Feedrate Control and Spindle Motion

7.11 Constant cutting rate (G96/G961/G962, G97/G971/G972, G973, LIMS, SCC[AX])

Fundamentals

306 Programming Manual, 11/2006, 6FC5398-1BP10-2BA0

7.11 Constant cutting rate (G96/G961/G962, G97/G971/G972, G973, LIMS,

SCC[AX])

Function

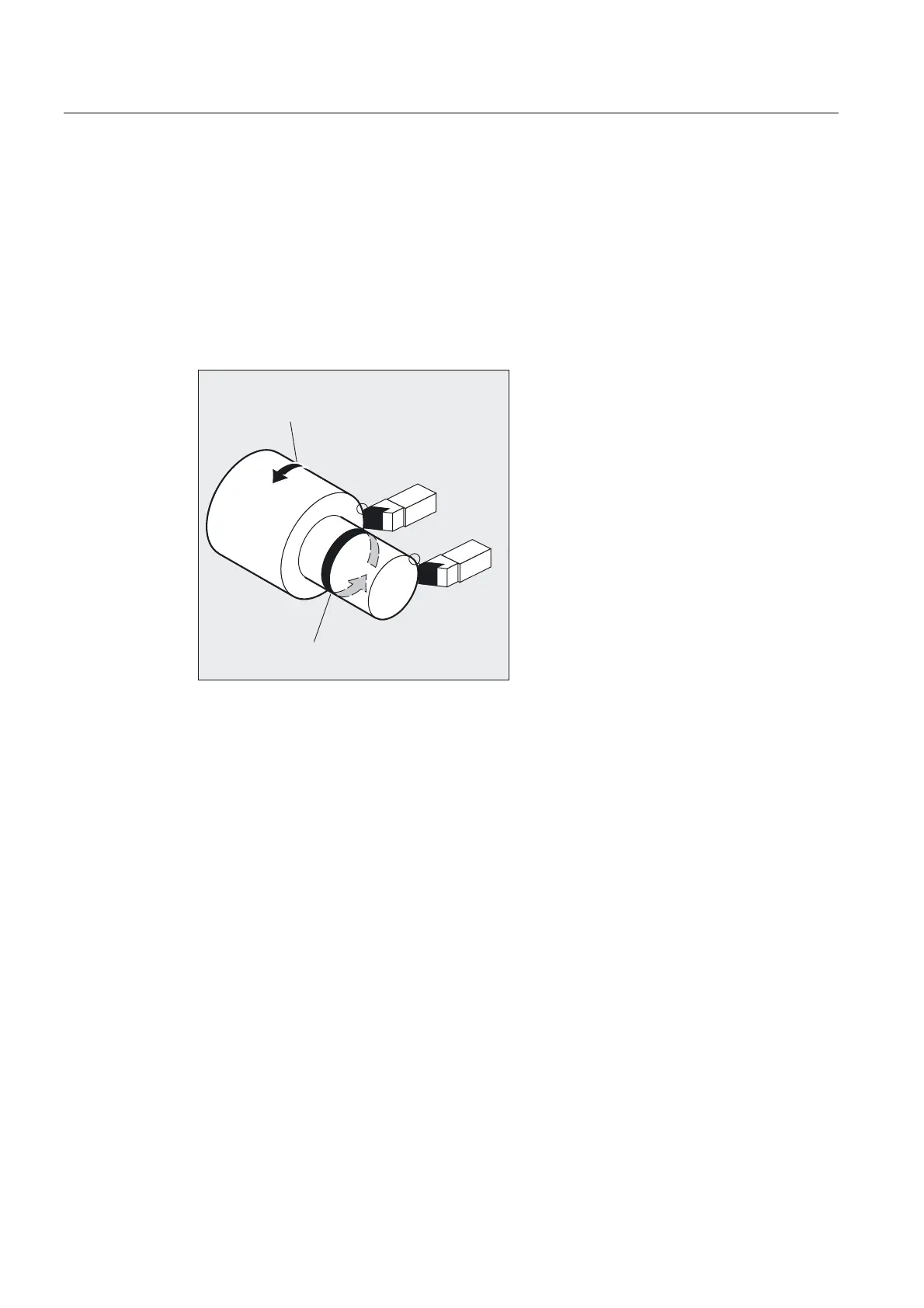

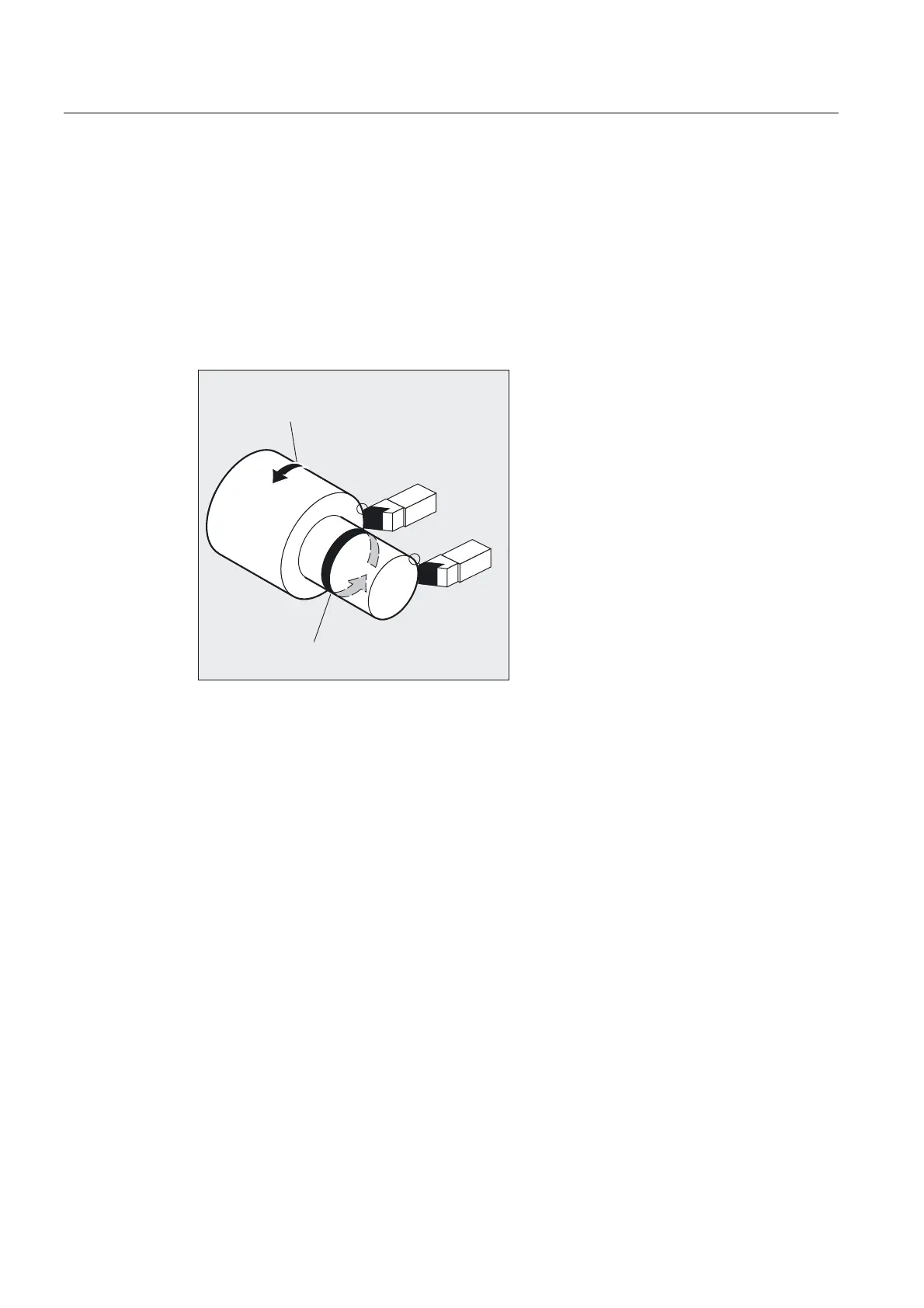

When G96/G961 is active, the spindle speed – depending on the respective workpiece

diameter – is modified in order that the cutting rate S in m/min or ft/min remains constant at

the tool edge.

6SLQGOHVSHHG

5HGXFH

&RQVWDQW

FXWWLQJUDWH

6SLQGOHVSHHG

LQFUHDVHG

This increases the uniformity and thus the surface quality of turned parts, and also protects

the tool.

The constant cutting rate, activated with G96/G961/G962 can be cancelled again with

G97/G971/G972 with the active feed type (G94 linear feed or G95 revolutional feedrate).

Using G973 a constant cutting rate (G96) is de-selected without speed limiting being

activated as is the case for G97.

If any of the G96/G961/G962 functions are active, SCC[axis] can be used to assign any

geometry axis as a reference axis. If the reference axis changes, which will in turn affect the

TCP (tool-center-point) reference position for the constant cutting rate, the resulting spindle

speed will be attained via the set braking or acceleration ramp.

The command LIMS specifies a maximum spindle speed limitation for the master spindle.

Loading...

Loading...