− 127 −

DCUTSIDE

Horizontaland

facingdownward

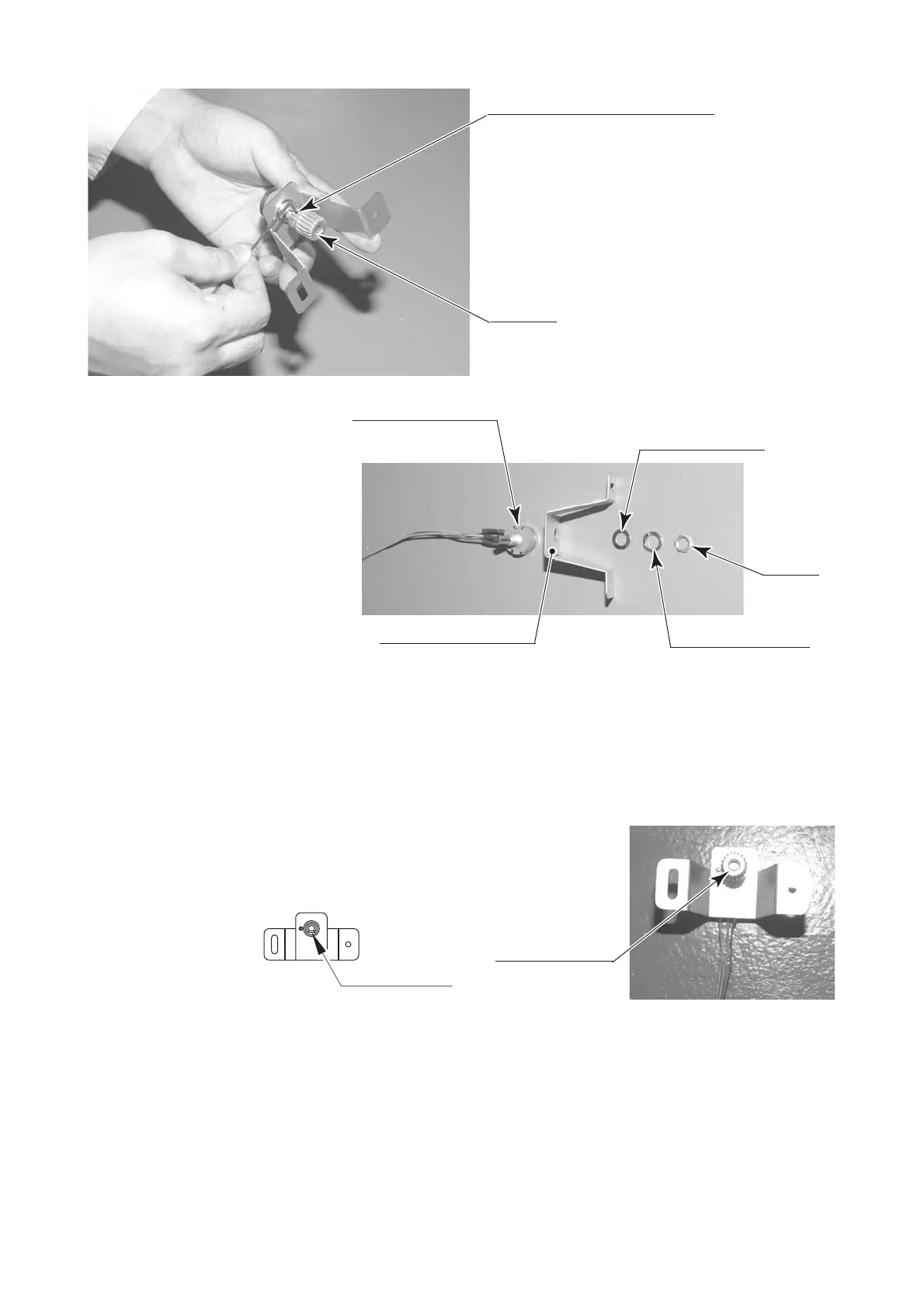

⑥ ThewiresconnectedtotheoldVRcanbereusedforthenewVR.Removetheheatcontraction

tubecoveringthesolderedareas,usethesolderingirontomeltthesolder,andremovethewires

fromtheVR.

⑦ SolderthewirestothenewVR.Checkthewiringdiagramtomakesuretherearenomistakesin

thewiring.Inaddition,useaheatcontractiontubeorotherdevicetopreventshort-circuiting.

⑧ InstallthenewVRandthegearintheRollVRbracket.

⑤Removethenut

securingtherollVR

bracketandthen

removetheVRfrom

thebracket.

⑩ Checktomakesuretheseatislevel.

⑪ InstalltheRollVRunit.InserttheRollVRunitwithoutcausingthegeartorotateandsecureit

with2screws.

Thegearengagementshouldalsobeadjustedatthistime.

⑫ Checktomakesurethe"SEATMOTION"valueontheInputTestscreeniswithintherange

80H ± 8Hwhentheseatislevel.Ifthevalueisoutsidethisrange,adjusttheVRagain.

NUT

SPRINGWASHER

FLATWASHER

ROLLVRBRACKET

VR

220-5484、220-5753

PHOTO12.2e

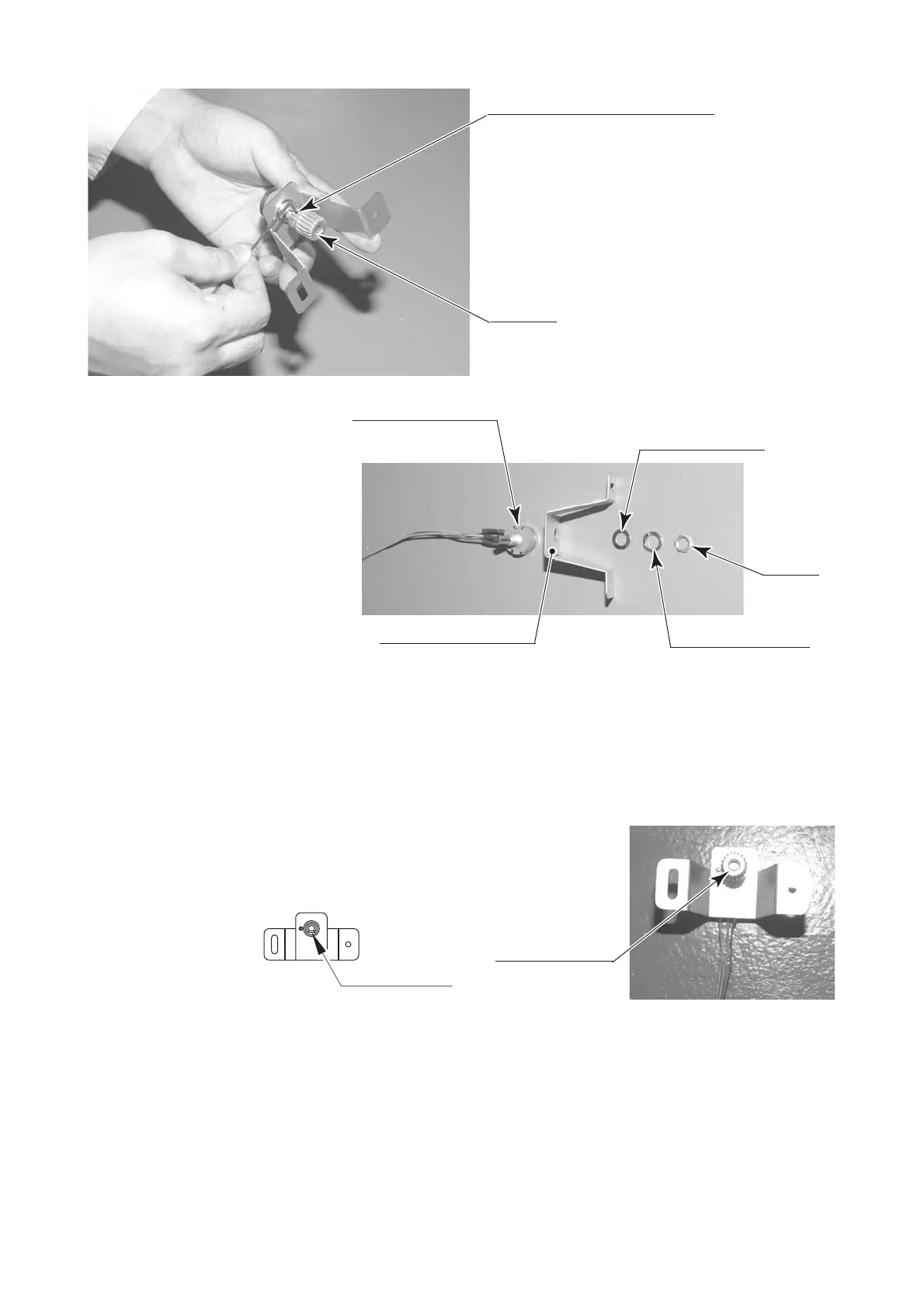

⑨ RotatethegearsothattheD-cutsideoftheVRaxleis

horizontalandfacingdownward.

PHOTO12.2f

DCUTSIDE

Horizontaland

facingdownward

④Loosenthe2hexagonsocketscrews

holdingthegearinplaceandremovethe

gearfromtheVRaxle.

PHOTO12.2d

GEAR

FIG.12.2

HEXAGONSOCKETSCREW(2)

M3×6

Loading...

Loading...