Servodrives / inverters series COSMOS 301X Installation, use and maintenance manual - EN

5.7.11 Incremental encoder

An encoder is used as a feedback device for reading and controlling the motor position and speed. These

servo-drives are equipped with a peripheral device that can acquire data from incremental digital encoders,

which are powered by 5 VDC and have differential output signals. Differential outputs offer grater noise

rejection than common single-ended outputs. When brushless motors are used, it is necessary to know also

the rotor initial position; therefore, the encoder must also be equipped with three Hall-effect sensors. The

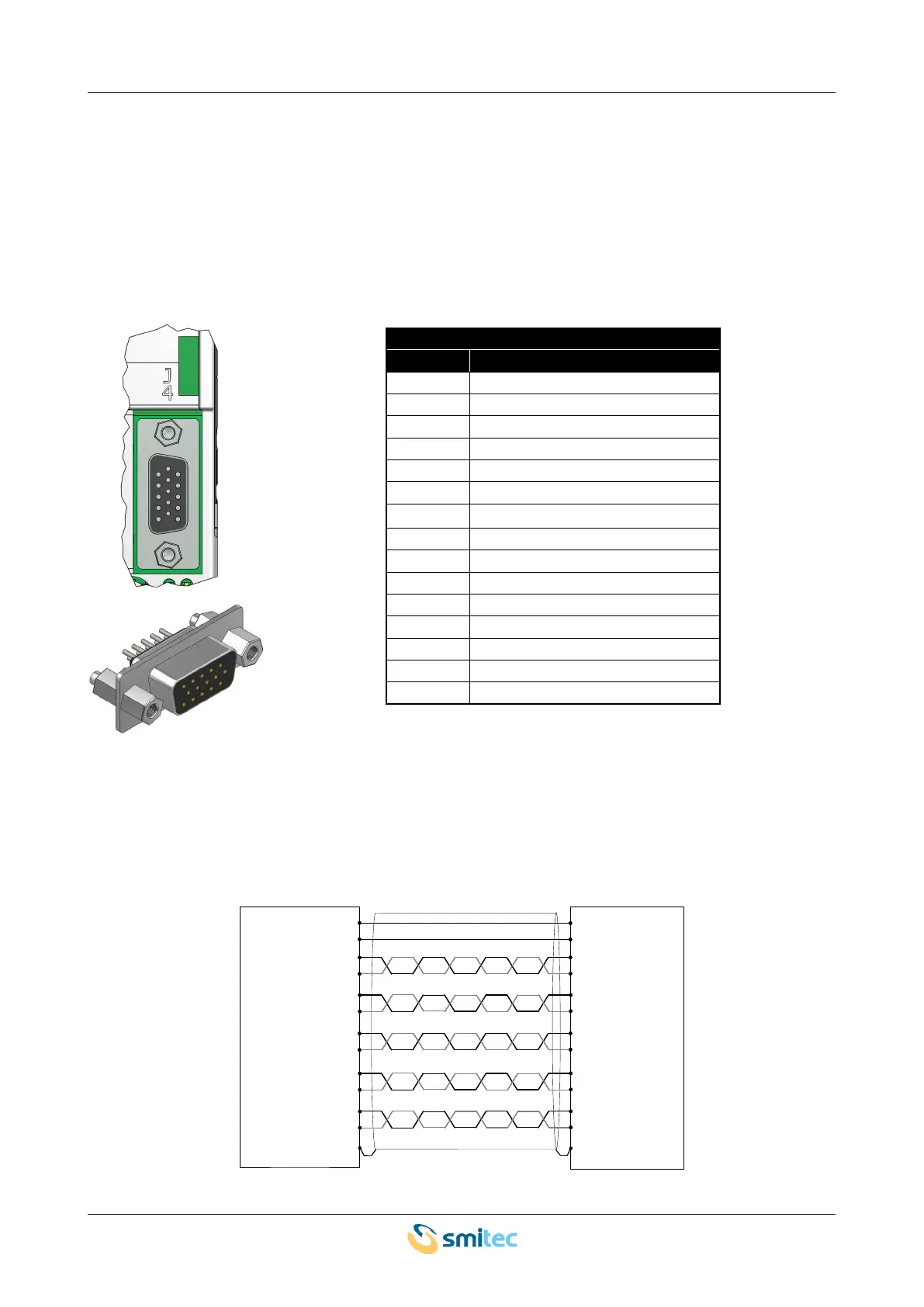

connector used on the encoder is removable; the following picture shows the pin configuration:

Incremental encoder

pin signal

1 Temperature sensor – pin 1

2 Temperature sensor – pin 2

3 +5VDC

4 GND

5 earth

6 A+ channel

7 B+ channel

8 Hall U+

9 Hall V+

10 Hall W+

11 A- channel

12 B- channel

13 Hall U-

14 Hall V-

15 Hall W-

The interface for the Hall sensors is only provided on versions that can also pilot brushless motors. Carefully

check the signal polarity before connecting the encoder; otherwise, the motor might rotate uncontrollably.

Risk of electrical and/or mechanical damage to the system.

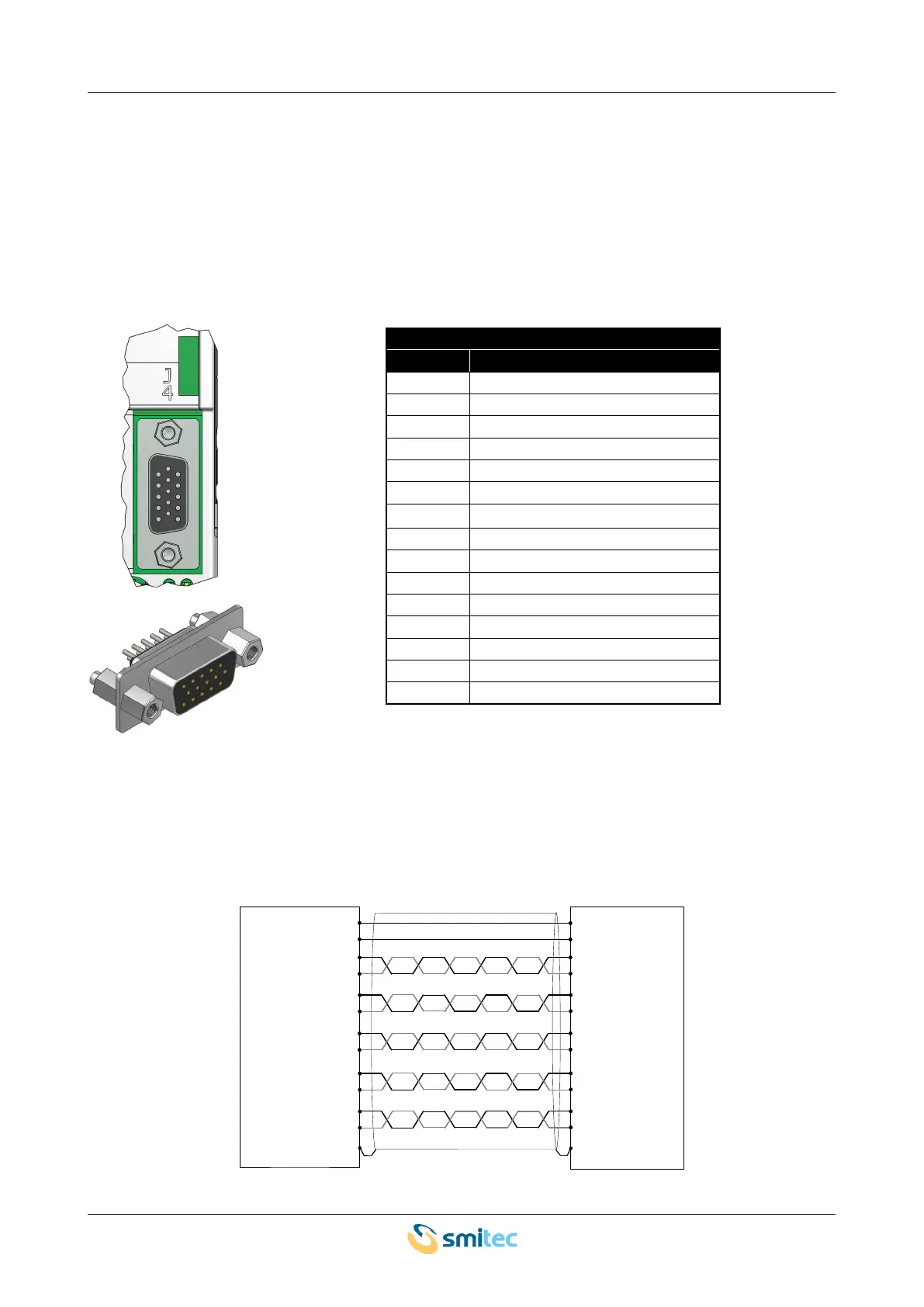

The following picture shows an example of connection; in case of asynchronous motor, the Hall sensors are

not included.

Ver. 1.09 SMITECdd 50/74

Loading...

Loading...