Wire EDM Machine Operation Chapter 3

Copyright November, 98 Page 3-4 Sodick Inc.

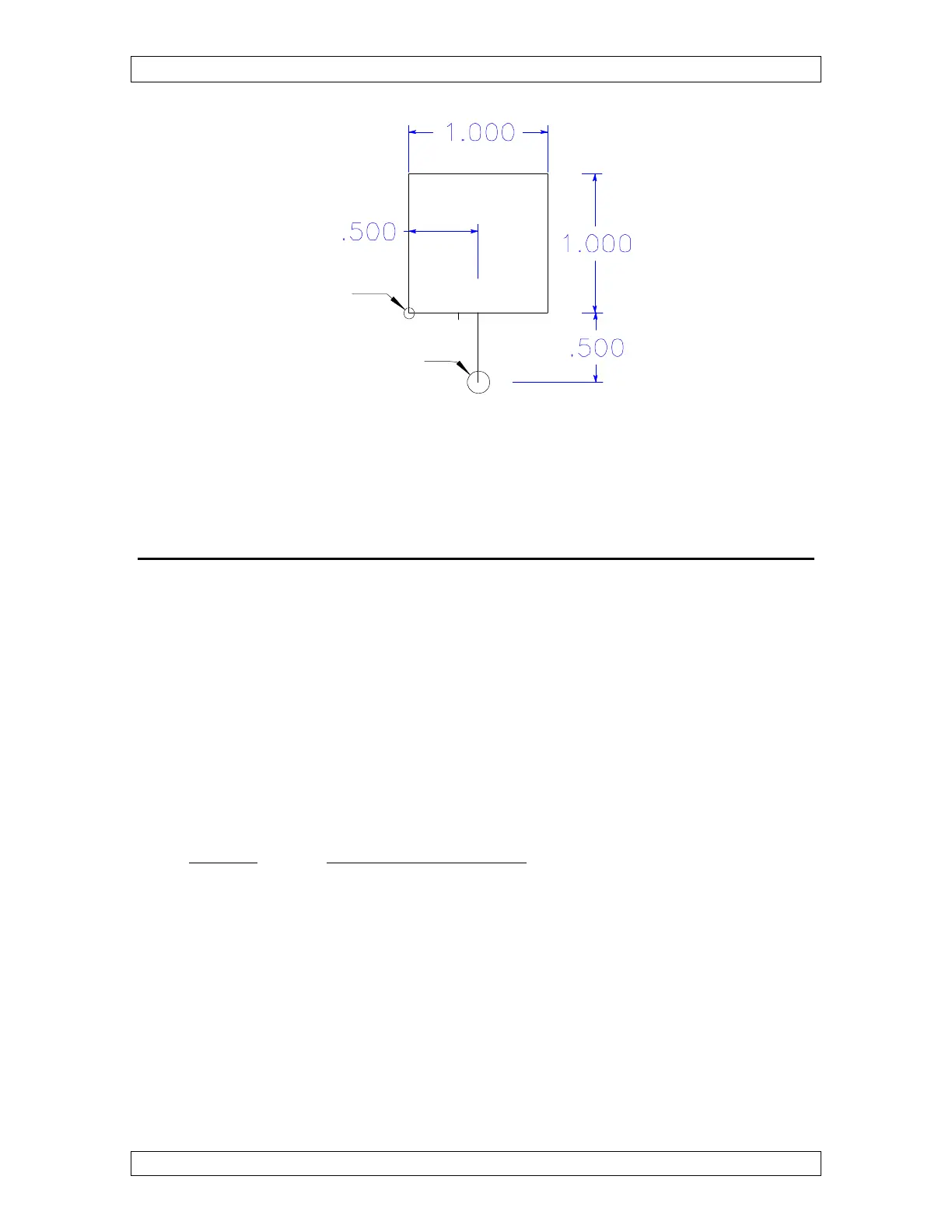

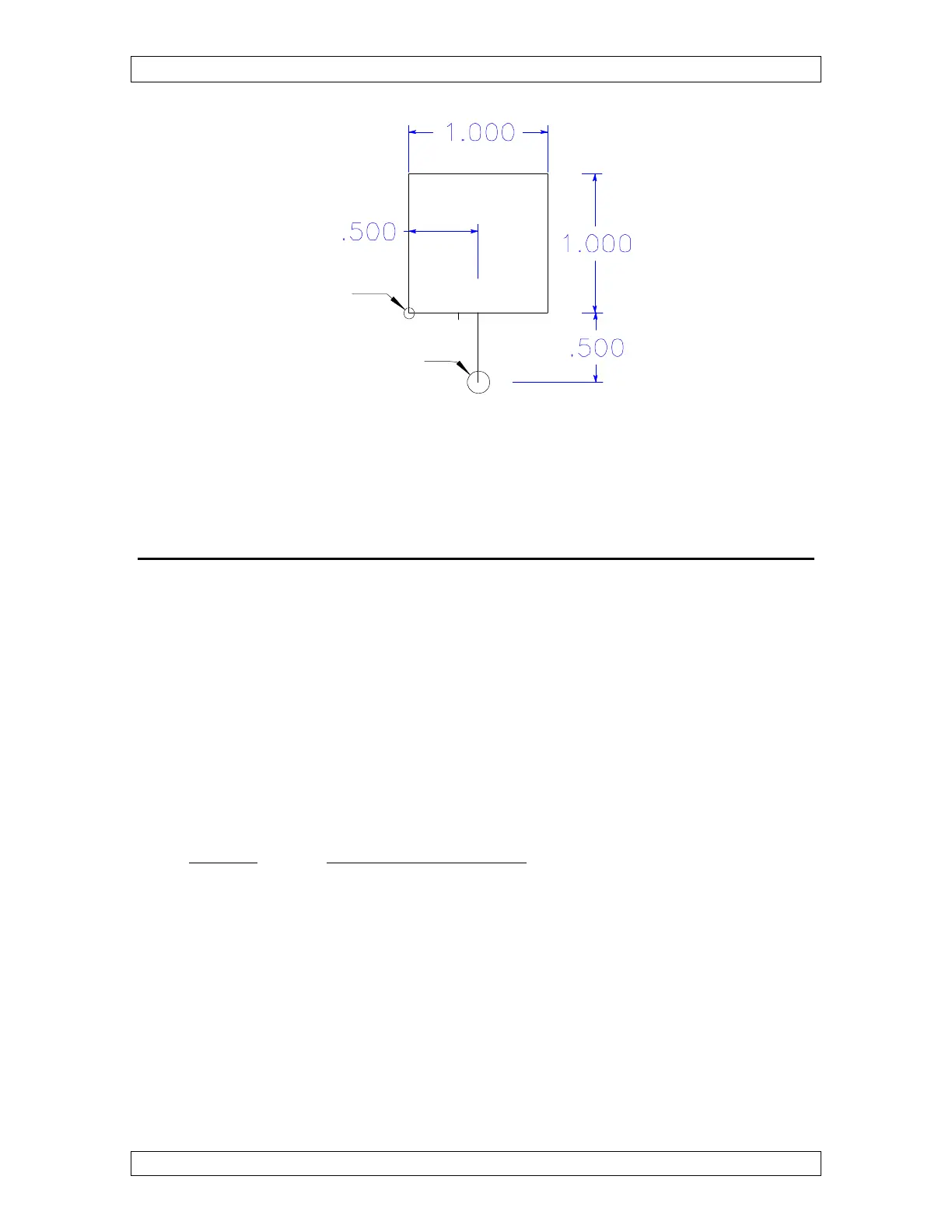

Figure 3-4

U

U

N

N

D

D

E

E

R

R

S

S

T

T

A

A

N

N

D

D

I

I

N

N

G

G

W

W

O

O

R

R

K

K

C

C

O

O

O

O

R

R

D

D

I

I

N

N

A

A

T

T

E

E

S

S

C

C

R

R

E

E

E

E

N

N

S

S

Sodick allows you to assign up to sixty (60) different program zero points. This could be

helpful when you are machining multiple parts. However, most of the time you will only

be interested in one of the available work coordinate screens. You will usually start with

coordinate system number zero, which is commanded by a G54. If you are setting up

more than one part at the same time or cutting multiple openings in a part, you might be

commanding other work coordinate screens other than number zero.

Prior to programming your G92 you can tell the control which coordinate system you

want to work in. This means that you can include a G code in the program PRIOR to the

G92 command.

Here is a list of all of the coordinate systems available

G CODE DISPLAY AT MACHINE

G54 to G59 = work coordinates A00 to A05

G154 to G159 = work coordinates A10 to A15

G254 to G259 = work coordinates A20 to A25

G354 to G359 = work coordinates A30 to A35

G454 to G459 = work coordinates A40 to A45

G554 to G559 = work coordinates A50 to A55

G654 to G659 = work coordinates A60 to A65

G754 to G759 = work coordinates A70 to A75

G854 to G859 = work coordinates A80 to A85

G954 to G959 = work coordinates A90 to A95

Progam Zero

Start Point

N0005 G92 X.500 Y-.500

Loading...

Loading...