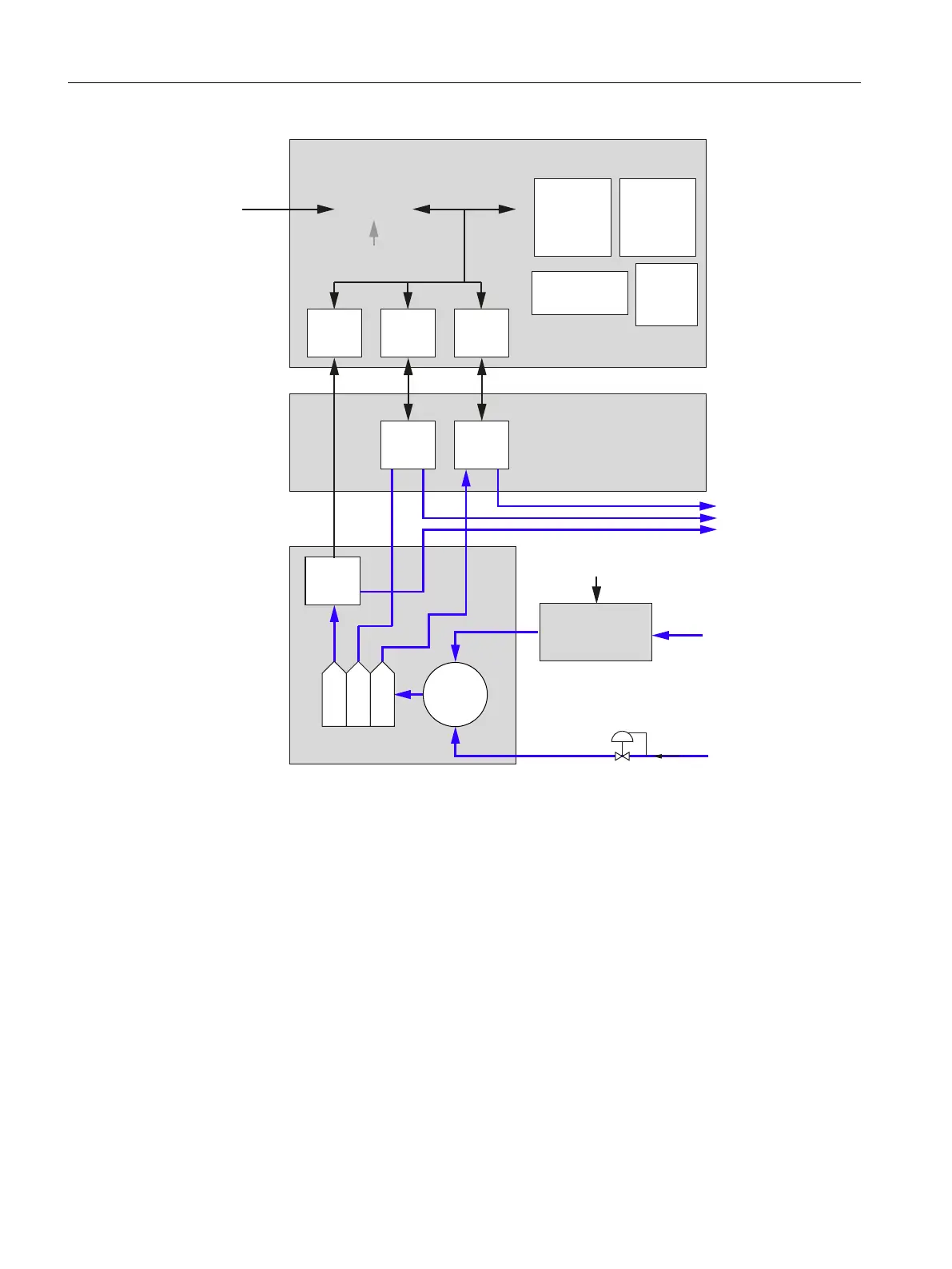

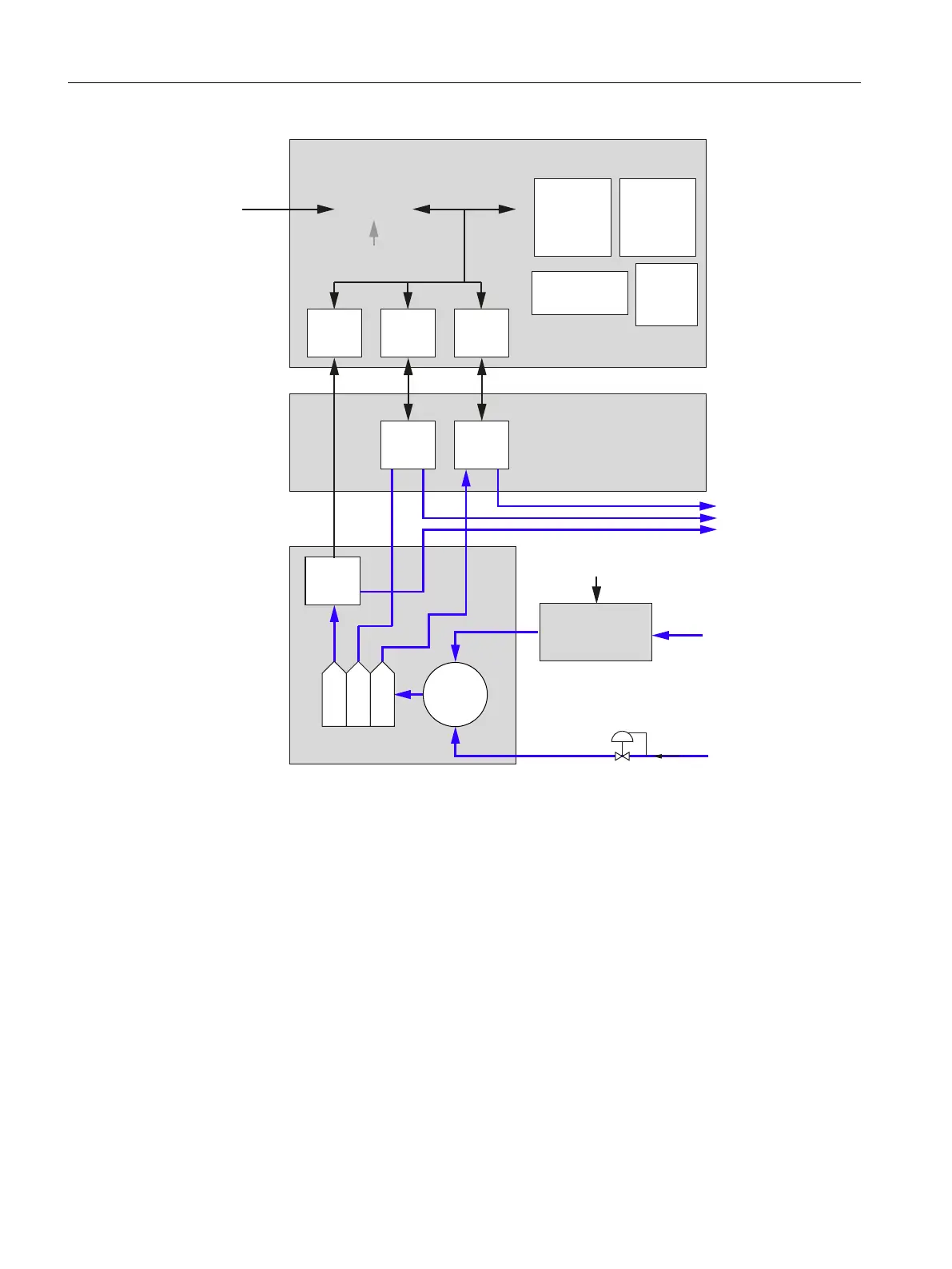

FPD

DPM

(A/D)

SYSCON

SNE Software Moule

GCP

I

2

C

Network

DPM

(A/D)

Electronic

Pressure

Control

Module

Solenoid

Valve

Control

Module

Temperature

Control

Oven

Heater

Control

Electronics Enclosure

DPM

(A/D)

FID

Detector Compartment

(Mezannine)

Oven

Sample

Conditioning

Atmosphere Vents

Feedthroughs

Sample In

TCD

Columns

Sample

Valve

Columns

Columns

Regulated Carrier Gas

I

2

C from SYSCON

Figure 3-2 Operational Block Diagram (Maxum II Airless Airbath model shown)

Power On

The Power Entry Control Module (PECM), in response to commands on internal bus, accepts

system primary power and provides switching and control of AC power for oven heaters and

other AC powered devices.

Sample Conditioning

Before being piped to the analyzer, the sample from the process is sent to a sample conditioner

system. The sample conditioner ensures that the process sample is compatible with the

requirements of the analyzer. That is, it assures that the phase, pressure, temperature and

flow rate to the analyzer are suitable, that the sample is filtered, that condensates are removed

and other treatments are carried out. The resultant conditioned sample is typically piped via

1/8-inch stainless steel tubing to the sample valve(s) located in the oven of the Maxum II.

System Functions

3.3 Analyzer Operation

Maxum edition II Analyzer General Maintenance

14 Manual, August 2018, A5E42019842001

Loading...

Loading...