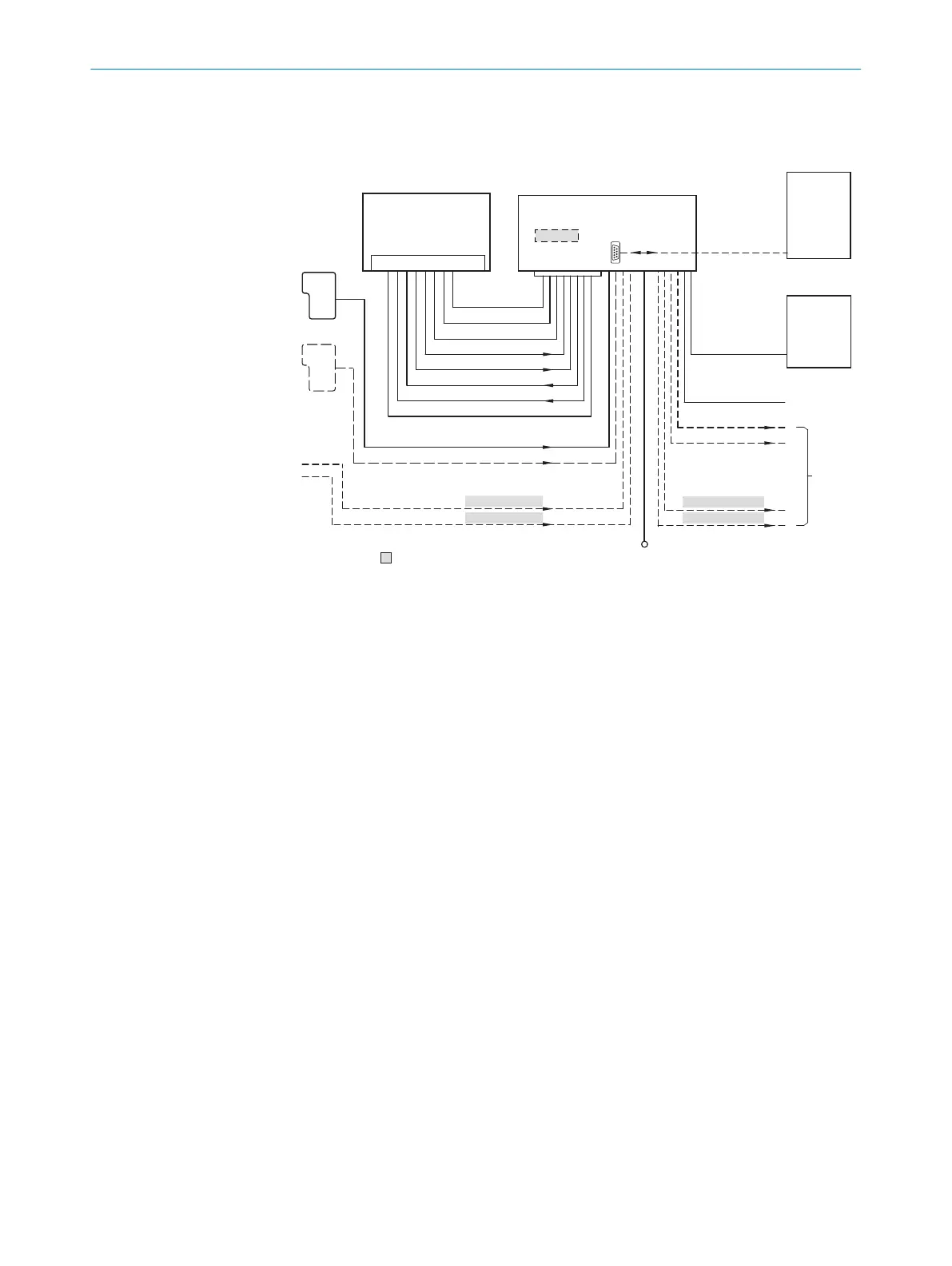

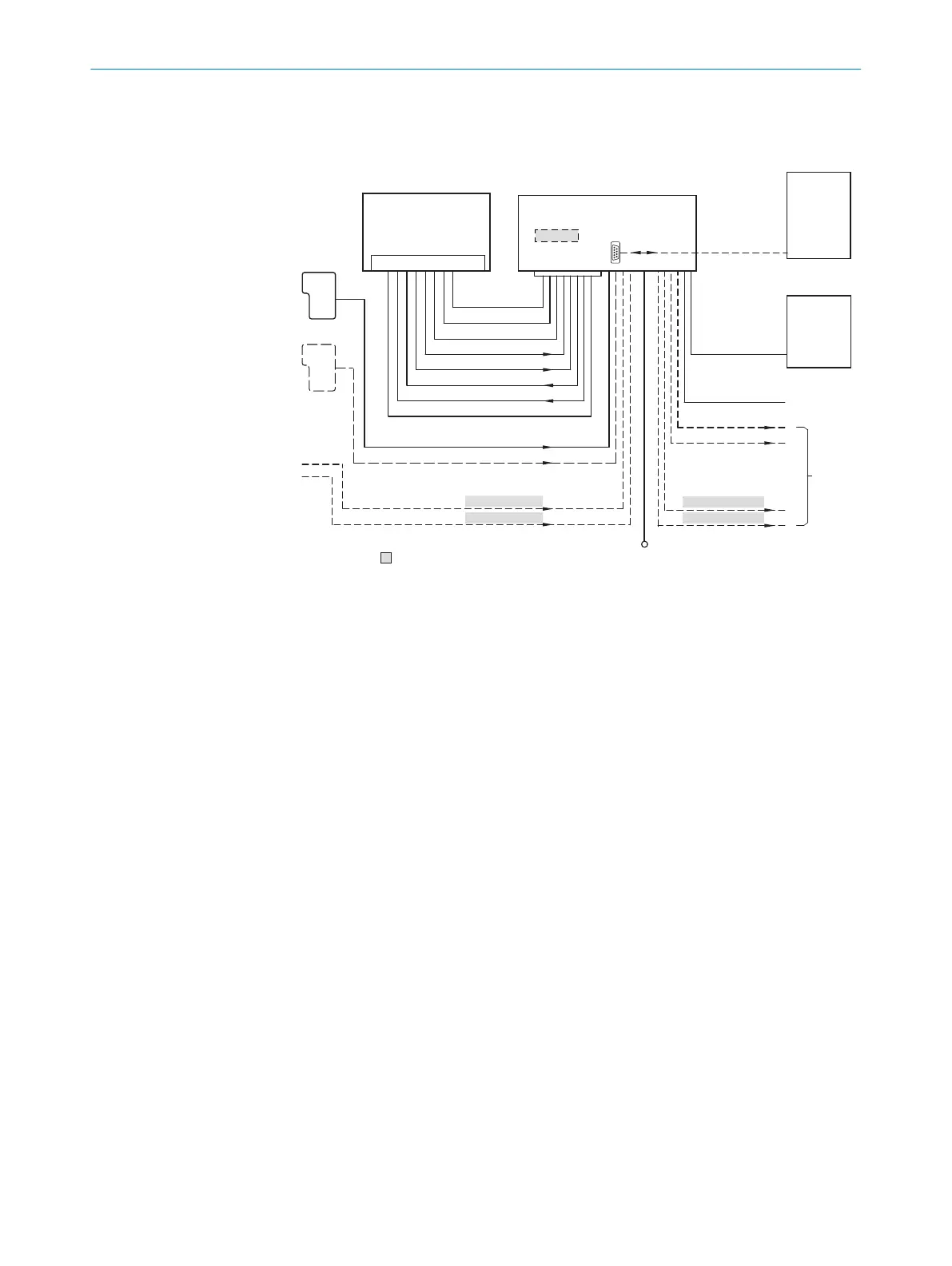

6.4 Connection diagrams

“V

S

”

“Host”

“Aux”

“Result 2”

“Result 1”

“CAN” 3

“Sensor 2”

“Sensor 1”

“AUX”

CAN bus 3

“Result 1”

“Result 2”

PLC

CDB620/ CDM420 !

Connection module 4

“Host”

“Aux 1”

RS-232

HOST/PLC

Further data

processing 6

Computer

Configuration

Diagnostics 5

Interfaces 2

RS-232

“Sensor 2”

“Sensor 1”

“External input 2”

“External input 1”

CMC600

â

á

à

V

S

8

= ß

“External output 2”

“External output 1”

Device 1

9 7

!

CDB620-001 or CDM420

1

Device

2

Interfaces

3

CAN

4

Connection modules

5

Configuration or diagnostics

6

Data further processing

7

External digital outputs

8

Supply voltage V

S

9

External digital inputs

ß

The CM600 parameter cloning module is required in the connection module in order to be

able to use the additional external digital inputs and outputs of the device (highlighted in

gray)

à

Other functions

á

Application-specific alternative stop reading pulse (e.g., photoelectric sensor) or travel

increment (incremental encoder)

â

Start/Stop reading pulse (e.g., photoelectric sensor)

6.5 Wiring interfaces

6.5.1 Connecting the supply voltage

Connect the device only to a power supply unit that has the following properties:

•

Stabilized safety extra-low voltage SELV according to currently valid standards

•

Supply voltage, depending on the length of the connecting cable:

°

10 V DC to 30 V DC, for devices with connecting cable 0.6 m up to max. 3 m

°

12 V DC up to 30 V DC, for devices with connecting cable 3 m up to max. 6 m

6 ELECTRICAL INSTALLATION

40

O P E R A T I N G I N S T R U C T I O N S | CLV61x 8017840/19OF/2021-10-28 | SICK

Subject to change without notice

Loading...

Loading...