Wire EDM Machine Operation Chapter 10

Copyright November, 98 Page 10-8 Sodick Inc.

The command G83 X005 would load the current X position of the wire into the H005

register.

C

C

O

O

O

O

R

R

D

D

I

I

N

N

A

A

T

T

E

E

S

S

Y

Y

S

S

T

T

E

E

M

M

S

S

H

H

I

I

F

F

T

T

I

I

N

N

G

G

(

(

G

G

5

5

4

4

-

-

G

G

9

9

5

5

9

9

)

)

You know by now that Sodick allows up to sixty different coordinate systems to be used.

These coordinate systems are helpful when you need to run multiple parts in a setup (like

multiple die openings in a progressive die.). But there are also other applications for their

use. Here we take a look at some applications for coordinate system shifting. We will be

using some Q routine techniques, so please be sure you have read the Q routine

descriptions in the beginning of this chapter.

EASILY PROGRAMMING MULTIPLE DIE OPENINGS

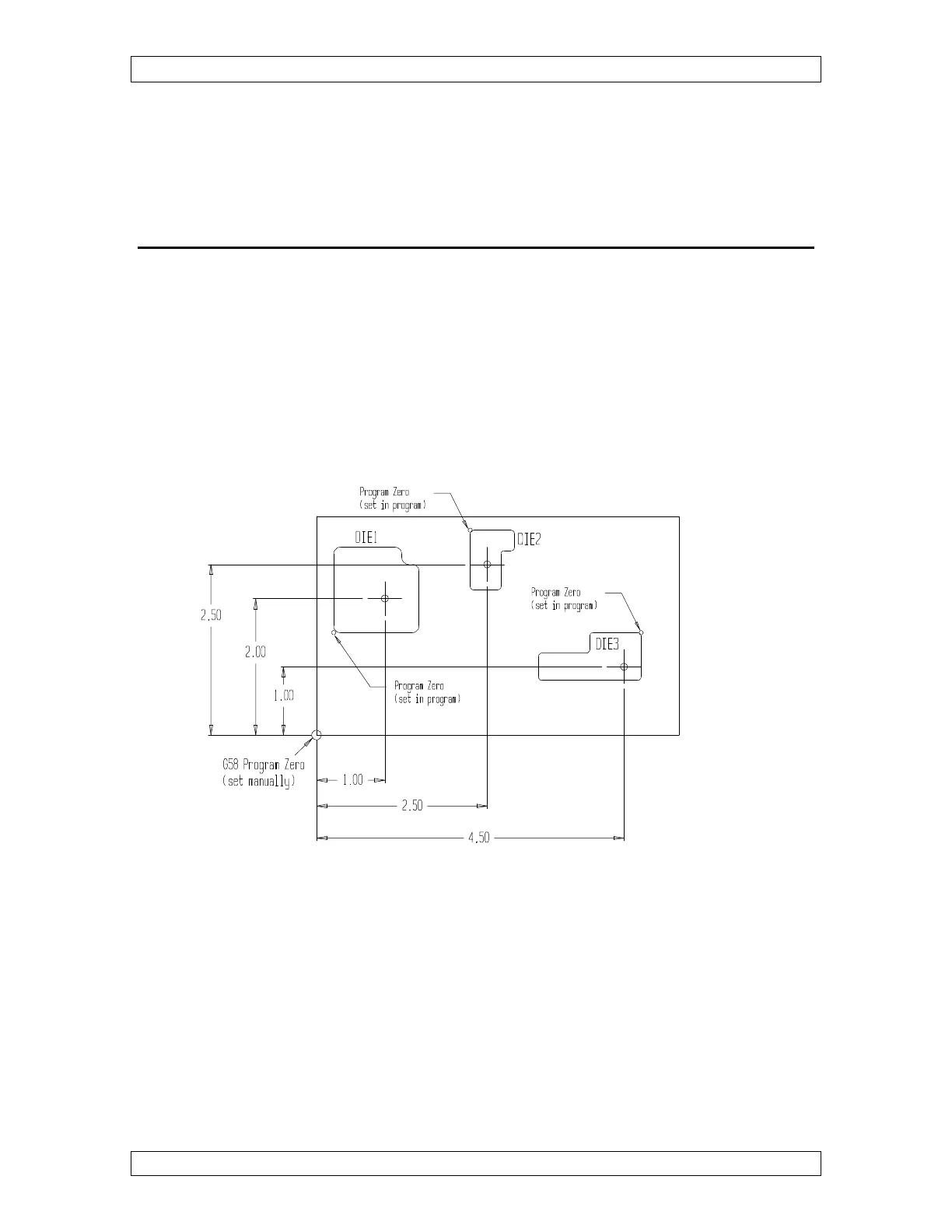

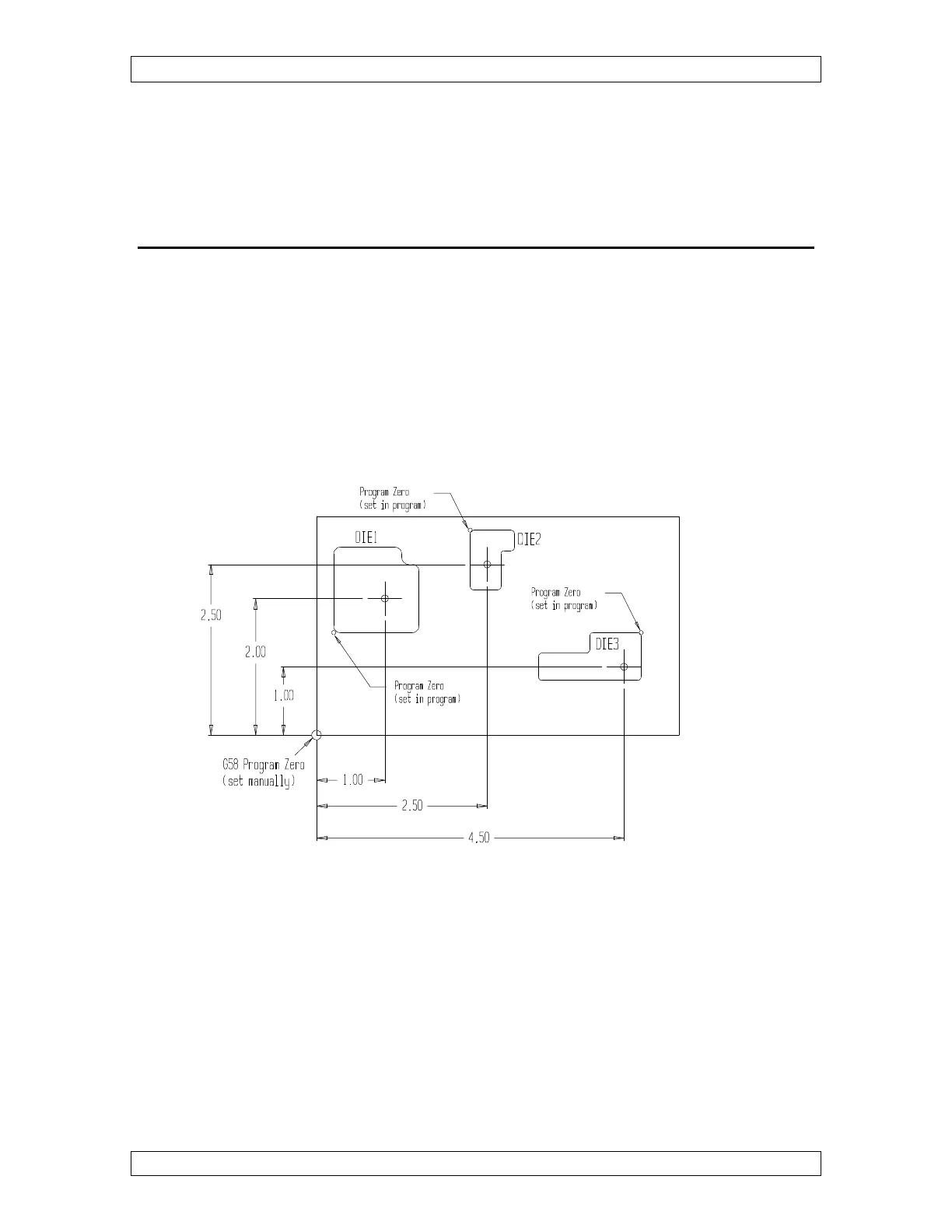

Figure 10-3

One application for coordinate system shifting is when you must cut multiple openings in

a piece of material and you want the program to be automatic. Unless you have an

automatic wire threader, you know that there will be some manual intervention with

mutiple parts (to cut wire and rethread wire for each opening). If you do have a wire

threader, the techniques shown here can help, but and our discussions will assume you do

have a wire threader.

For programming this type of job with an AWT equipped machine, it is recommended

that a CAD / CAM system be used. This is because the CAD / CAM can make the

program to run unattended much easier than manually “Q”ing a series of programs.

Loading...

Loading...