Wire EDM Machine Operation Chapter 15

Copyright November, 98 Page 15-7 Sodick Inc.

E

E

D

D

I

I

T

T

,

,

G

G

R

R

A

A

P

P

H

H

S

S

C

C

R

R

E

E

E

E

N

N

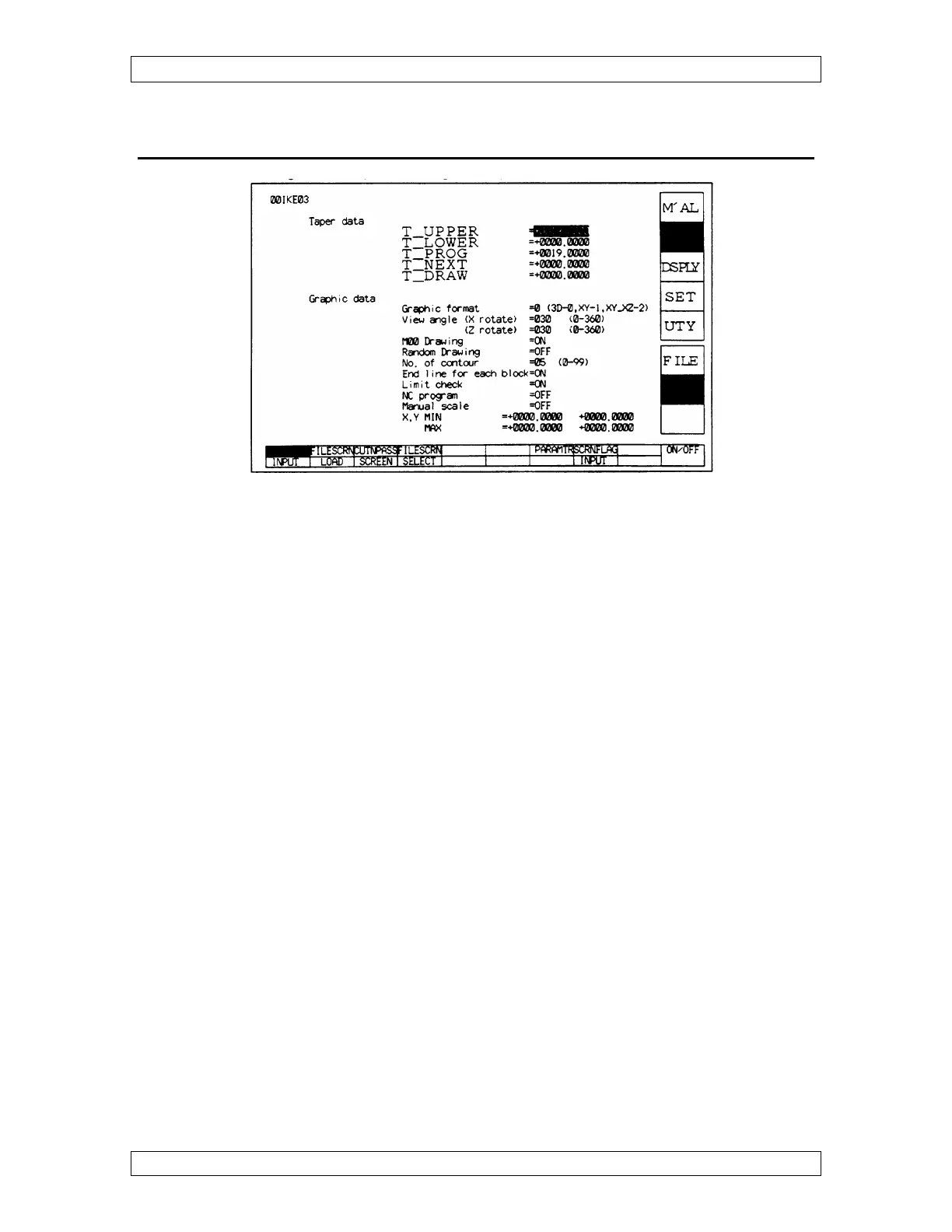

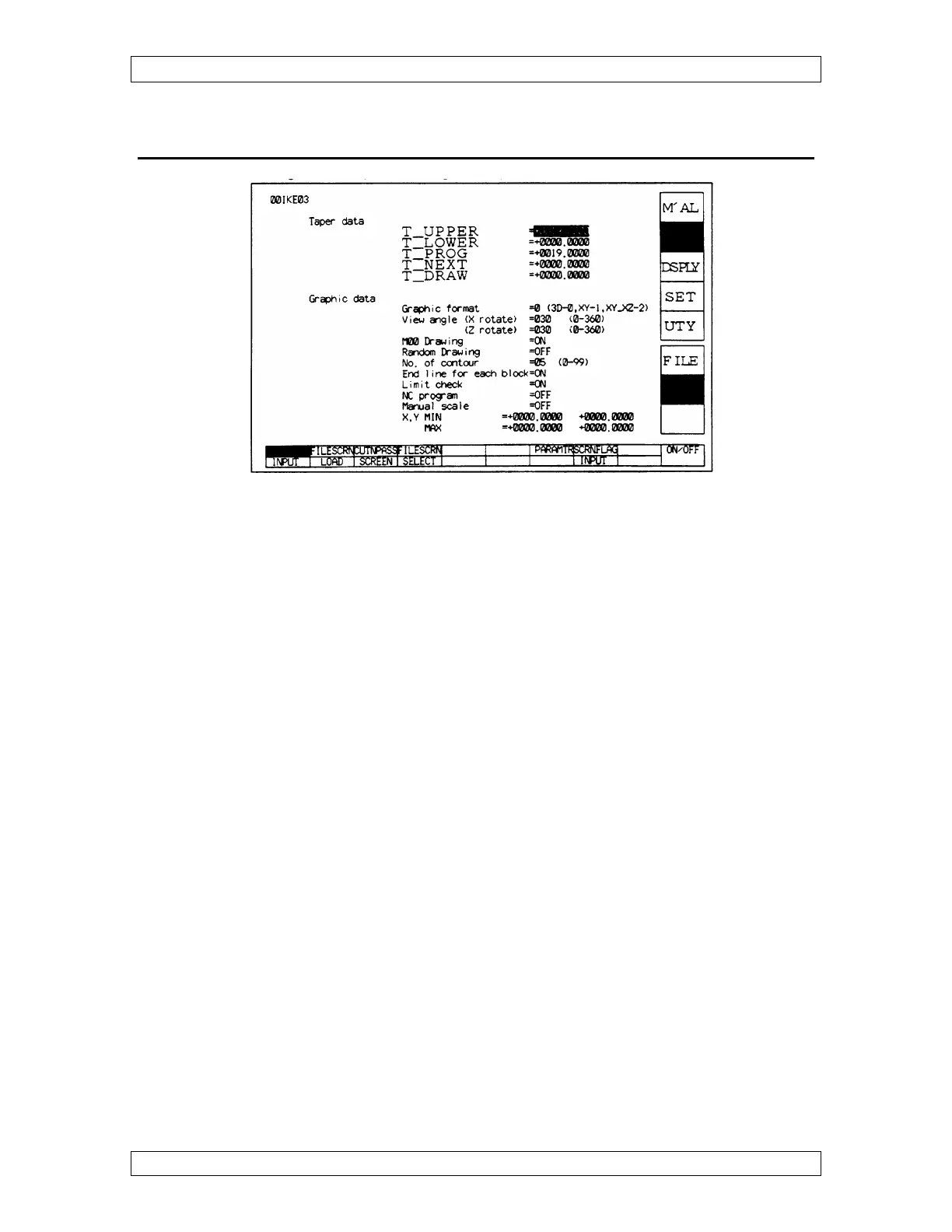

When you go to EDIT, GRAPH, CUT N PASS and you get the error message same data

are set in Taper Data TP & TN, you will have to enter either 0 or Workpiece Thickness

in table to Next under Taper Data when in Graphics. Now try to do a CUT N PASS

again.

NOTE: Graphics drawing will show the TOP of the part as BLUE, and the

BOTTOM of the part as GREEN.

GRAPHIC FORMAT: Choose 0 for 3D, 1 for Top view or 2 for a Front & Top view.

VIEW ANGLE: Usually both X rotate and Z rotate at 30°. This specifies the angle of

rotation of Graphics in X & Z axis, when in 3D.

M00 DRAWING: Shows where your stop is located when ON.

RANDOM DRAWING: When in 3D, it shows only a single plane, usually OFF.

NO. OF CONTOURS: When in 3D, how many slices through thickness of part. This

controls the resolution of the picture.

END LINE FOR EACH BLOCK: When on, the graphics drawing will show red lines

at the end of each block of NC .

LIMIT CHECK: When ON, it will tell you if the machine will hit a limit switch, when

running the program. This does not replace dry run. Remember to be at the start point

before graphing the program.

Loading...

Loading...