© Feb. 2023

86 TB20J Plus Maintenance Manual

POWER SYSTEM

It is recommended to replace the fuel filter element

every 6 months or after 500 hours of operation.

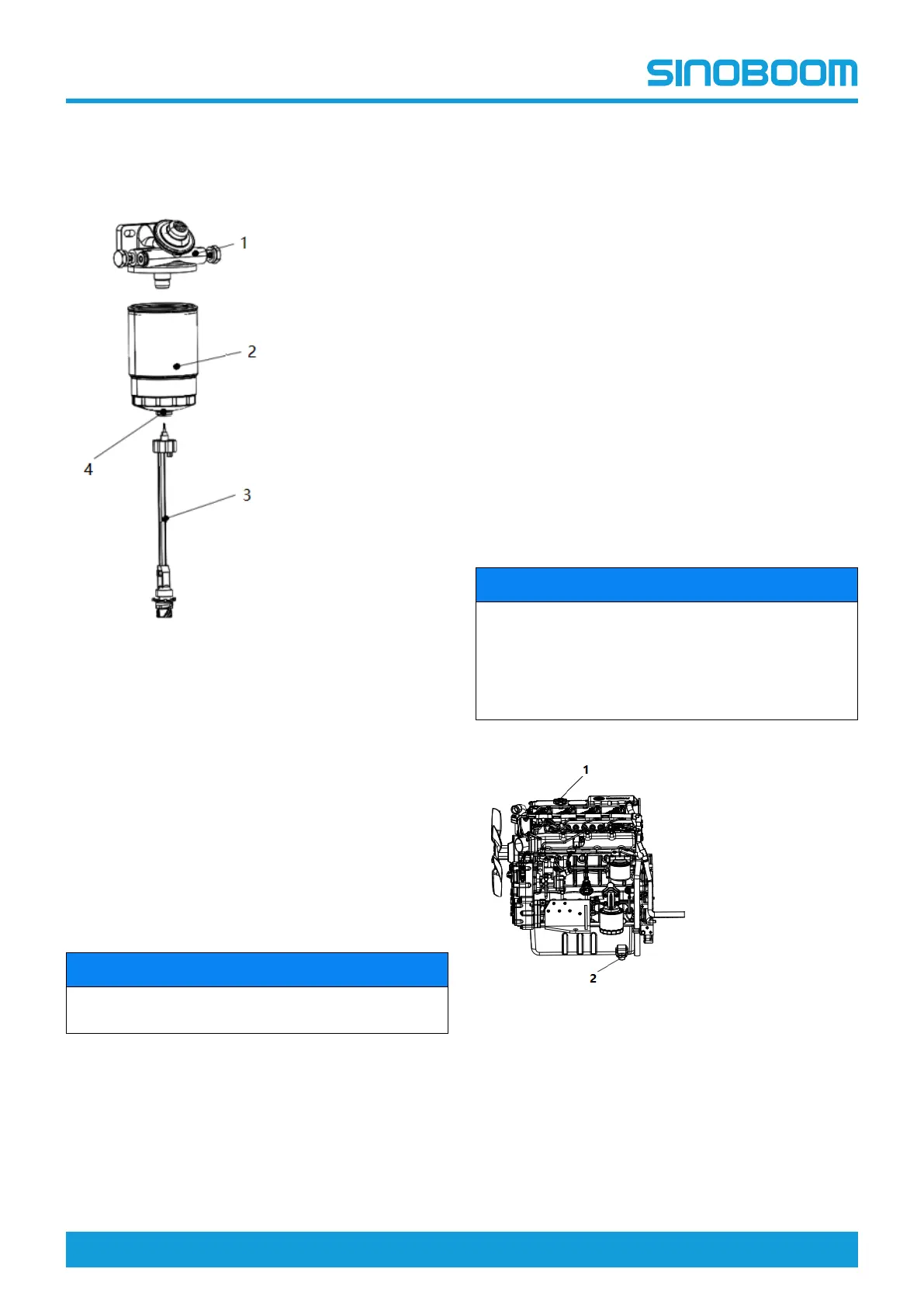

Fig 45 Fuel filter

1. Fuel filter bracket

2. Primary filter

element

3. Water level sensor

4. Waterproof port

1. Turn off the engine.

2. Remove the old fuel filter element and remove the

water collector on the primary filter if it is still usable.

3. Lubricate the seal.

4. Screw on the filter by hand until the seal is con-

nected to the connector.

5. Continue tightening the filter by hand until the filter

is securely seated (approximately 3/4 turn).

6. Perform leakage test.

Vent the Fuel Lines

NOTICE

Failure to vent the fuel lines may bring damage to the

high-pressure pump of the injection system.

To avoid false fault messages, do not attempt to start

the fuel system while venting.

1. Open the fuel tank valve and loosen the venting

screw on the fuel pre-filter.

2. Press the hand pump on the fuel pre-filter to vent

the fuel system.

3. Tighten the venting screw.

Lubrication System

Check the Engine Oil Level

1. Turn off the engine.

2. Make sure that the machine and engine are

horizontal.

3. Remove the oil dipstick from the engine and wipe

the dipstick with non-fiber cleaning cloths.

4. Put the clean dipstick back to its original position.

5. Remove the dipstick again and check the oil level,

which should be between the FULL (HOT) mark and

LOW (COLD) mark on the dipstick.

6. If necessary, fill with correct engine oil to the FULL

(HOT) mark on the dipstick according to the Oil Re-

quirements , and do not overfill the tank.

Change the Engine Oil

It is recommended to change the engine oil every 6

months or after 500 hours of operation.

NOTICE

• Every time the engine oil is changed, the engine

oil filter must also be replaced.

• Changing the oil with the engine warmed up can

make the engine oil flow smoother and remove

more impurities.

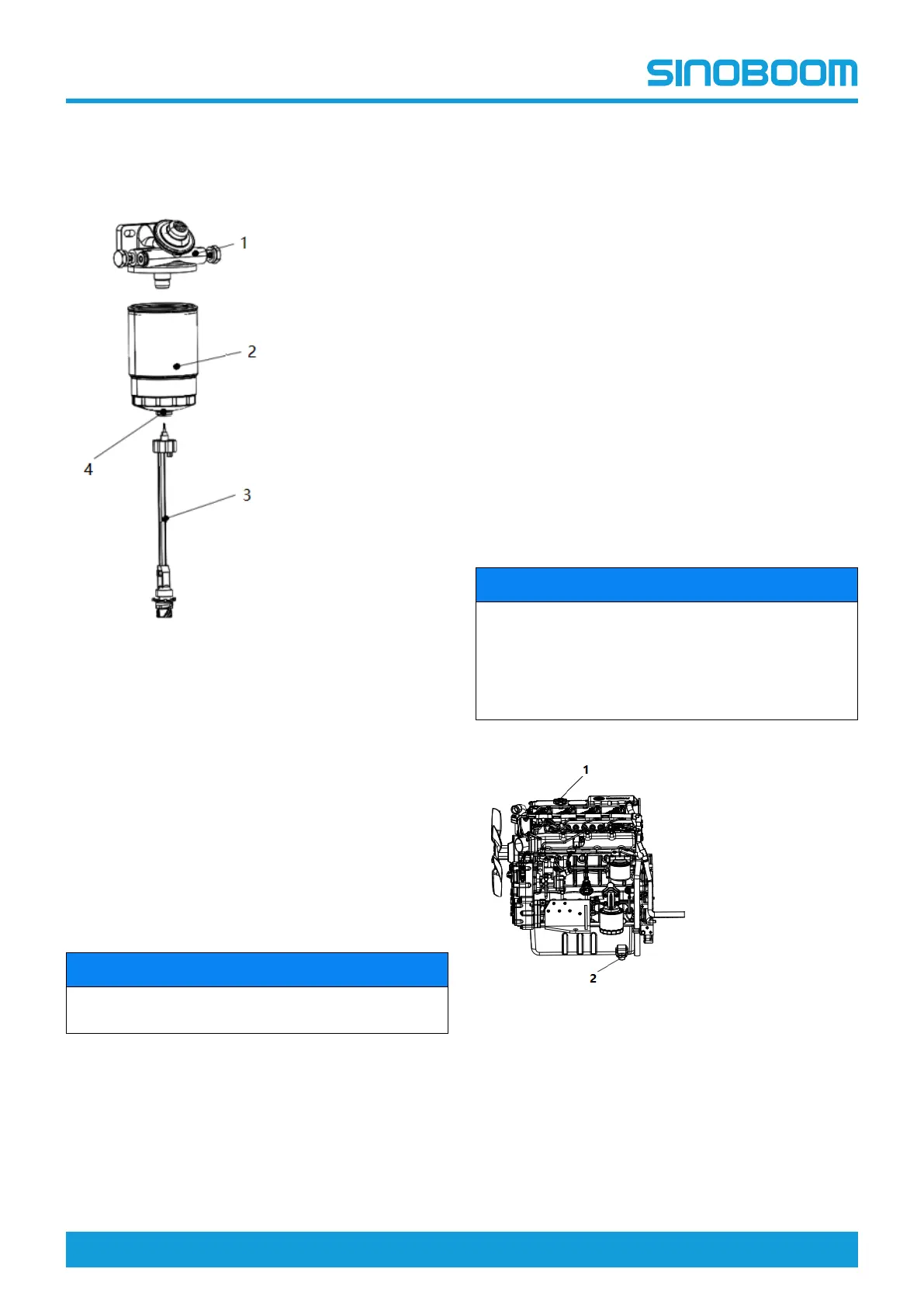

Fig 46

1. Filler cap

2. Drain plug

1. Before changing the oil, warm up the engine so that

the engine oil reaches approximately 80°C (176°F),

and then turn off the engine.

2. Make sure that the machine and engine are

horizontal.

3. Place an appropriate oil-collecting vessel under the

engine oil drain valve.

Loading...

Loading...