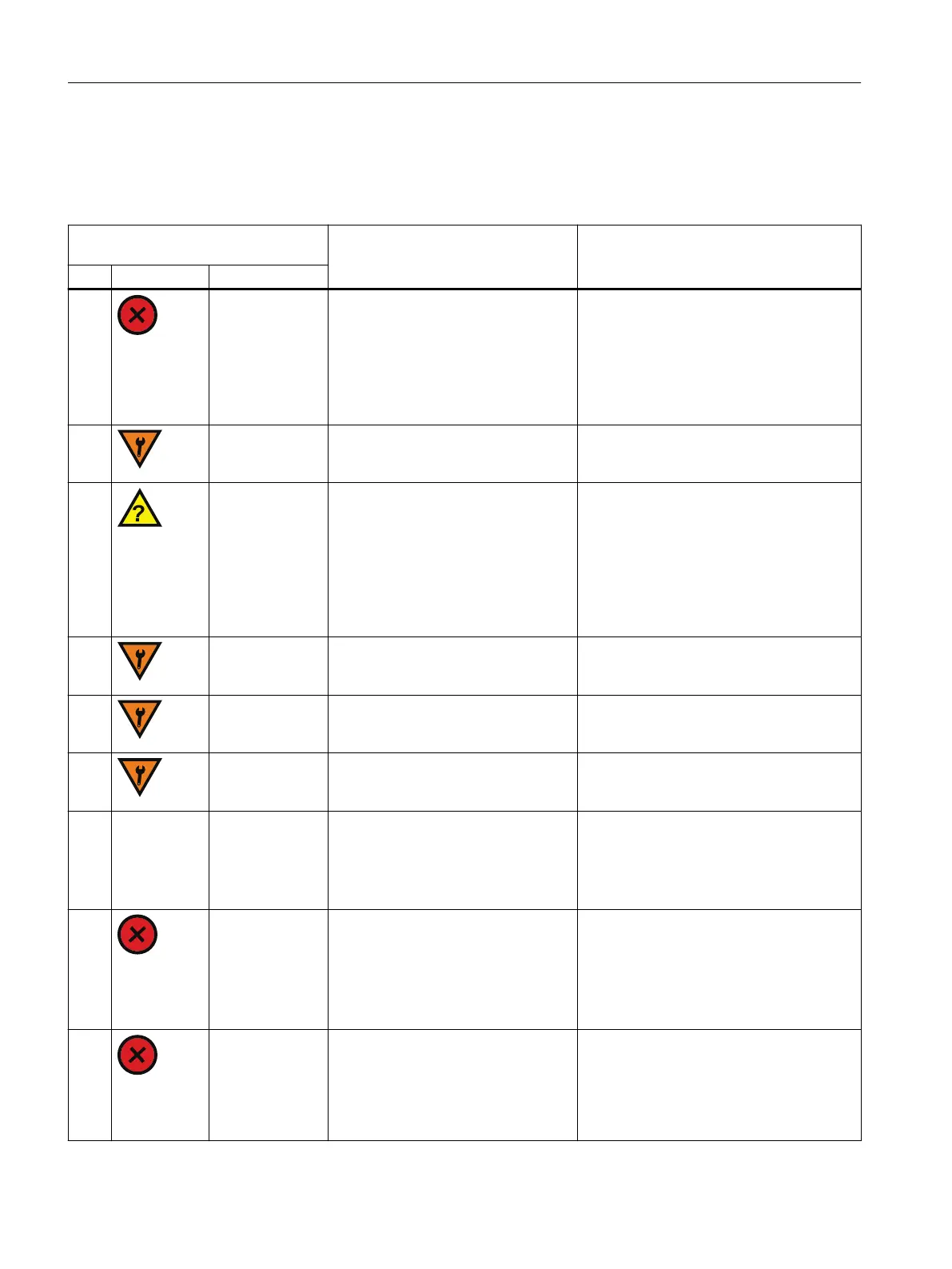

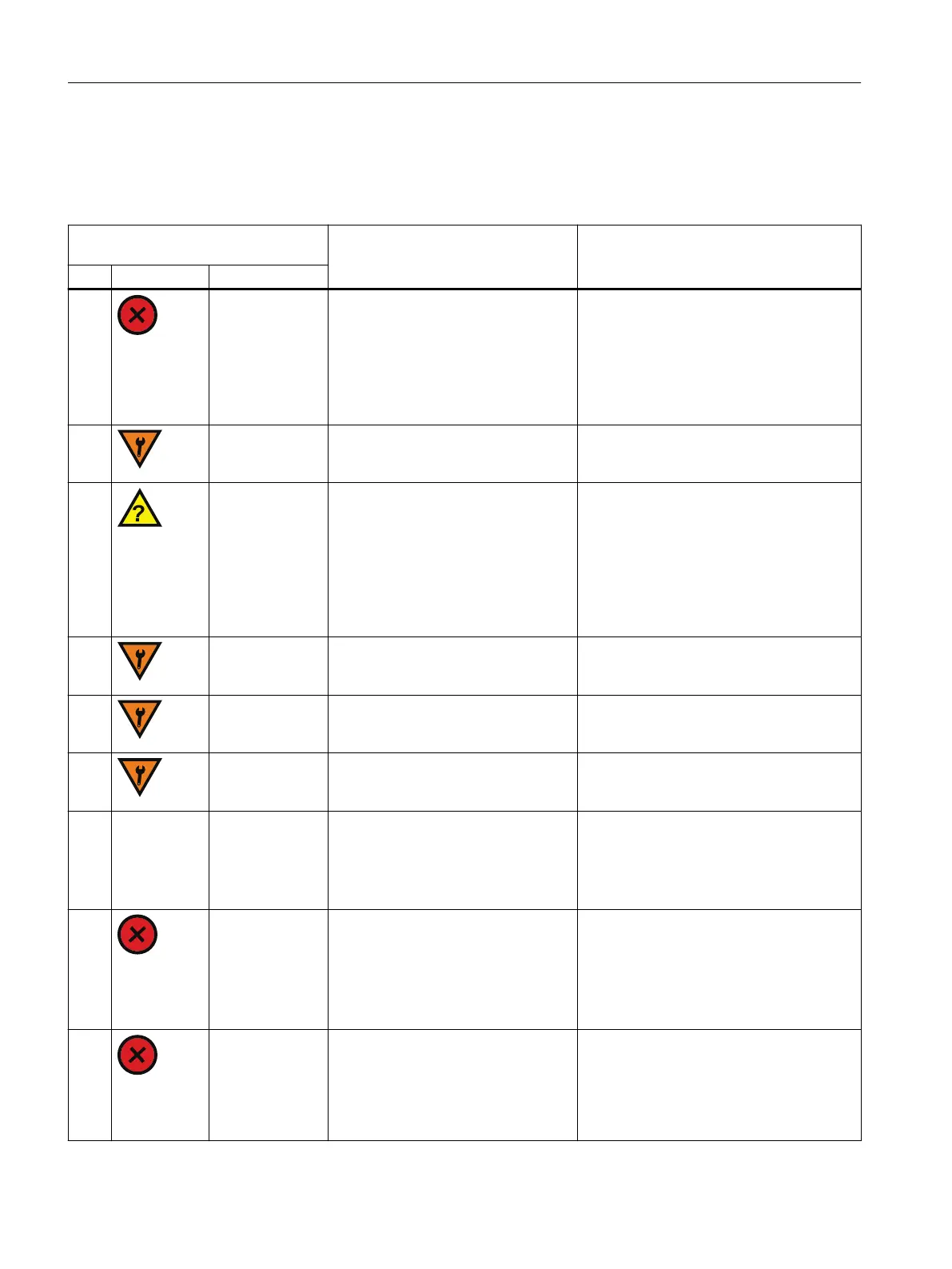

9.2 Info IDs, error messages and corrective measures

The following table shows the IDs of diagnostic messages and possible causes and instructions

for corrective actions.

Messages on the local display

(Page37)

Meaning / cause

Remedy

ID Symbol Status line

6A NO MOVEMENT

• Errors during initialization

• Insucient supply of compressed

air

• Mounting kit not correctly moun‐

ted.

• Valve blocked

Eliminate the cause. Start the initialization

process.

6C NO INIT + set‐

point as percent‐

age

Positioner is not initialized Press left button to start the initialization of

the positioner.

6d -

• Measuring range of position de‐

tection exceeded

• Swivel area of the valve is larger

than 110°.

• Positioner installed on a dierent

actuator without re-initialization.

• End positions of valve are worn.

Check the mounting kit and the wear. Start

the initialization process.

6E DI-HOLD + set‐

point as percent‐

age

Maintain valve position is enabled

through digital input (DI).

Congured response. If required, adjust set‐

ting in parameter "DIGITAL IN" [01].

6F DI-GOCL + set‐

point as percent‐

age

Approach valve position is enabled

through digital input (DI).

Congured response. If required, adjust set‐

ting in parameter "CLOSE LIMIT" [05].

6H DI-GOOL + set‐

point as percent‐

age

Approach valve position is enabled

through digital input (DI).

Congured response. If required, adjust set‐

ting in parameter "OPEN LIMIT" [07].

6L - - Digital input (DI) is enabled. This sta‐

tus is reported via the digital output

(DO).

Setting in parameter "BEHAVIOR DI

[01] > MSG"

Not necessary.

6N SPAN TO HIGH

• Maximum angle span exceeded.

• Eective lever arm is not adjusted

to the actuator travel.

• Mounting kit not correctly moun‐

ted.

Position the carrier pin at a larger stroke val‐

ue.

Check the mounting kit.

Use the electropneumatic positioner SI‐

PART PS2 from Siemens with a swivel area of

185° (special design).

6P SPAN TO LOW

• Minimum angle span underrun.

• Eective lever arm is not adjusted

to the actuator travel.

• Mounting kit not correctly moun‐

ted.

Position the carrier pin at a smaller stroke

value.

Check the mounting kit.

Troubleshooting

9.2Info IDs, error messages and corrective measures

SIPART PS100

50 Operating Instructions, 06/2023, A5E50188938-AF

Loading...

Loading...