POWER SYSTEM

TB20J Plus Maintenance Manual 61

© Feb. 2023

Replace and Drain the Fuel Pre-filter

It is recommended to drain the fuel pre-filter daily and

replace the fuel pre-filter element every 6 months or

after 500 hours of operation.

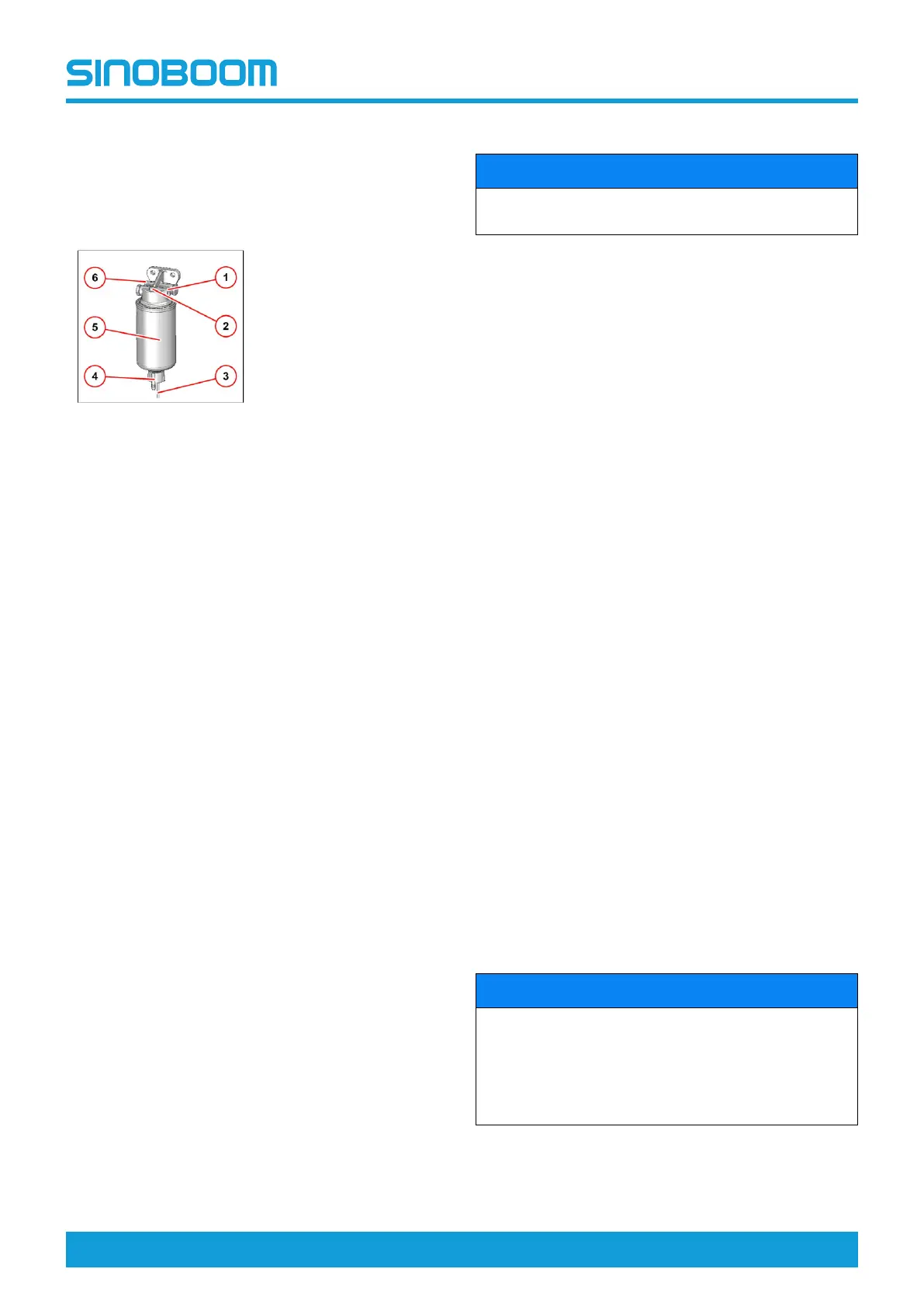

Fig 4 Fuel pre-filter

1. Fuel transfer pump

2. Venting bolt

3. Electrical connection

for level sensor

4. Drain valve

5. Filter element

6. Fuel supply from fuel

tank

Empty water tank:

1. Turn off the engine.

2. Place an appropriate oil-collecting vessel under the

drain valve.

3. Disconnect the cable harness.

4. Open the drain valve to allow the liquid to flow out

completely.

5. Mount the drain valve.

6. Connect the cable connectors.

Replace the fuel pre-filter:

1. Turn off the engine.

2. Close the fuel shut-off valve to disconnect the fuel

supply to the engine (with high-lying tank).

3. Place an appropriate oil-collecting vessel under the

drain valve.

4. Disconnect the cable harness.

5. Open the drain valve to allow all liquid to flow out.

6. Remove the filter element.

7. Clean any dirt off the sealing surface of the new filter

element and opposite side of the filter head with

clean, non-fiber cloths.

8. Apply a thin layer of oil to the sealing surface of the

new filter element.

9. Screw on the new filter by hand until the gasket is

touching, then tighten it with the torque of 17-18Nm

(12.5-13.3ft-lb).

10. Mount the drain valve.

11. Open the fuel shut-off valve to vent the fuel lines.

Vent the Fuel Lines

NOTICE

Failure to vent the fuel lines may bring damage to the

high-pressure pump of the injection system.

The fuel lines is vented through the electric fuel supply

pump.

Note: To avoid false fault messages, do not attempt to

start the fuel system while venting.

1. Ignition: Turn on the electronic fuel supply pump for

20 seconds to vent the fuel lines and build up the re-

quired fuel pressure.

2. Wait until the fuel supply pump is disconnected from

the control unit.

3. Turn off the ignition.

4. Repeat the above steps at least 4 times until the fuel

lines are fully vented.

Lubrication System

Check the Engine Oil Level

1. Turn off the engine.

2. Make sure that the machine and engine are

horizontal.

3. Remove the oil dipstick from the engine and wipe

the dipstick with non-fiber cleaning cloths.

4. Put the clean dipstick back to its original position.

5. Remove the dipstick again and check the oil level,

which should be between the FULL (HOT) mark and

LOW (COLD) mark on the dipstick.

6. If necessary, fill with correct engine oil to the FULL

(HOT) mark on the dipstick according to the Oil Re-

quirements , and do not overfill the tank.

Change the Engine Oil

It is recommended to change the engine oil every 6

months or after 500 hours of operation.

NOTICE

• Every time the engine oil is changed, the engine

oil filter must also be replaced.

• Changing the oil with the engine warmed up can

make the engine oil flow smoother and remove

more impurities.

1. Before changing the oil, warm up the engine so that

the engine oil reaches approximately 80°C (176°F),

and then turn off the engine.

Loading...

Loading...