08.96 5 PLC Interface

5.3.4 Spindle-specific 611D signals (DB31)

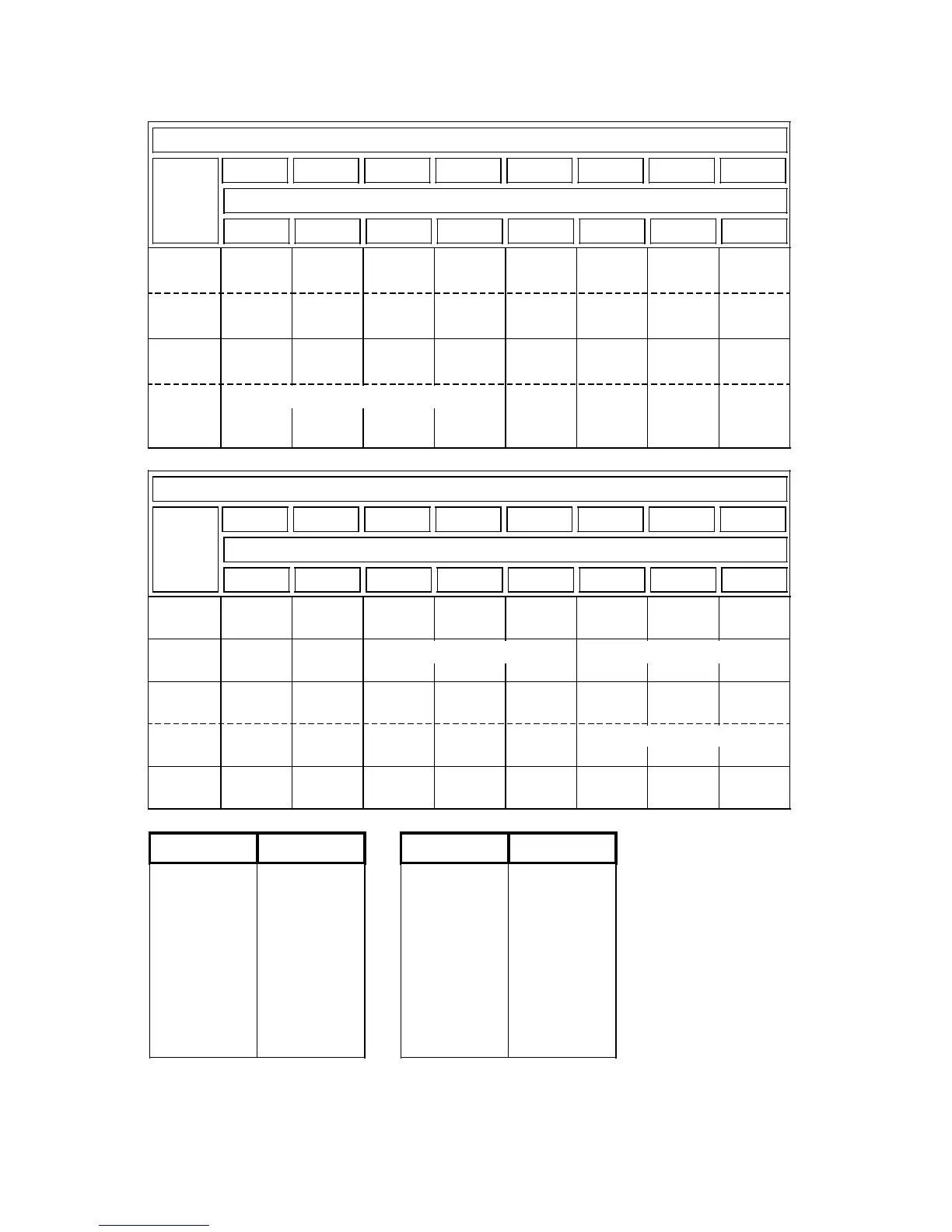

5.3.4.5 Spindle-specific 611D signals

7 6 5 4 3 2 1 0

Bit No.

Byte No.

DL

K+72

Program-

mable

message 6

Program-

mable

message 5

Program-

mable

message 4

Program-

mable

message 3

Program-

mable

message 2

Program-

mable

message 1

Heat sink

temp.

prewarn.

Motor

temp.

prewarn.

DR

K+72

Pulses are

enabled

Drive

connected

Drive

ready

Motor

selection

bit 1

Motor

selection

bit 0

Parameter

set 2

Parameter

set 1

Parameter

set 0

DL

K+73

Traverse

request

drive test

DR

K+73

ZK2 generator

speed <

minimum

speed

generator axis

(MD 1635)

ZK2 emergen-

cy retraction

or DC link gen-

erator active

ZK2 DC link

voltage <

emergency

retraction

threshold

(MD 1634)

ZK2 DC link

voltage <

warning

threshold (MD

1604)

Signals from spindle

15 14 13 12 11 10 9 8

Reserved

7 6 5 4 3 2 1 0

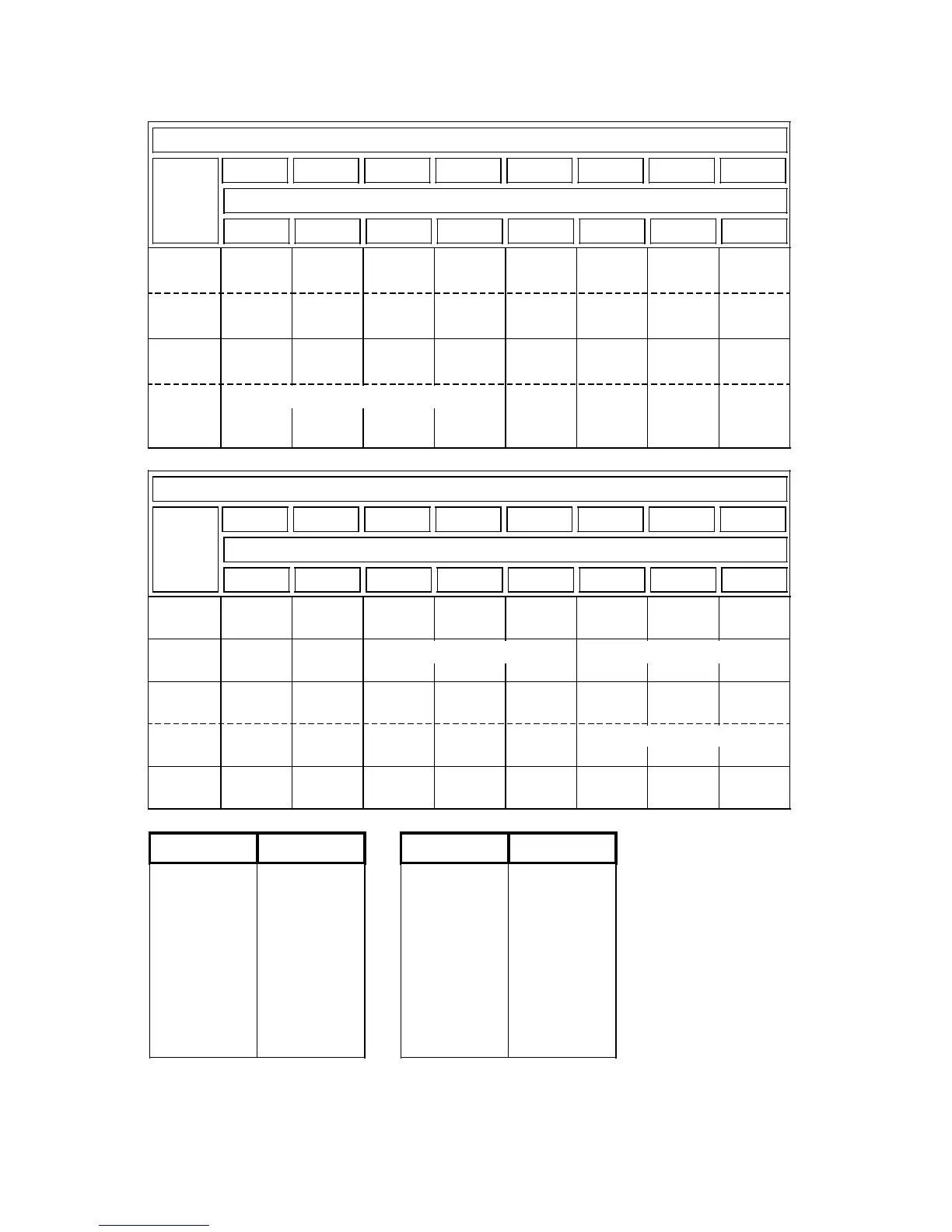

Bit No.

Byte No.

DL

K+50

Parking

spindle

Activate

Slave mode

5)

Gear stage

monitoring

OFF

4)

DR

K+51

DL

K+74

Reserved

611D-AM 1

Reserved

611D-AM 1

Reserved

611D-AM 1

Reserved

611D-AM 1

Speed

setpoint

smooth.

2nd torque

limit.

Ramp-funct.

generator

rapid stop

Second ramp

function gen-

erator V/Hz

6)

DR

K+74

Pulse

enable

Integrator

disable

Motor

selection

transmitted

Motor

selection

bit 1

Motor

selection

bit 0 2 1 0

DL

K+75

Motion

enable drive

test

Signals to spindle

15 14 13 12 11 10 9 8

Position control parameter group *Ratio parameter group *

Drive 611D parameter group

Axis Address K Axis Address K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0

4

8

12

16

20

24

28

32

36

40

44

48

52

56

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

60

64

64

72

76

80

84

88

92

96

100

104

108

112

116

3) Up to SW 2 5) SW 4.4 and higher * SW 4 and higher

4) SW 3 and higher 6) SW 5 and higher

© Siemens AG 1992 All Rights Reserved 6FC5197- AA60 5–39

SINUMERIK 840C (IA)

Loading...

Loading...