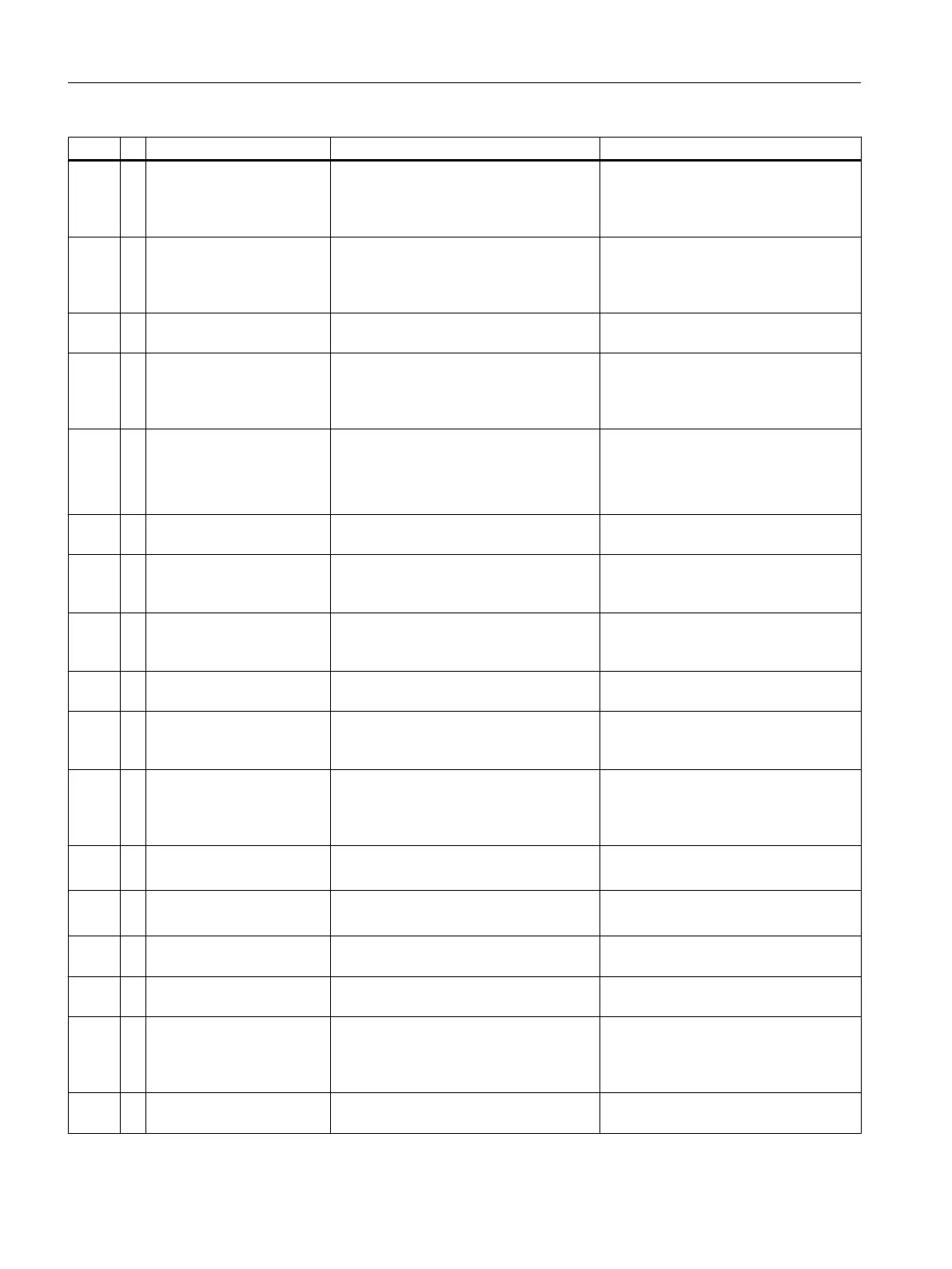

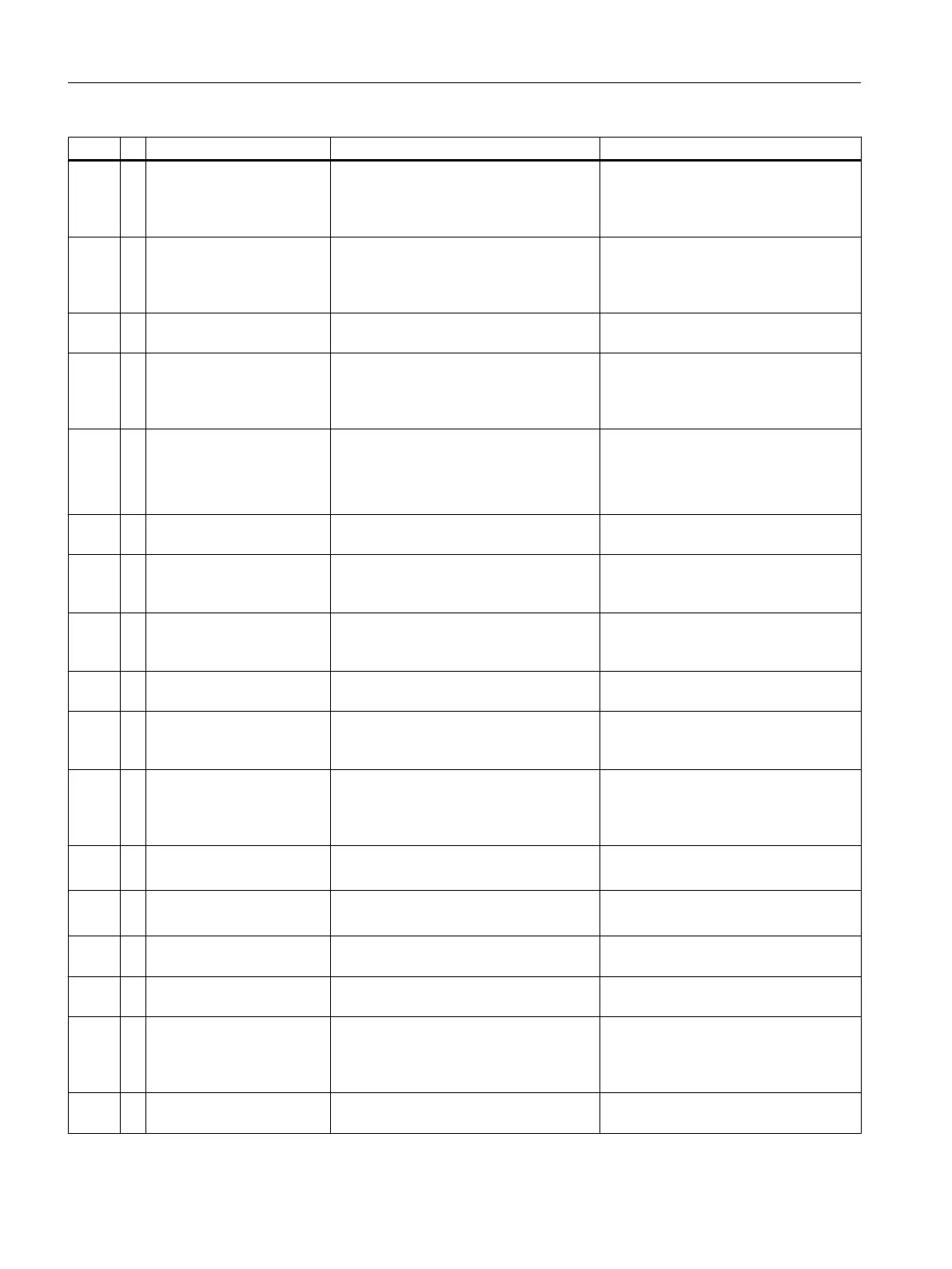

# Text Description Action

371 ! Invalid channel acquisition

overlap on %3

Two channels referencing the same

hardware detector are scheduled to ac‐

quire at the same time.

If multiple application detector channels

are assigned to the same hardware de‐

tector, do not allow their times to over‐

lap.

372 ! Scheduling error %3 scan‐

ning %4 # %5 channel %6

Unable to schedule all event and polling

routines. May indicate a memory or hard‐

ware failure.

If method schedules many events as

well as all 18 detectors, try removing

some of the events or deleting some of

the detectors, then resetting the SNE.

373 ! Module I/O error %3 on %4

# %5 channel %6

Error between module and channel. Indi‐

cates obsolete anayler.

Consider upgrading analyzer.

374 ! Internal communication er‐

ror %3

Software modules inside SNE are failing

to communicate. Usually happens with

out of memory condition resulting from

SYSCON timeout.

Reduce processing requirements on

SYSCON.

375 ! End of cycle missed; stop‐

ping cycle

The message that coordinates the end of

a method around the SNE tasks was lost.

Reset SNE.

Reduce the complexity of the SNE set‐

up.

Replace SNE.

376 + Adjusting cycle clock mas‐

ter

Obsolete software version. Contact Customer Support.

377 ! Error %3 scheduling cycle

clock master adjustment

Resource not found for scheduling ad‐

justment of event clock. SNE may be

overloaded.

Reduce complexity of tasks for

SNE.Reset SNE to prevent event clock

overflow.

378 + %3 samples adjusted on

chrom from channel %4

An excessive number of samples re‐

quired adjustment on chromatogram. Oc‐

curs in conjunction with DPM alarms.

Replace affected DPM.

379 ! Error %3 preparing analy‐

sis for channel %4

EZChrom processing error. Check integration events; modify

events that may cause problems.

380 ! Error %3 finding chrom

peaks for channel %4

EZChrom processing error. Check integration events and peak ta‐

ble; modify events that may cause prob‐

lems.

381 ! Error %3 generating re‐

sults for channel %4

EZChrom processing error. Example er‐

ror: Setting the threshold value too low,

causing many peaks to be detected in

the noise of the chromatogram.

Check method for problems that could

affect results.

382 ! EZChrom server failed er‐

ror %3 on channel %4

Resource problem on SNE. Reduce SNE workload.

Replace SNE.

383 ? Software Watchdog Time‐

out

SNE is running out of processing capaci‐

ty.

Reduce SNE workload.

Replace SNE.

384 ! Method Modification Failed An attempt to modify a running method

failed, most likely due to invalid data.

Verify that modification was valid.

385 ? Event occurred before

modification request

Before a modification of a running meth‐

od was completed, the event occurred.

Contact Customer Support.

386 ! Invalid Cycle Length %3 A cycle length larger than the maximum

size was specified in a method. Usually

caused by a corrupt method. Maximum

cycle length is approximately 2 days.

Verify correct values in method.

387 ! Invalid Sample Rate %3 on

channel %4

Invalid sample rate value chosen for

channel in method.

Verify the methods and use only a sup‐

ported detector sample rate.

General Maintenance and Troubleshooting

4.6 Alarm Codes, Descriptions, and Suggested Actions

Maxum edition II Analyzer General Maintenance

36 Manual, August 2018, A5E42019842001

Loading...

Loading...