When the pickup roller rotates once, the segment gear works with solenoid to isolate power from main

motor and the pickup roller stops its rotation to lower MPT base plate to initial position.

The friction pad isolation method is used for paper isolation method and papers get isolated one by one

with friction pad’s resistance force and friction pad spring’s pressure.

Paper presence detect sensor is installed, so, when all papers in the tray is used, MPT detects it and

stops feeding operation.

As there is no paper size detect sensor, the user must assign the paper size from printer driver and if the

paper size assigned from driver does not match with paper loaded in the tray, a paper jam will occur.

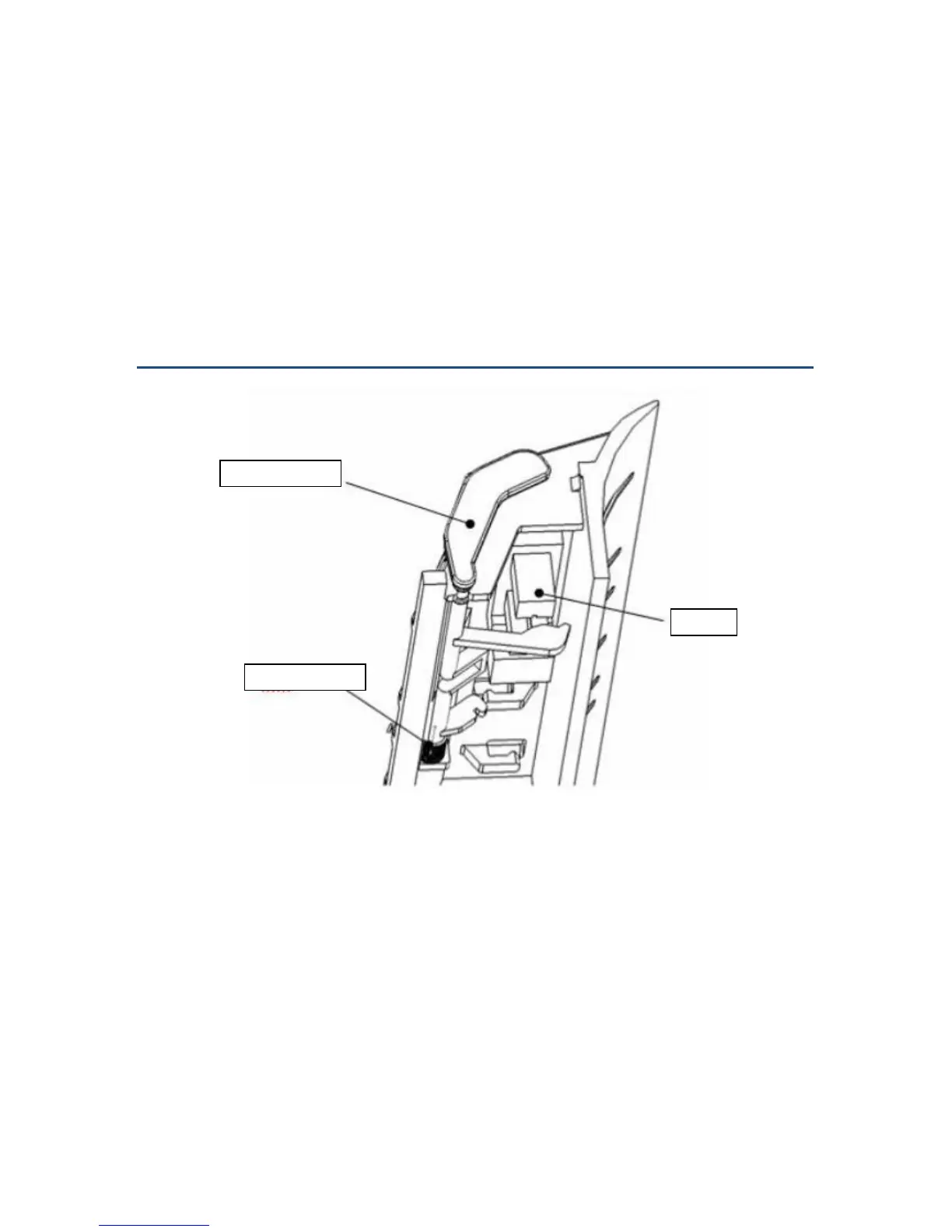

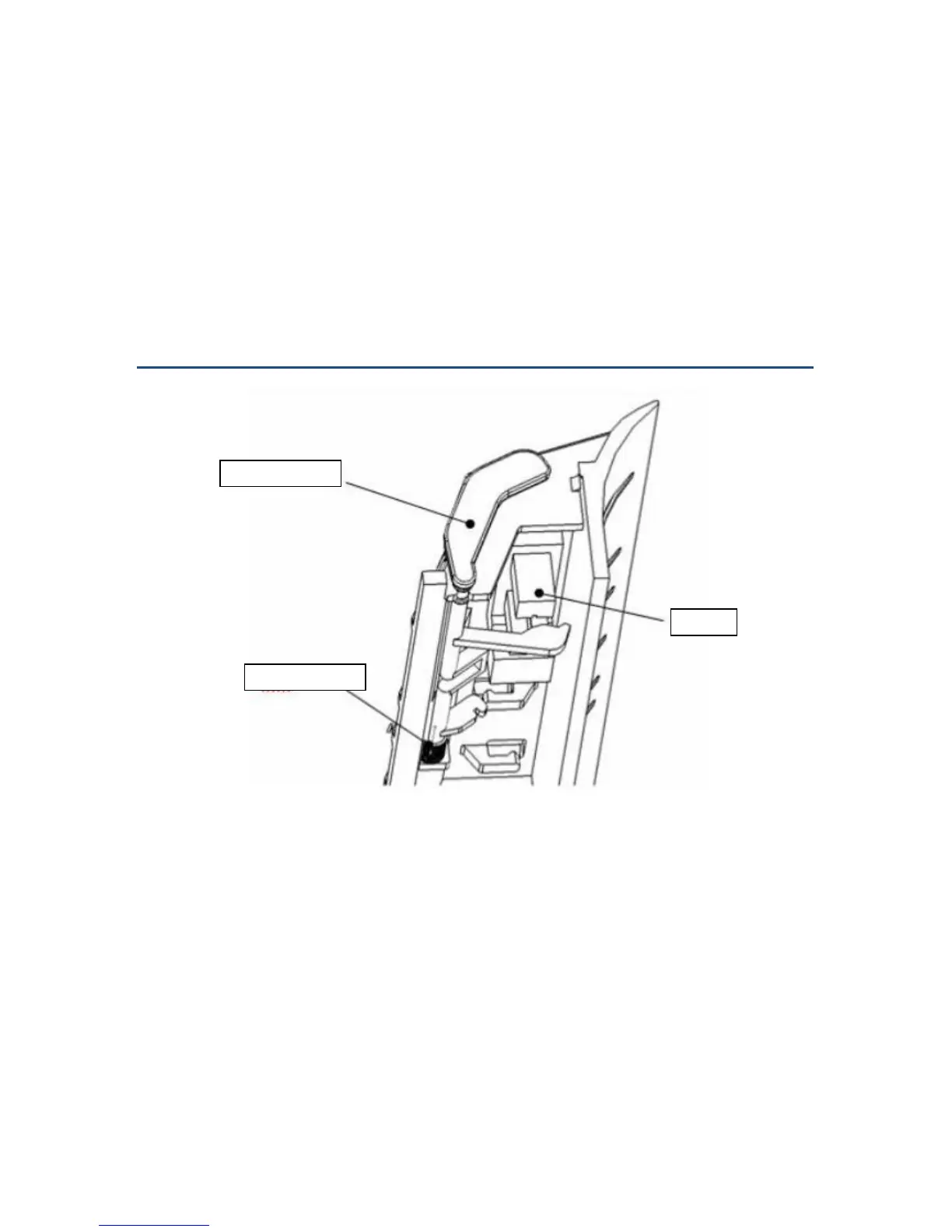

When papers are loaded on MPT, the sensor flag gets pressed and acknowledges paper presence and

when all loaded papers are used, the paper presence detect sensor at the bottom body ASSY returns to

initial position by torsion sprint for sensor flag to isolate the light and causing the sensor’s output value

to change. The printer detects paper presence with this sensor’s output value.

Loading...

Loading...