure Input for Current:

Parameter 320 and add jumper at

appropriate terminals

• Adjust Scaling:

Parameters 91/92 and 325/326

• View results:

Parameter 002

Analog Input, PTC

PTC OT set > 5V

PTC OT cleared < 4V

PTC Short < 0.2V

• Set Drive Alarm 1:

Parameter 211, bit 11 = “True”

• Set Fault Config 1:

Parameter 238, bit 7 = “Enabled”

• Set Alarm Config 1:

Parameter 259, bit 11 = “Enabled”

:19 :20

From Auxiliary

Power Supply

:19 :20 :19 :20 :19 :20

24V dc

Power

24V dc

Common

3

4

6

6

7

3

6

4

7

5

3

4

3

4

3

4

5

3.32k

Ohm

1.8k

PTC

Ferrite

Bead

1

2

22

Loading...

Loading...