6 Troubleshooting International English

MICROMASTER 440 Operating instructions

72 6SE6400-5CA00-0BP0

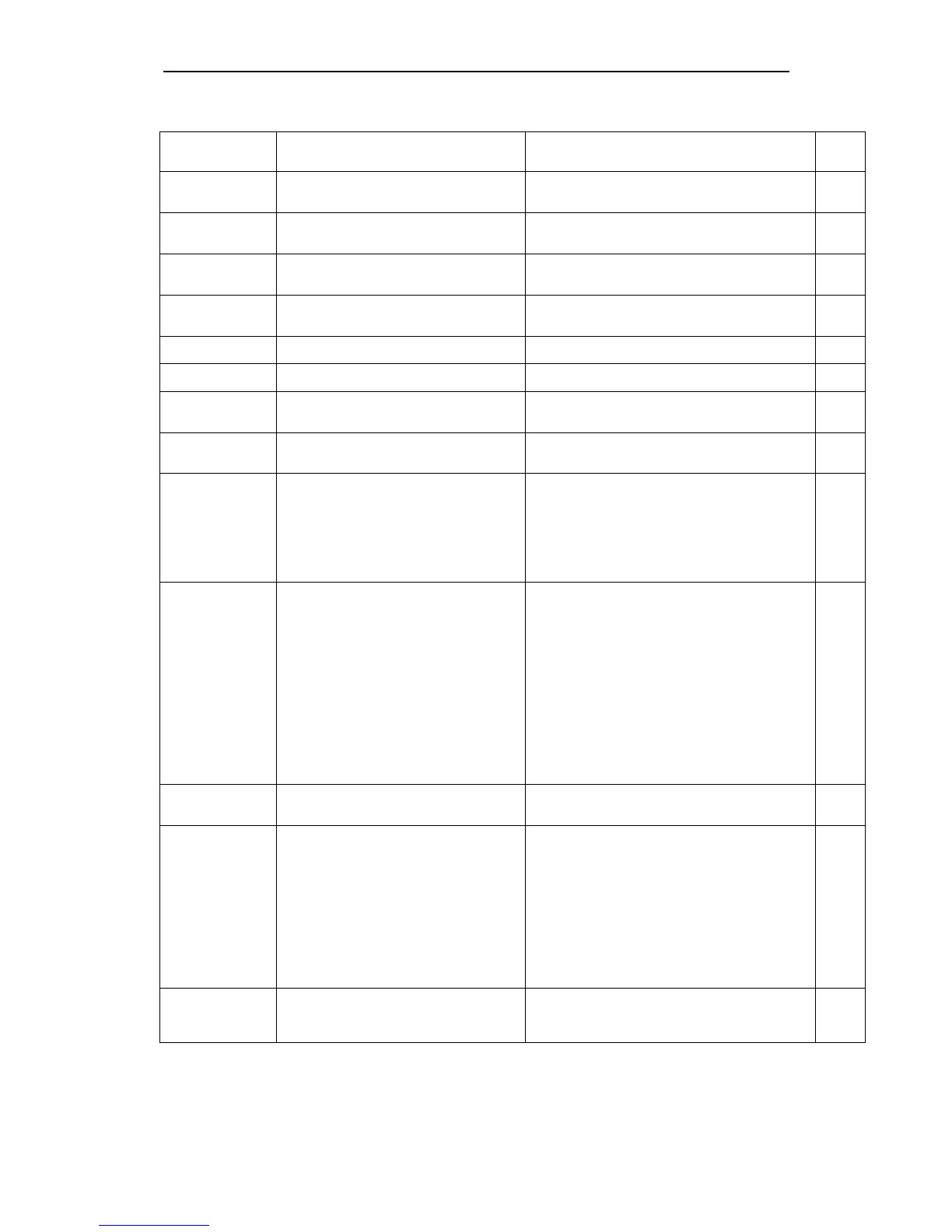

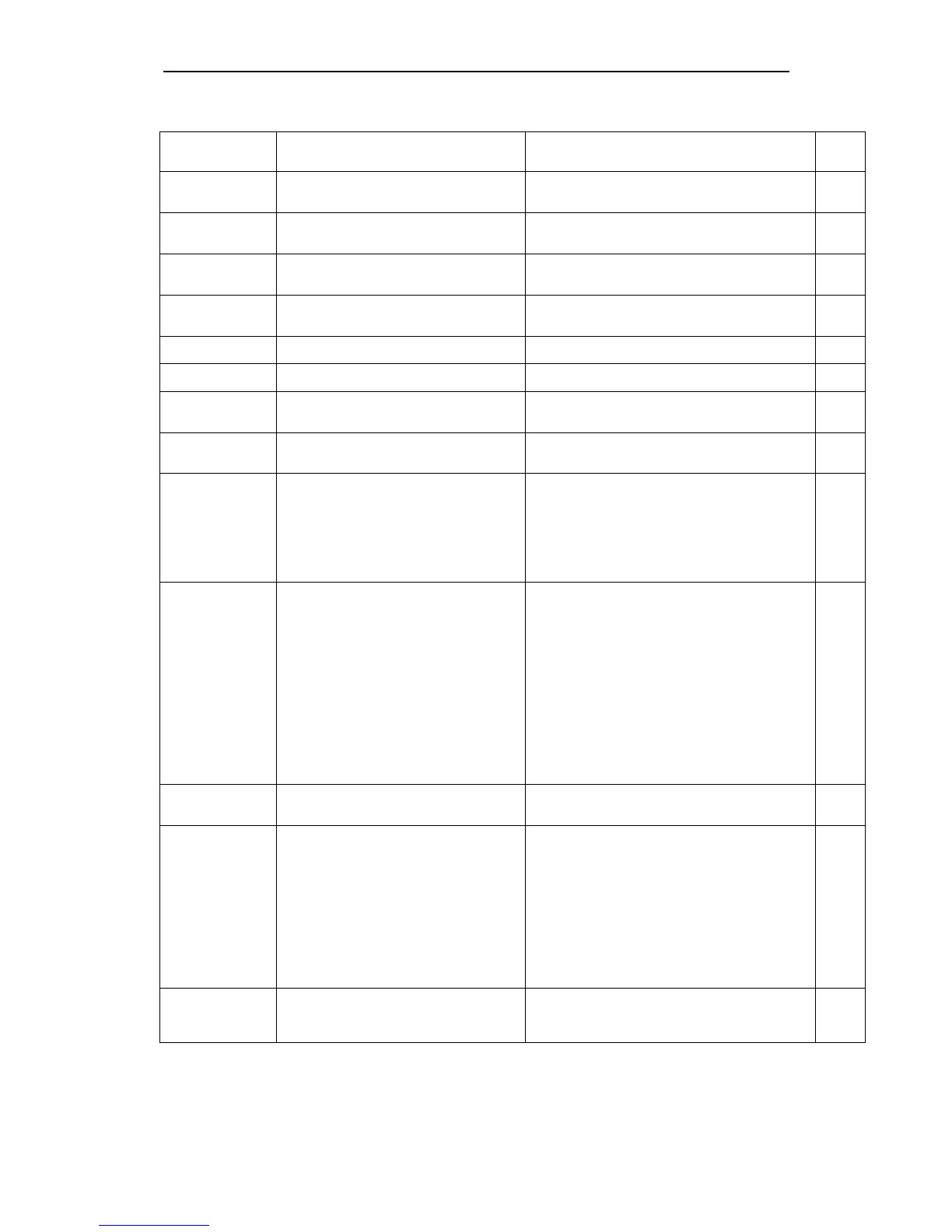

Fault Possible Causes Diagnose & Remedy Reac-

tion

F0070

CB setpoint fault

No setpoint values from CB

(communication board) during telegram

off time

Check CB and communication partner Off2

F0071

USS (BOP-link)

setpoint fault

No setpoint values from USS during

telegram off time

Check USS master Off2

F0072

USS (COMM link)

setpoint fault

No setpoint values from USS during

telegram off time

Check USS master Off2

F0080

ADC lost input

signal

Broken wire

Signal out of limits

Off2

F0085

External Fault

External fault triggered via terminal inputs Disable terminal input for fault trigger. Off2

F0101

Stack Overflow

Software error or processor failure Run self test routines Off2

F0221

PID Feedback

below min. value

PID Feedback below min. value P545. Change value of P545.Adjust feedback gain. Off2

F0222

PID Feedback

above max. value

PID feedback above max. value P544. Change value of P544.Adjust feedback gain. Off2

F0450

BIST Tests Failure

Fault value:

1. Some power section tests have failed

2. Some control board tests have failed

4. Some functional tests have failed

8. Some IO module tests have failed.

(MM 420 only)

16. Internal RAM failed on power-up

check

Drive may run but some features will not work

properly.

Replace drive.

Off2

F0452

Belt Failure

Detected

Load conditions on motor indicate belt

failure or mechanical fault.

Check the following:

1. No breakage, seizure or obstruction of drive train.

2. Proper operation of external speed sensor, if in

use.

3. P0402 (pulse per min at rated speed), P2164

(hysteresis freq. deviation) and P2165 (delay time

for permitted deviation)must have correct values.

4. P2155 (threshold frequency f1), P2157 (threshold

frequency f2)P2159 (threshold frequency

f3)P2174 (upper torque threshold 1)P2175 (lower

torque threshold 1)P2176 (delay T_Torque)P2182

(upper torque threshold 2)P2183 (lower torque

threshold 2)P2184 (upper torque threshold 3) and

P2185 (lower torque threshold 3) must have

correct values.

Off2

F0499

Fault Warning

Separation

Off2

A0501

Current Limit

Motor power does not correspond to the

inverter power

Motor leads are too short

Earth faults

Check the following:

1. Motor power (P0307) must correspond to inverter

power (P0206).

2. Cable length limits must not be exceeded.

3. Motor cable and motor must have no short-

circuits or earth faults

4. Motor parameters must match the motor in use

5. Value of stator resistance (P0350) must be

correct

6. Motor must not be obstructed or overloaded

Increase the ramp-up-time.

Reduce the boost.

--

A0502

Overvoltage limit

Overvoltage limit is reached.

This warning can occur during ramp

down, if the dc-link controller is disabled

(P1240 = 0).

If this warning is displayed permanently, check drive

input voltage .

--

http://nicontrols.com

Loading...

Loading...