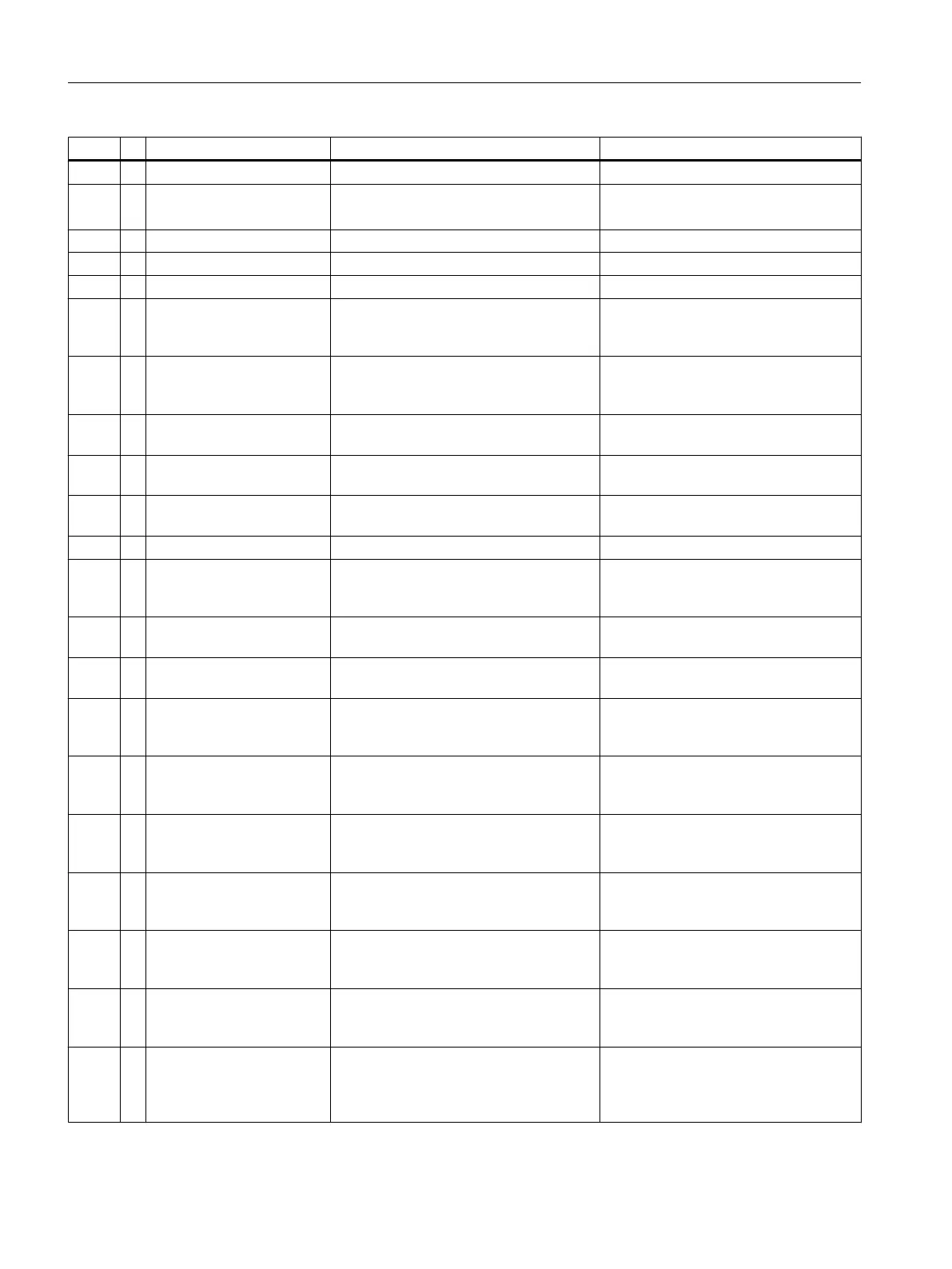

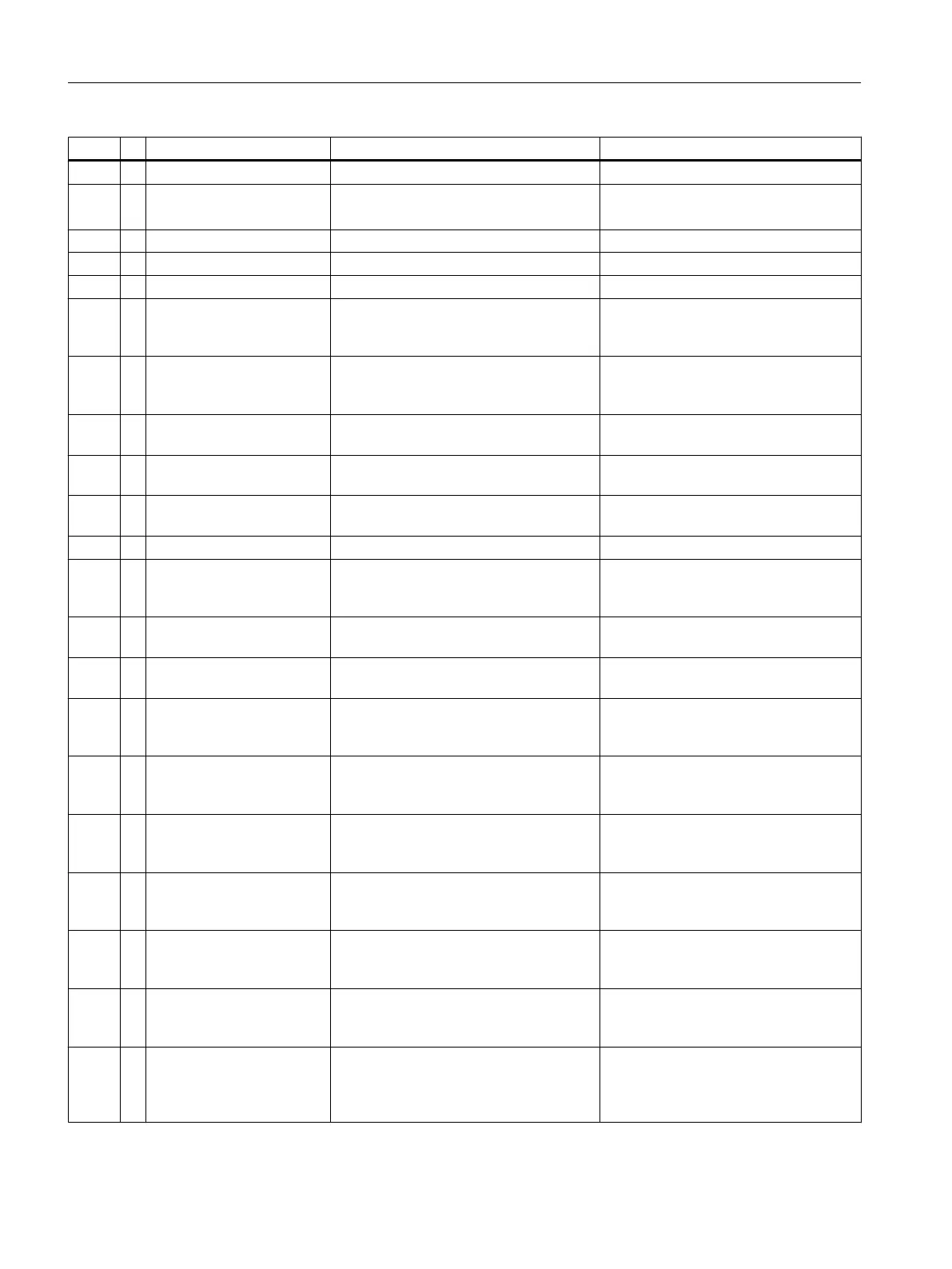

# Text Description Action

711 + Database: %3 System error Contact Customer Support.

712 ! %6 Start Ver: %3 - %4 on

%5

SYSCON has been reset.

Informational message.

No action necessary.

713 + System backed up System error Contact Customer Support.

714 + All alarms cleared System error Contact Customer Support.

715 + Database Build System error Contact Customer Support.

716 ? DB: Invalid Sourcekey or

SourceAttribute for Stat‐

Mon table: ID %3

Occurs when StatMon table is not prop‐

erly configured.

Consult documentation.

717 ? DB: Calibration : margin

check/reports are invalid

for curve type

Occurs when a margin is set in EZChrom

for a curve type that does not support

margin checking.

Remove margin or change curve type.

718 ? Validation failed for %3 Validation has failed. Check report or validation results

screen on the HMI or CIM Display.

719 + Database: SNE reset re‐

quested

SNE is indicating that it has been reset

from a database request.

May indicate a communication over‐

load.

720 ? Database: Reprocess dur‐

ing Run not allowed

Reprocess button pushed while applica‐

tion in run.

Only push reprocess button when ap‐

plication is in hold.

721 + Application is in service Informational message. No action is necessary.

722 ? Reference Component not

found; Component %3 ,

Reference %4

Quantra alarm. Contact Customer Support

723 ! Database: Method ID %3

not found

Method ID is in sequence, but not in

method table.

Check method table.

724 ? Calibration or Validation

failed; application in hold

Calibration or validation was requested

while one was already running.

Check timing of calibration or validation

events.

725 ? DB: Method %3 halted Application was halted from the HMI,

CIM display, or a MaxBasic program. In‐

formational message.

No action necessary.

726 ! DB: Slave application

stream is invalid %3

A stream ID in slave does not line up with

master application stream ID (new re‐

quirement for version 4.0).

Check master and slave sequences.

727 ? DB: Master app autocali‐

bration completed before

Slave app %3

Master autocalibration sequence is fin‐

ishing before slave autocalibration.

Check length of sequences. Master au‐

tocalibration sequence must finish after

slave autocalibration.

728 ? DB: application cannot au‐

tocalibrate

Autocalibration was requested on appli‐

cation that is not defined for autocalibra‐

tion.

Check autocal attribute in application

table.

729 ! DB: message processing

timeout for message %3;

attempting recovery

System error Contact Customer Support.

730 ! DB: Unnamed peak pro‐

cessing exceeded (2000)

for channel %3

Processing for unnamed peaks must not

exceed 2000 peaks for a channel. Ex‐

cess peaks were discarded.

Increase the EZChrom threshold value

to reduce the number of peaks.

731 ! CAN initialization failure for

application %3

Application does not start until CAN

cards required by the application are ini‐

tialized. The application starts regardless

of the error after 30 seconds.

Verify that all application I/Os are prop‐

erly initialized. Remove any I/O that de‐

pends on a CAN card that is not present.

General Maintenance and Troubleshooting

4.6 Alarm Codes, Descriptions, and Suggested Actions

Maxum edition II Analyzer General Maintenance

44 Manual, August 2018, A5E42019842001

Loading...

Loading...