Wire EDM Machine Operation Chapter 6

Copyright November, 98 Page 6-8 Sodick Inc.

G74 (4 axis) PROGRAMMING “U” or “V” Values: U or V axis values are incremental

from the X Y values, in absolute from it’s present position.

DECMAL POINTS: The control will accept decimal points, and is preferred, but not

mandatory.

TRAILING ZERO’S: Trailing zero’s after the output value, when using decimal points,

are not required. EX “G02 X.1 Y.12 I.123 J.1234”.

N

N

C

C

P

P

R

R

O

O

G

G

R

R

A

A

M

M

E

E

X

X

A

A

M

M

P

P

L

L

E

E

S

S

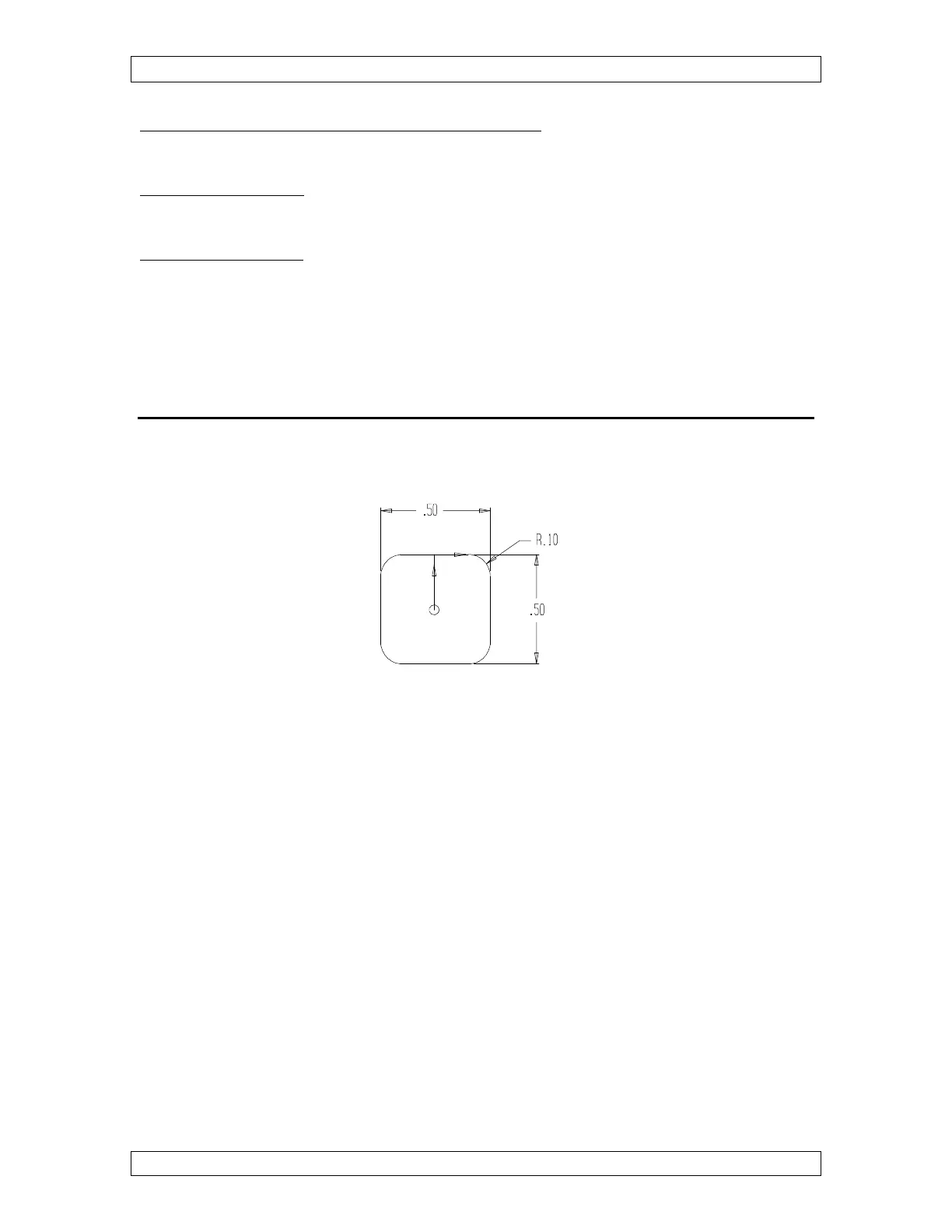

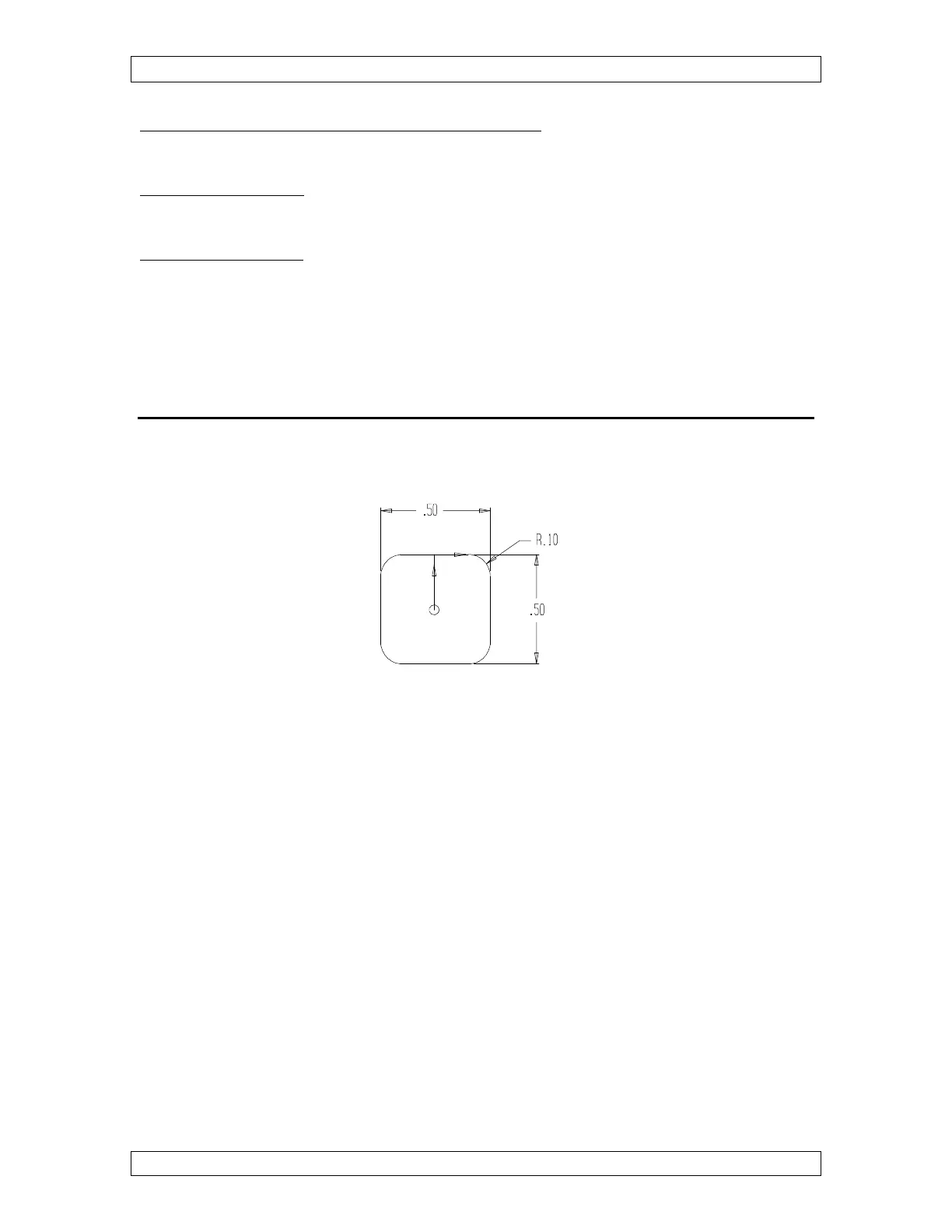

PROGRAM EXAMPLE 1

The below program is an example to make a .500” square, with .100” corners. The

approach is at a right angle to the contour, and starts at X0 Y0.

N0001;

N0002 G54 G90

N0003 G92 X0. Y0. G29

N0004 T84 (High Flush)

N0005 T94 (Submerged)

N0006 C451 (Cutting Condition)

N0007 G42 H082 (Offset Right, .0082”)

CRT(JOB 1 CNT2X ROUGH CUT FORWARD)

N0008 G52 A.5000 G01 Y.25 (Taper Right, .500 Degree)

N0009 X.15

N0010 G02 X.25 Y.15 I0. J-.1

N0011 G01 Y-.15

N0012 G02 X.15 Y-.25 I-.1 J0.

N0013 G01 X-.15

N0014 G02 X-.25 Y-.15 I0. J.1

N0015 G01 Y.15

N0016 G02 X-.15 Y.25 I.1 J0.

N0017 G01 X-.1

N0018 X0.

N0019 G50 A0. G40 Y0. (Cancel Offset and Taper)

Loading...

Loading...