Motor components (options)

5.4 Gearbox

1PH7 induction motors (Machine tools)

202 Configuration Manual, (APH7W), 04/2009, 6SN1197-0AD72-0BP0

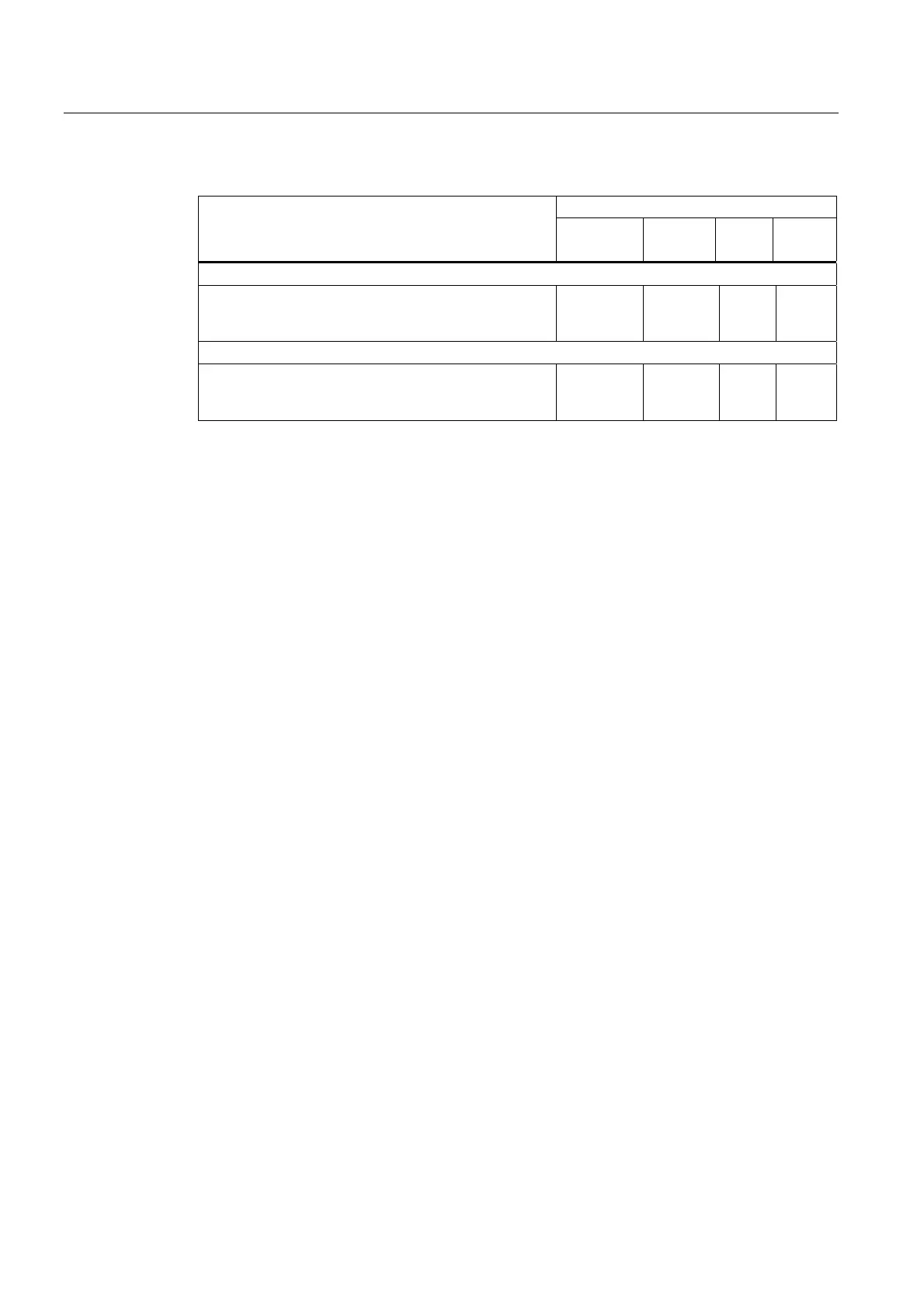

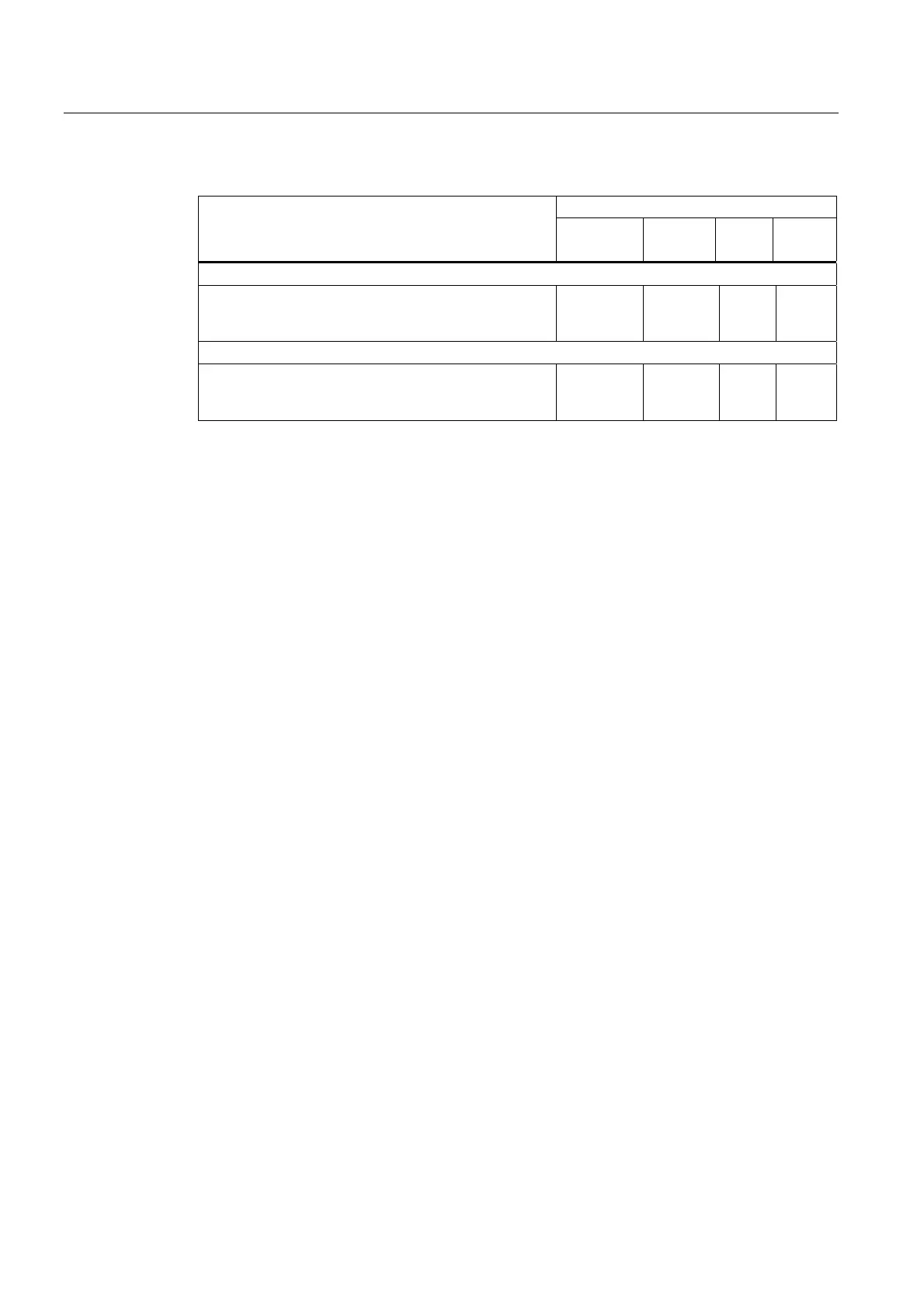

Table 5- 8 Control sequence when selecting the gearbox stage

Connector contact No.

Gearbox stage selection

2 3 4/5

(S1)

5/6

(S2)

When changing the ratio from stage i

2

to i

1

a Initial setting (f)

b Selection sequence

c Mechanical selection carried out up to endstop

1)

+24 V DC 0 V 0

0

L

L

0

0

When changing the ratio from stage i

1

to i

2

d Initial setting (c)

e Selection sequence

f Mechanical selection carried out up to endstop

1)

0 V +24 V DC L

0

0

0

0

L

L Contact closed

0 Contact open

1)

After a gear stage has been selected a limit switch (S1 or S2) sends a signal to the control to

switch off the selector unit.

5.4.7 Lubrication

Splash lubrication

Oil level check: Visually using a sight glass

The oil level depends on the mounting position:

horizontally and vertically: Middle of sight glass

1)

For an inclined mounting

position:

Mark on the angled oil level indicator (mount additionally)

Oils which can be used: HLP 32 acc. to ISO-VG 68

Oil drain bolts: on both sides

1) The oil volume data on the rating plate is only an approximate value

Circulating oil lubrication

Circulating oil lubrication is required for the following applications:

● for continuous operation

● for operation over a longer period of time in one gearbox stage

● for intermittent operation with short no-load intervals

The type of circulating oil lubrication depends on which operating temperature level is

required in use. Several applications require a low operating temperature level.

We recommend, in these cases, circulating oil lubrication.

The oil flow rate is between 1 and 1.5 l/min with an oil pressure of approx. 1.5 bar.

Loading...

Loading...