6 Troubleshooting International English

MICROMASTER 440 Operating instructions

70 6SE6400-5CA00-0BP0

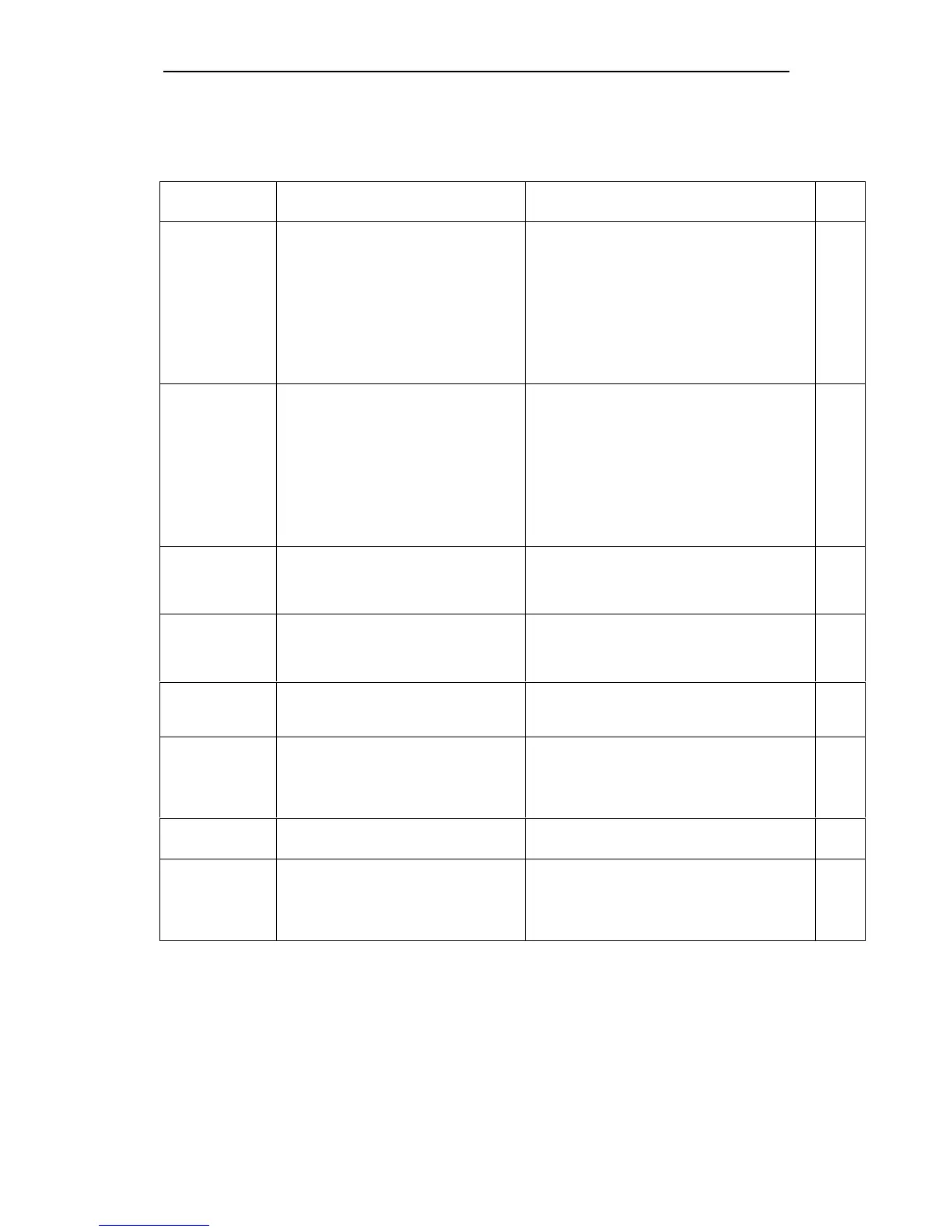

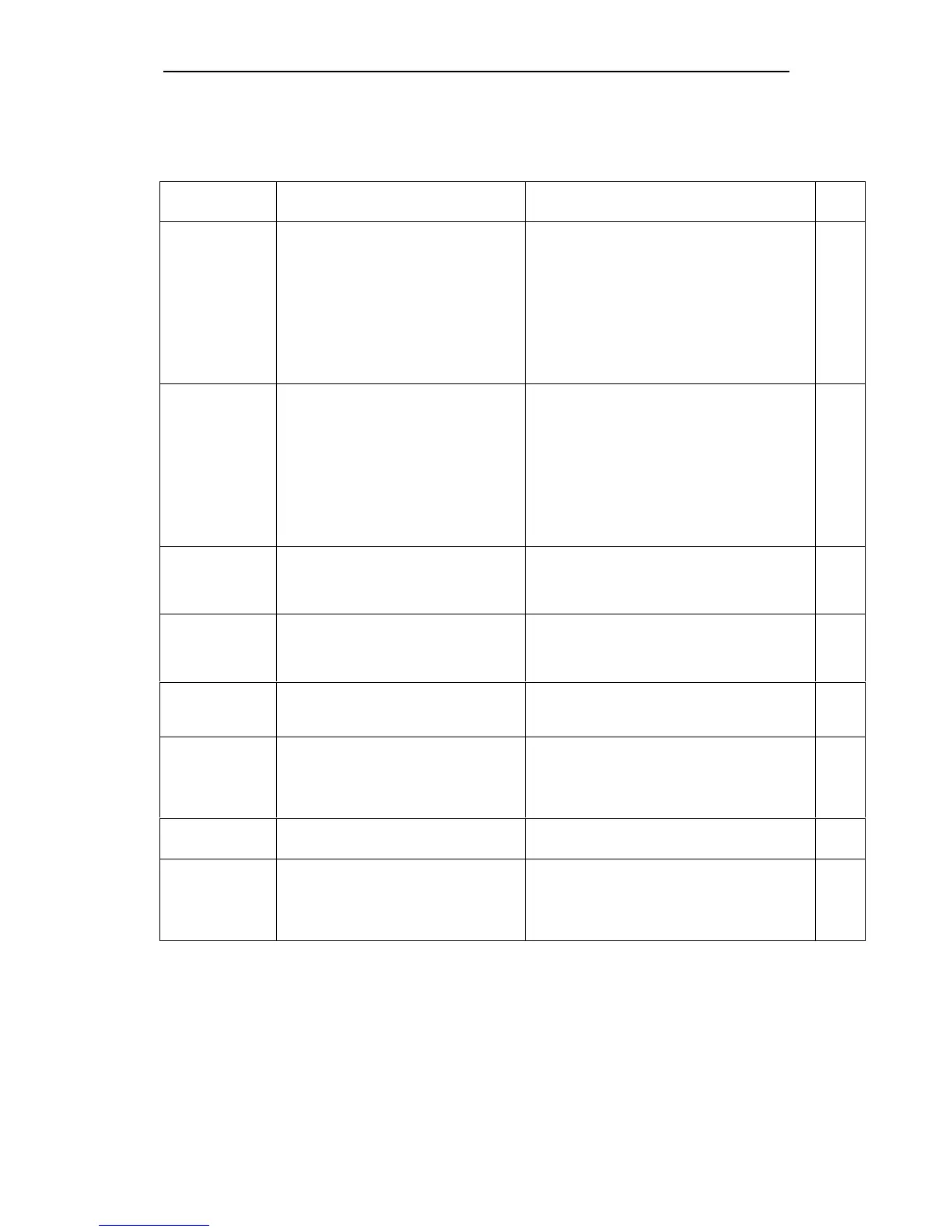

6.3 Fault messages

Fault Possible Causes Diagnose & Remedy Reac-

tion

F0001

OverCurrent

Motor power (P0307) does not

correspond to the inverter power (P0206)

Motor lead short circuit

Earth faults

Check the following:

1. Motor power (P0307) must correspond to inverter

power (P0206).

2. Cable length limits must not be exceeded.

3. Motor cable and motor must have no short-

circuits or earth faults

4. Motor parameters must match the motor in use

5. Value of stator resistance (P0350) must be

correct

6. Motor must not be obstructed or overloaded

Increase the ramp time

Reduce the boost level

Off2

F0002

OverVoltage

DC-link voltage (r0026) exceeds trip level

(P2172)

Overvoltage can be caused either by too

high main supply voltage or if motor is in

regenerative mode.

Regenerative mode can be cause by fast

ramp downs or if the motor is driven from

an active load.

Check the following:

1. Supply voltage (P0210) must lie within limits

indicated on rating plate .

2. DC-link voltage controller must be enabled

(P1240) and parameterized properly.

3. Ramp-down time (P1121) must match inertia of

load.

4. Required braking power must lie within specified

limits.

Note

Higher inertia requires longer ramp times; otherwise,

apply braking resistor.

Off2

F0003

UnderVoltage

Main supply failed.

Shock load outside specified limits.

Check the following:

1. Supply voltage (P0210) must lie within limits

indicated on rating plate.

2. Supply must not be susceptible to temporary

failures or voltage reductions.

Off2

F0004

Inverter Over

Temperature

Ventilation inadequate

Fan inoperative

Ambient temperature is too high.

Check the following:

1. Fan must turn when inverter is running

2. Pulse frequency must be set to default value

Ambient temperature could be higher than specified

for the inverter

Off2

F0005

Inverter I2T

Inverter overloaded.

Duty cycle too demanding.

Motor power (P0307) exceeds inverter

power capability (P0206).

Check the following:

1. Load duty cycle must lie within specified limits.

2. Motor power (P0307) must match inverter power

(P0206)

Off2

F0011

Motor Over

Temperature

Motor overloaded Check the following:

1. Load duty cycle must be correct

2. Motor nominal overtemperatures (P0626-P0628)

must be correct

3. Motor temperature warning level (P0604) must

match

Off1

F0012

Inverter temp.

signal lost

Wire breakage of inverter temperature

(heatsink) sensor

Off2

F0021

Earth fault

Fault occurs if the sum of the phase

currents is higher than

5 % of the nominal inverter current.

Note

This fault only occurs on inverters that have 3

current sensors. Frame sizes D to F

Off2

http://nicontrols.com

Loading...

Loading...