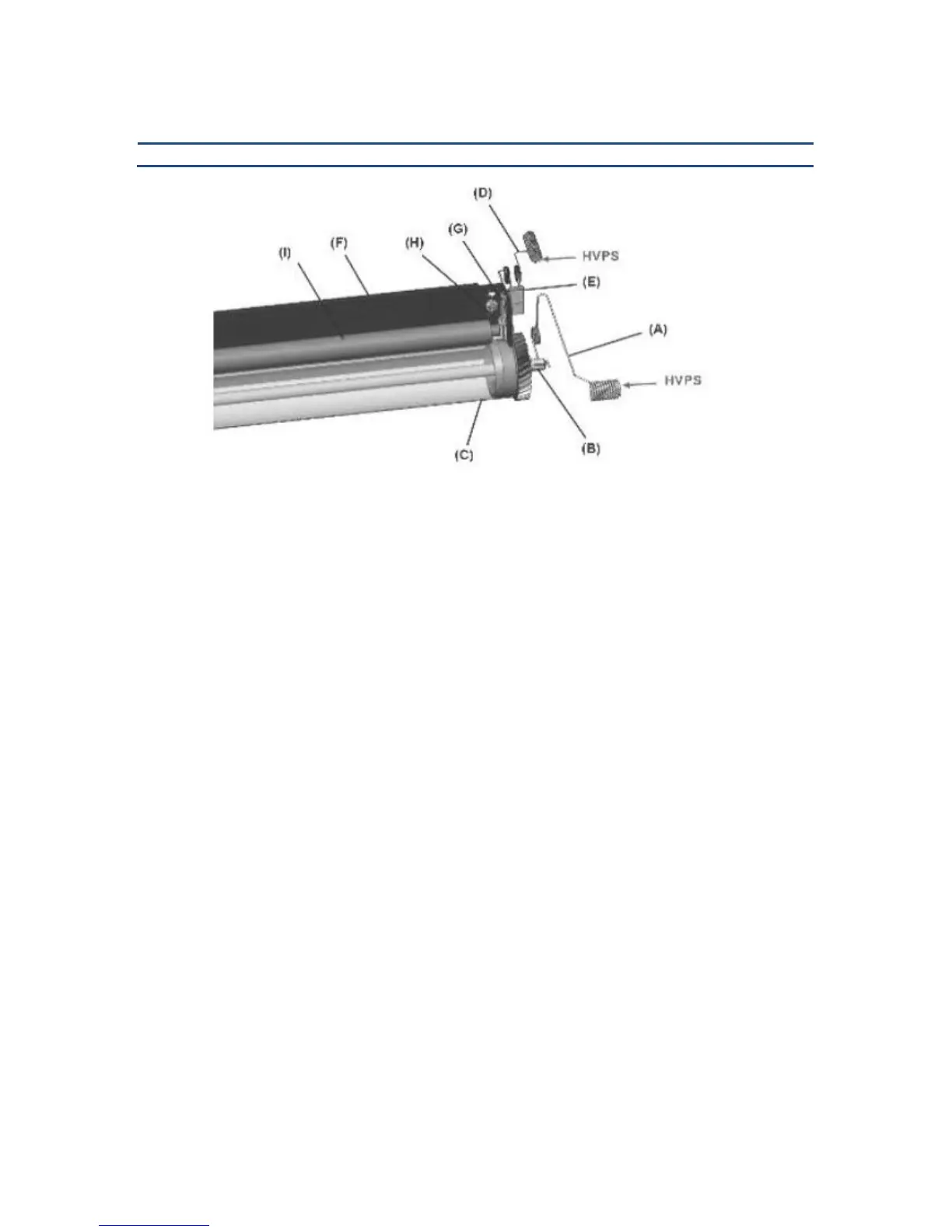

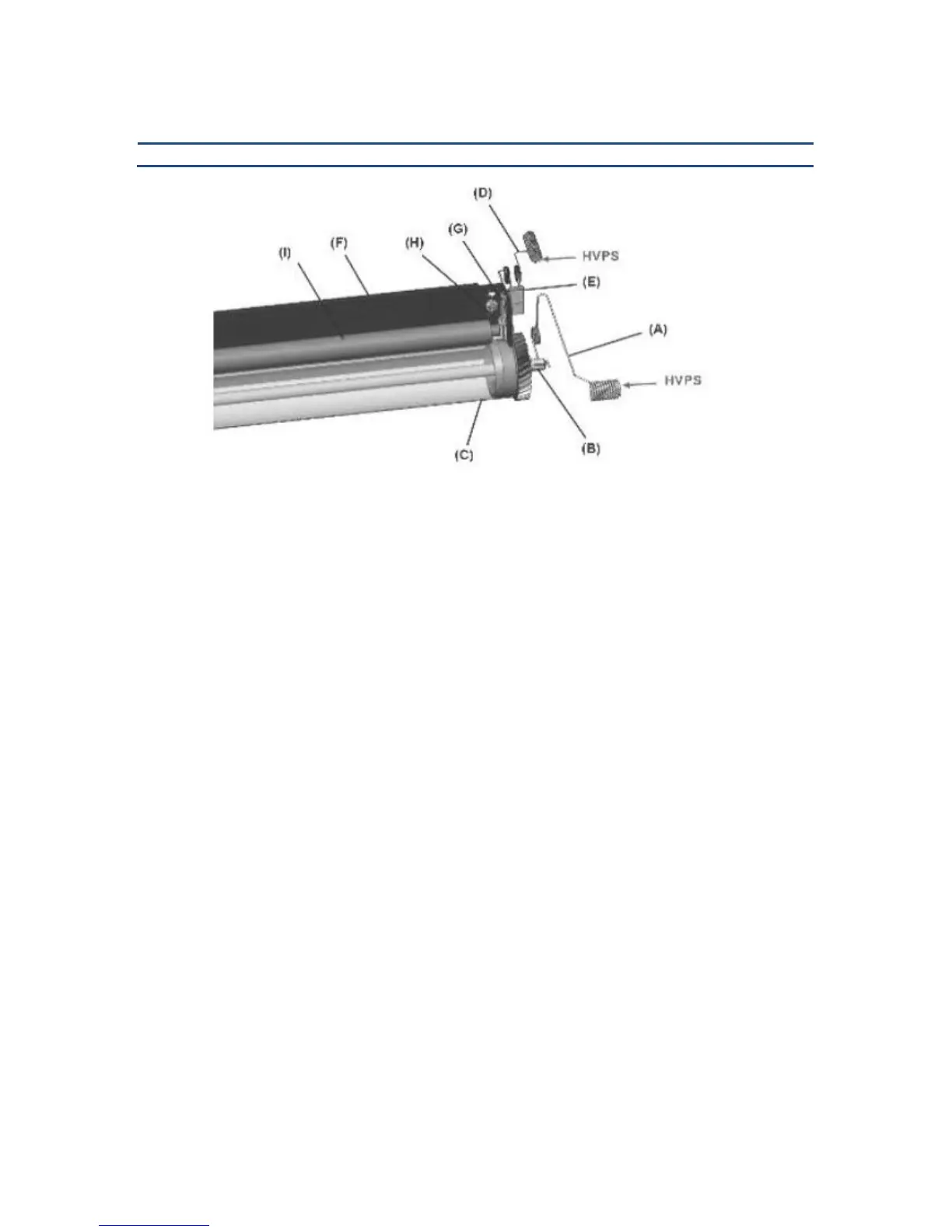

Electrification voltage of -1650V is applied to the electrification roller (I) contacting Drum (C).

The charged voltage is applied to the cleaning blade BKT (F) via electrification voltage applied spring (D)

and electrification voltage applied plate (E), and this applied voltage is delivered to electrification roller

again via electrification roller spring (G) and conductive roller bushing (H). Drum surface gets charged

with about -1100V with this electrification voltage.

Also, -200V of core voltage is applied to drum and this voltage is delivered to drum surface via drum

voltage applied spring (A) and Drum shaft (B) from HVPS. This core voltage is applied to give more

smooth image on half-tone images and somewhat prevents dual image occurrences due to remaining

toner without a separate per-transfer lamp.

Loading...

Loading...