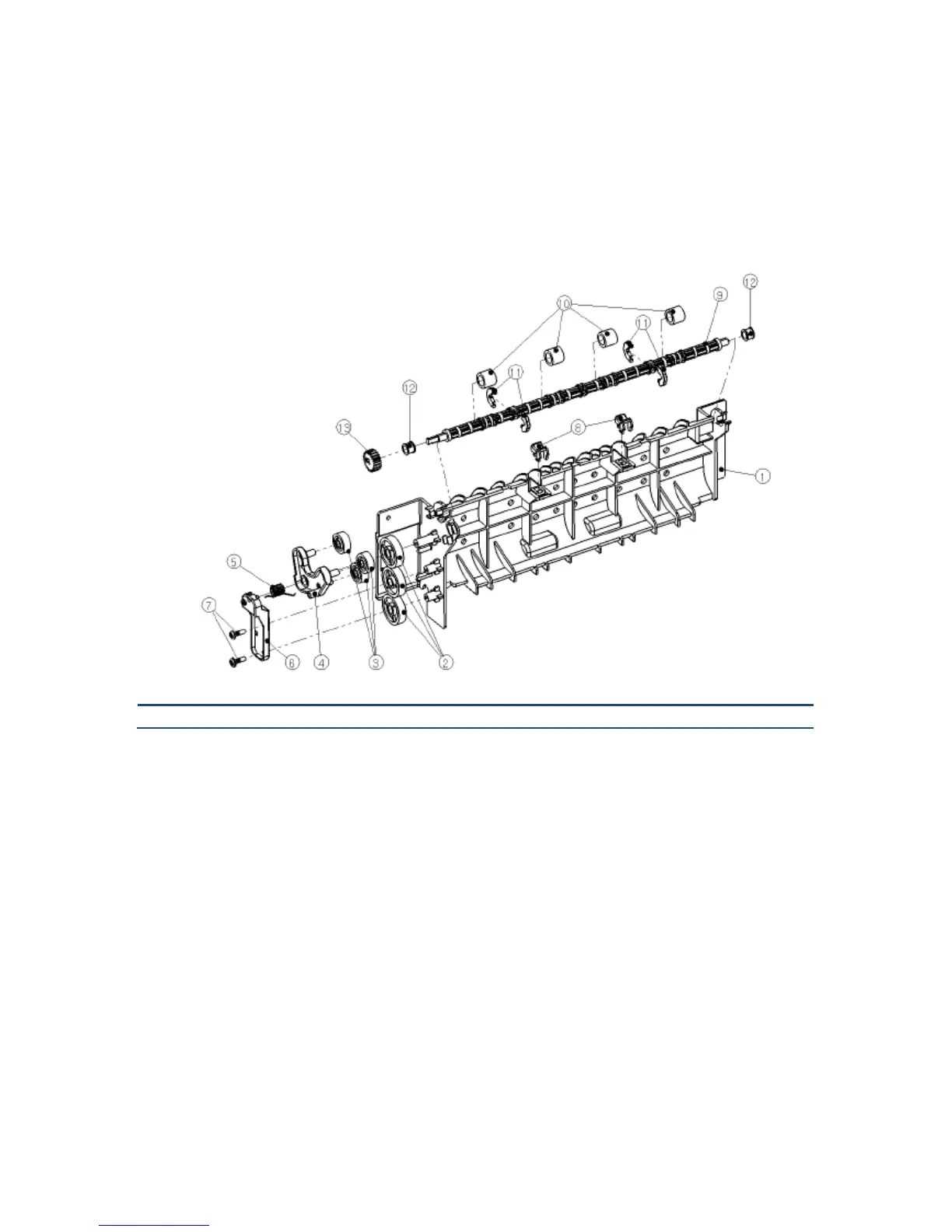

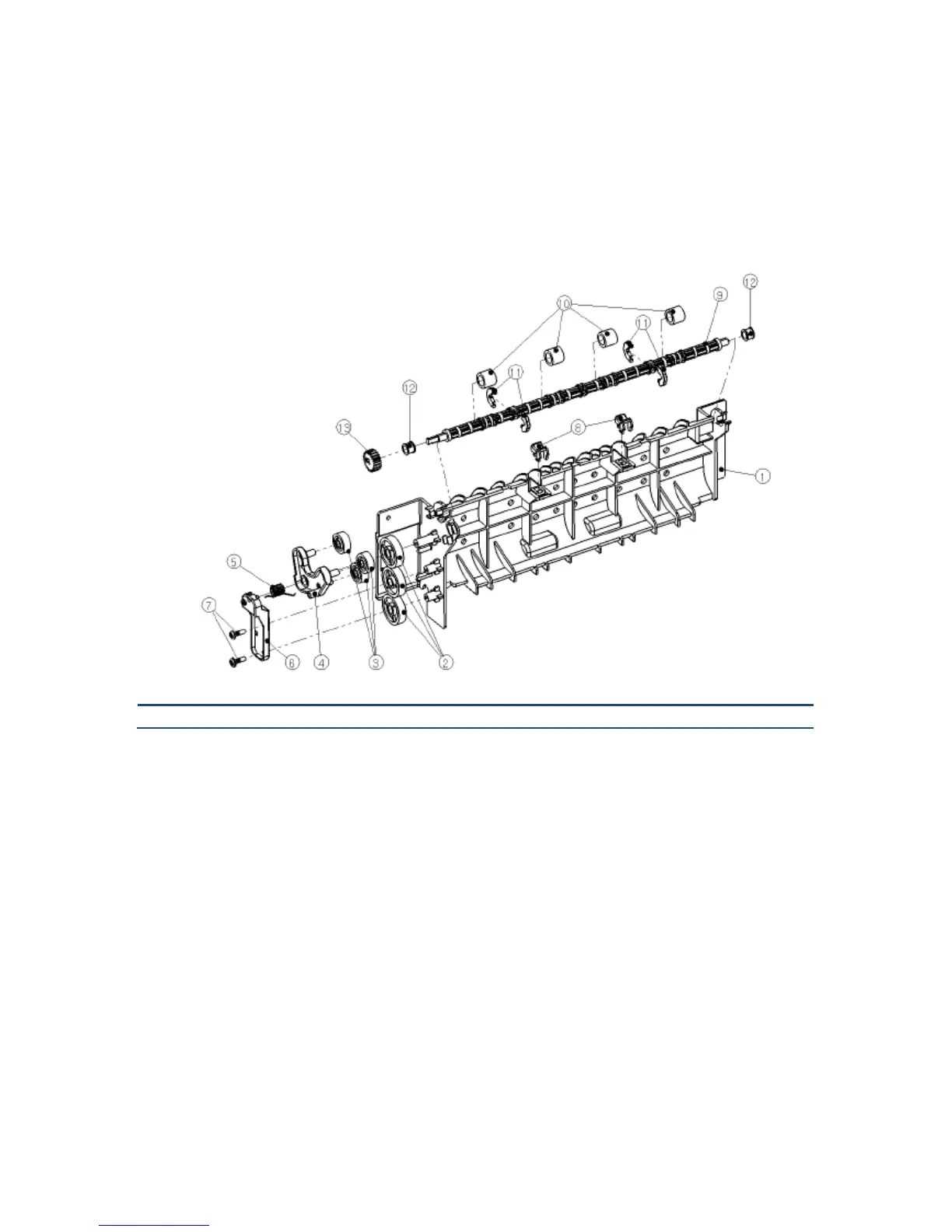

9) Delivery Shaft: Rubber roll and kicker are assembled and connects to rotate

10) Rubber Roller: It’s not delivery shaft built-in, but an assembly type that gives moving force to

papers by working with idle roller assembled to laser cover.

11) Kicker: It performs a function to push backside of paper to get paper discharged completely.

12) Bushing: It reduces friction force of rotation part of delivery shaft

13) Shaft Gear: It delivers rotation force to delivery shaft from small delivery gear.

The papers passed through Fusing unit get transferred to paper proceeding direction by Fusing roller.

The paper fed to Fusing unit first goes through middle delivery shaft and to delivery shaft and the paper

transferred to the shaft and get discharged through Fusing roller and middle shaft that rotates by

delivery shaft. Each shaft always rotates together with main motor operation and allows paper to move.

2 and 4 rubber rollers are assembled on middle delivery shaft and delivery shaft and the rubber rollers

are paired with idle rollers. Each idle roller pressed against rubber rollers by springs to apply friction

force on papers to move.

Loading...

Loading...