Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

5.7 24V auxiliary and I/O power

The family of servo-drives/inverters can be equipped with one or more connectors for connecting 24V

auxiliary power (where required) and I/Os. The following paragraphs describe the pin configuration of the

connectors.

All servo-drive versions feature removable spring-loaded connectors; the acceptable cross-sections of the

cables to be used for wiring are as follows:

Minimum cross-section of solid conductor * ** 0.20 mm

2

Maximum cross-section of solid conductor * ** 1.5 mm

2

Minimum cross-section of flexible conductor * ** 0.20 mm

2

Maximum cross-section of flexible conductor * ** 1.5 mm

2

Minimum cross-section of flexible conductor with terminal * ** 0.25 mm

2

Maximum cross-section of flexible conductor with terminal * ** 0.75 mm

2

*= Use 60/75 °C wires only (UL)

**= Use Copper Conductors only (UL)

Use a flat-head screwdriver to wire the connector; insert the edge of the head into the orange cavity and

press to open the contact. At the same time, insert the cable. It is recommended to use a screwdriver with a

2.5 mm flat head.

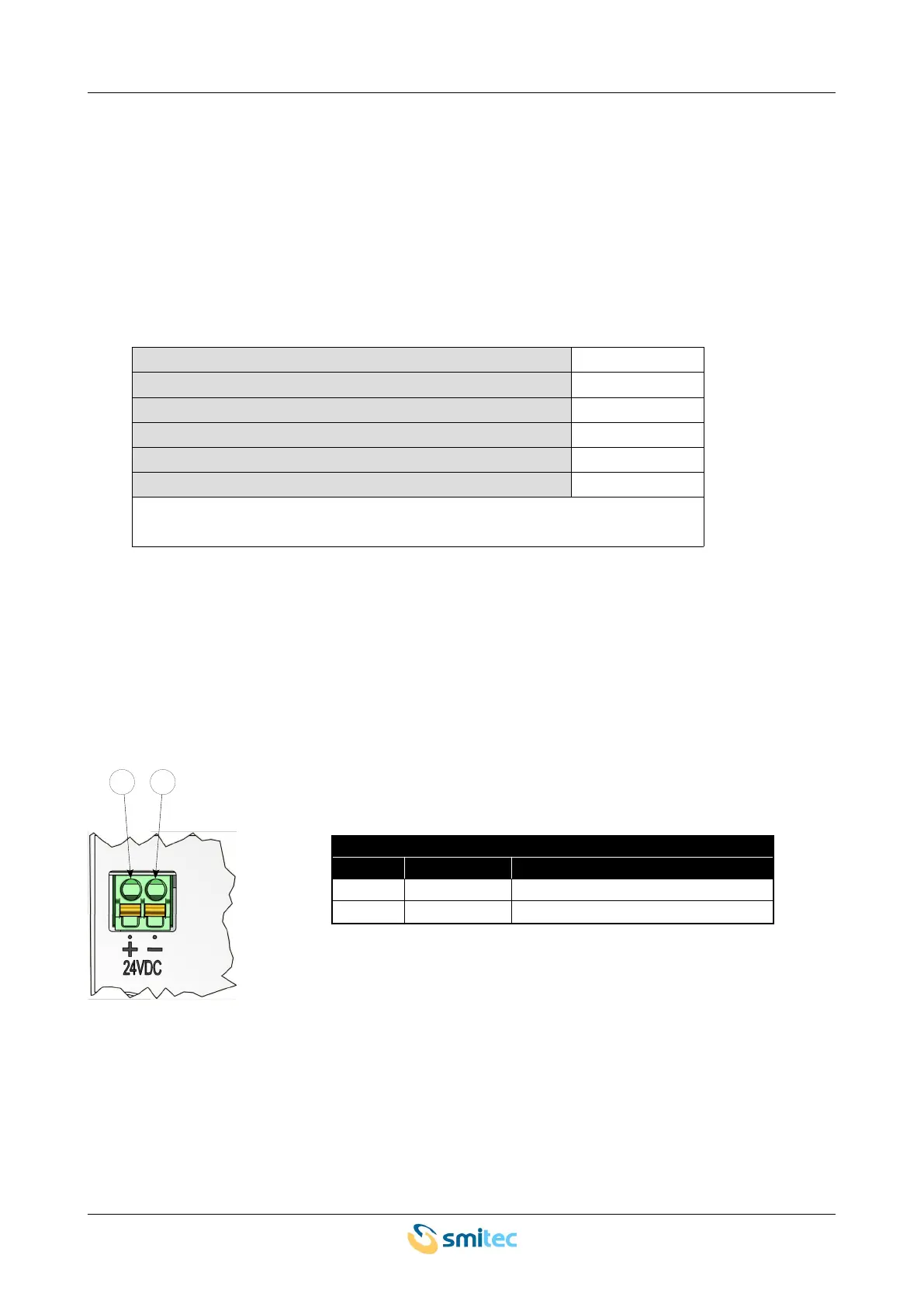

5.7.1 Connections (KZ010374)

This version is equipped with a removable connector for wiring 24V auxiliary power. Here is the pin

configuration of the connector:

24V power supply

pin label signal

1 24VDC + 24VDC power – positive side

2 24VDC - 24VDC power – negative side

Ver. 1.09 SMITECdd 41/74

Loading...

Loading...