4.6.15 Alarms 3117 - 3204 EPC

GCP Alarm Descriptions 3117 - 3204 EPC

The following tables list the alarm number (#), type (+ information, ? warning, ! error) alarm

text, description, and actions.

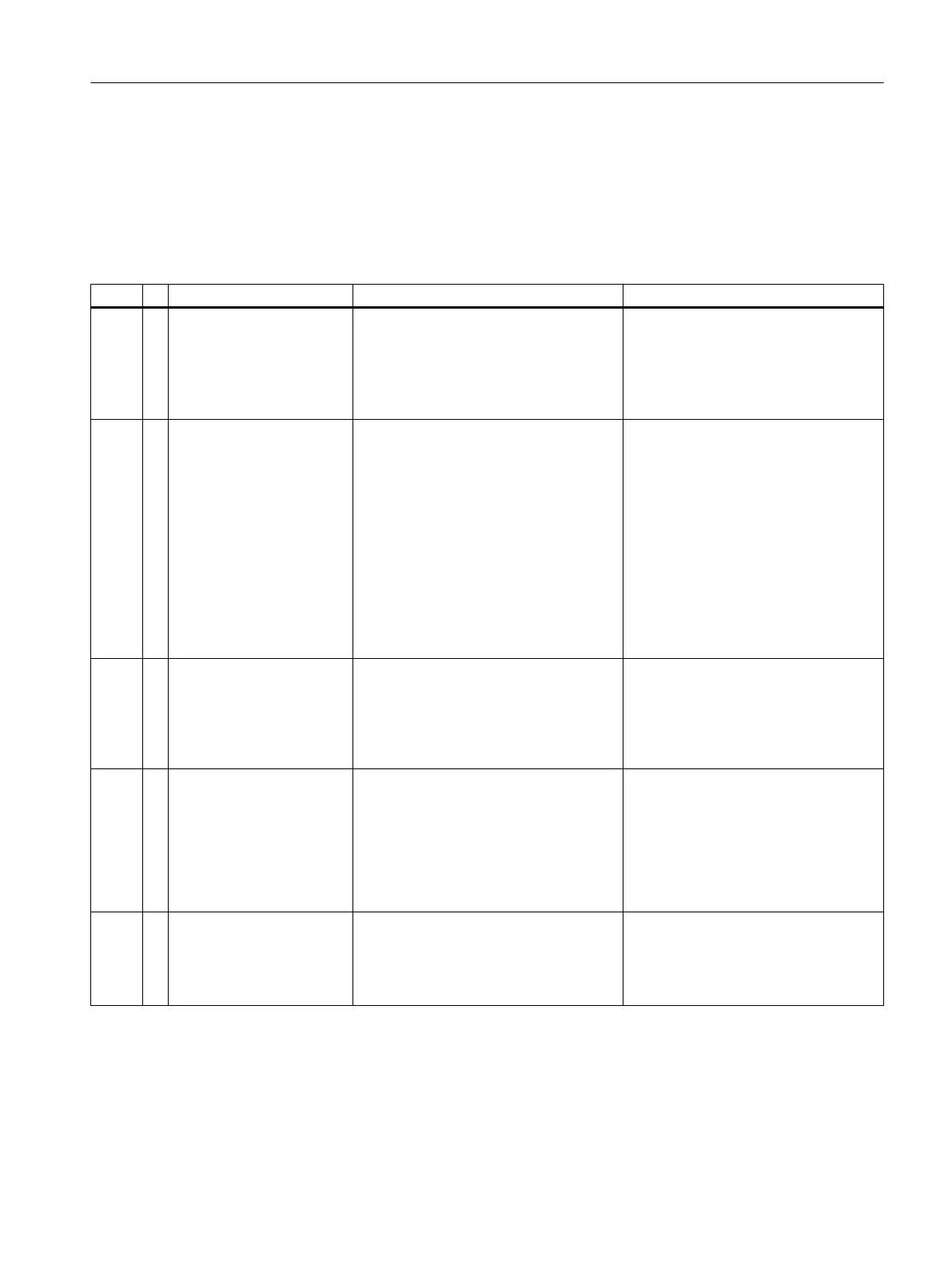

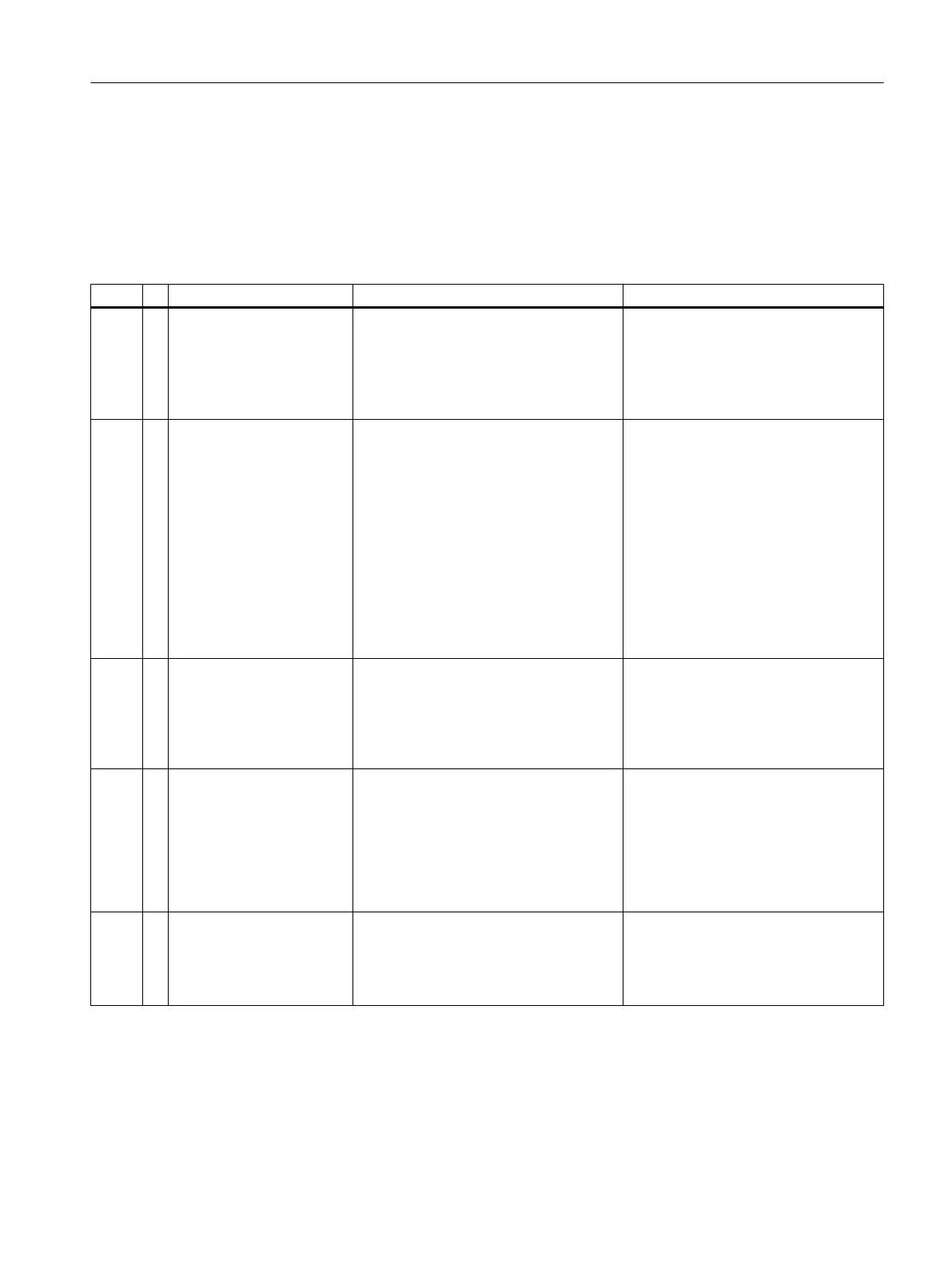

# Text Description Action

3117,

3118

! Pressure [1 - 2] Out-Of-

Control on %4

EPC (Electronic Pressure Controller)

PIC: The measured pressure, on chan‐

nel #n, has exceeded the absolute maxi‐

mum allowed pressure and the corre‐

sponding channel was shutdown. The

pressure controller is no longer working.

Confirm that the flow is greater than the

minimum specification. Replace the

EPC.

3119,

3120

! A/D [1 - 2] Failure on %4 EPC (Electronic Pressure Controller)

PIC: The Analog to Digital Converter chip

does not work properly. The flag will be

set if the A/D internal calibration cycle is

not completed within a pre-determined

period of time or the A/D does not report

any valid data within a pre-defined time‐

out period.

Note: A firmware problem affecting the

version 0.250 of the EPC PIC may cause

an A/D failure flag to show-up occasion‐

ally following a PIC reset. This is not a

sign of a defective A/D converter.

Cycle power. If the error repeats con‐

sistently, replace the module.

3157,

3158

? Low Supply Pressure [1 - 2]

on %4

EPC (Electronic Pressure Controller)

PIC: Set when the contact on the optional

supply pressure sensor on [J5 or J6] is

closed indicating that the supply pres‐

sure is getting low and that the bottle

must be changed soon.

Check air supply. Replace supply bottle.

3159,

3160

! Deviation [1 - 2] Exceeded

on %4

EPC (Electronic Pressure Controller)

PIC: The measured pressure deviation

has exceeded the corresponding

MAX_DEVIATION value. The PID con‐

trol was not successful in controlling the

pressure with the desired precision on

channel #n.

MAX_DEVIATION_x that is too small.

An improper setting of TIME_LIM‐

IT_DEVIATION_UP_x or TIME_LIM‐

IT_DEVIATION_DN_x.

Insufficient supply pressure.

Flow too small or too large.

Defective EPC.

3161,

3162

? Setpoint [1 - 2] changed fol‐

lowing a change in Max

Pressure

EPC (Electronic Pressure Controller)

PIC: The SETPOINT_[n] AO value was

modified internally as a result of the SET‐

POINT_MAX_[n] AO value set to a value

lower than the SETPOINT_[n] value.

Set the SETPOINT_MAX_[n] value first

and then set the setpoint.

General Maintenance and Troubleshooting

4.6 Alarm Codes, Descriptions, and Suggested Actions

Maxum edition II Analyzer General Maintenance

Manual, August 2018, A5E42019842001 69

Loading...

Loading...