Wire EDM Machine Operation Chapter 12

Copyright November, 98 Page 12-1 Sodick Inc.

C

C

H

H

A

A

P

P

T

T

E

E

R

R

1

1

2

2

M

M

A

A

I

I

N

N

T

T

E

E

N

N

A

A

N

N

C

C

E

E

Sodick Wire EDM’s are precision machine tools and should be treated as such.

Preventative maintenance will eliminate unnecessary problems, downtime, and

aggravation and should be performed on a regular basis religiously. Sodick Wire EDM’s

had a reputation in the industry to run longer and in dirtier conditions between

maintenance intervals than their competitors. This does not mean maintenance is not as

important and should be put off until you start having problems with the machine. "Don’t

fix it if it ain’t broke" theory doesn’t apply here. Ideally, the machine should be located in

an environment where the air is clean (not right next to a grinder) and temperature

doesn’t fluctuate more than several degrees (not located in direct sunlight or by air duct,

etc.)

NOTE: To remove the EDM residue that accumulates on the machine and on the

workpieces, cleaners that contain phosphoric acid, hydrogen chloride or equivalent are

needed. Toilet bowl cleaners SNO-BOL and ALLOUT work well. AC-500 is a cleaner

that works well and is not as harsh as toilet bowl cleaners (1-800-842-3919). These

cleaners should be rinsed off within several minutes with water and will decrease the life

of the DI resin if too much of it gets into the system.

D

D

I

I

S

S

P

P

L

L

A

A

Y

Y

M

M

A

A

I

I

N

N

T

T

E

E

N

N

A

A

N

N

C

C

E

E

S

S

C

C

R

R

E

E

E

E

N

N

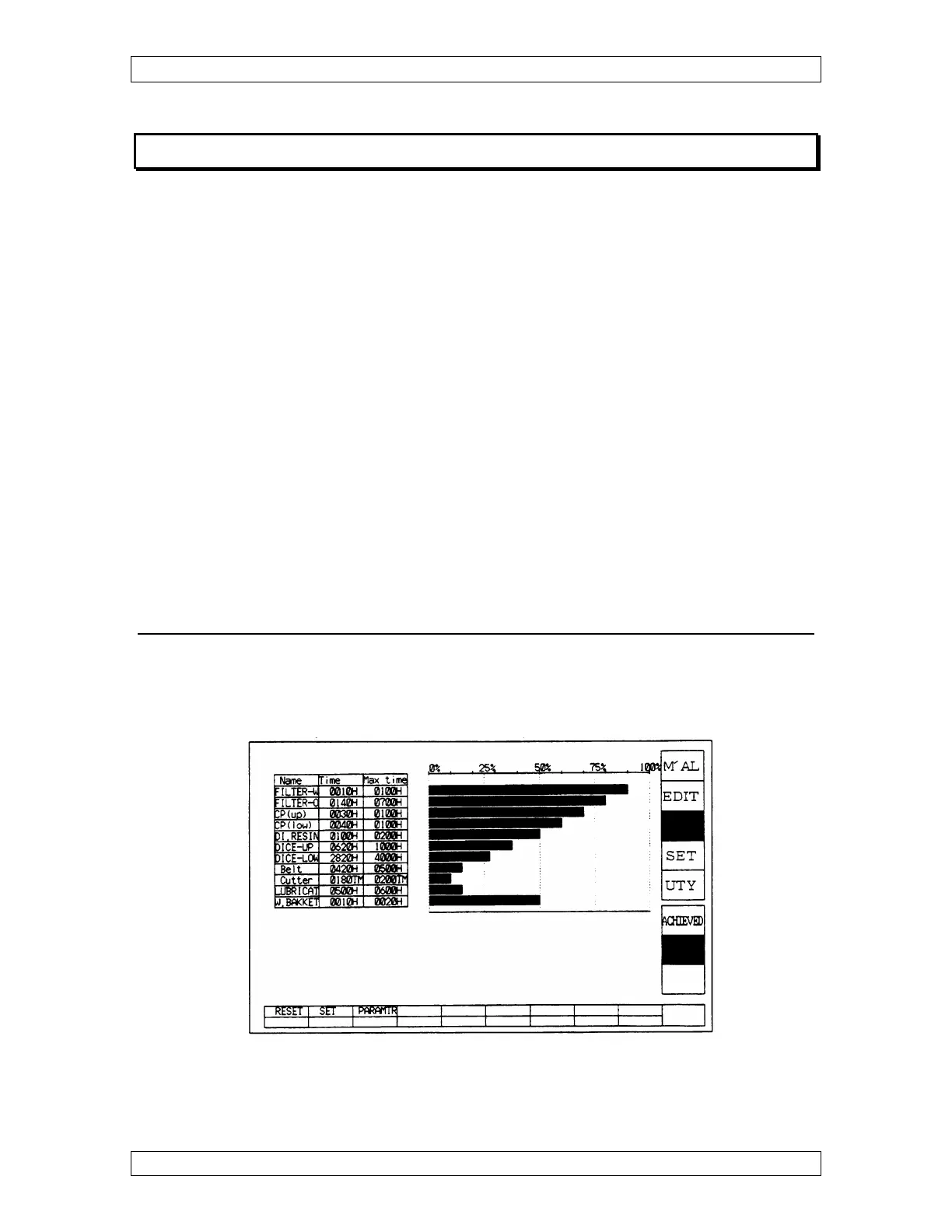

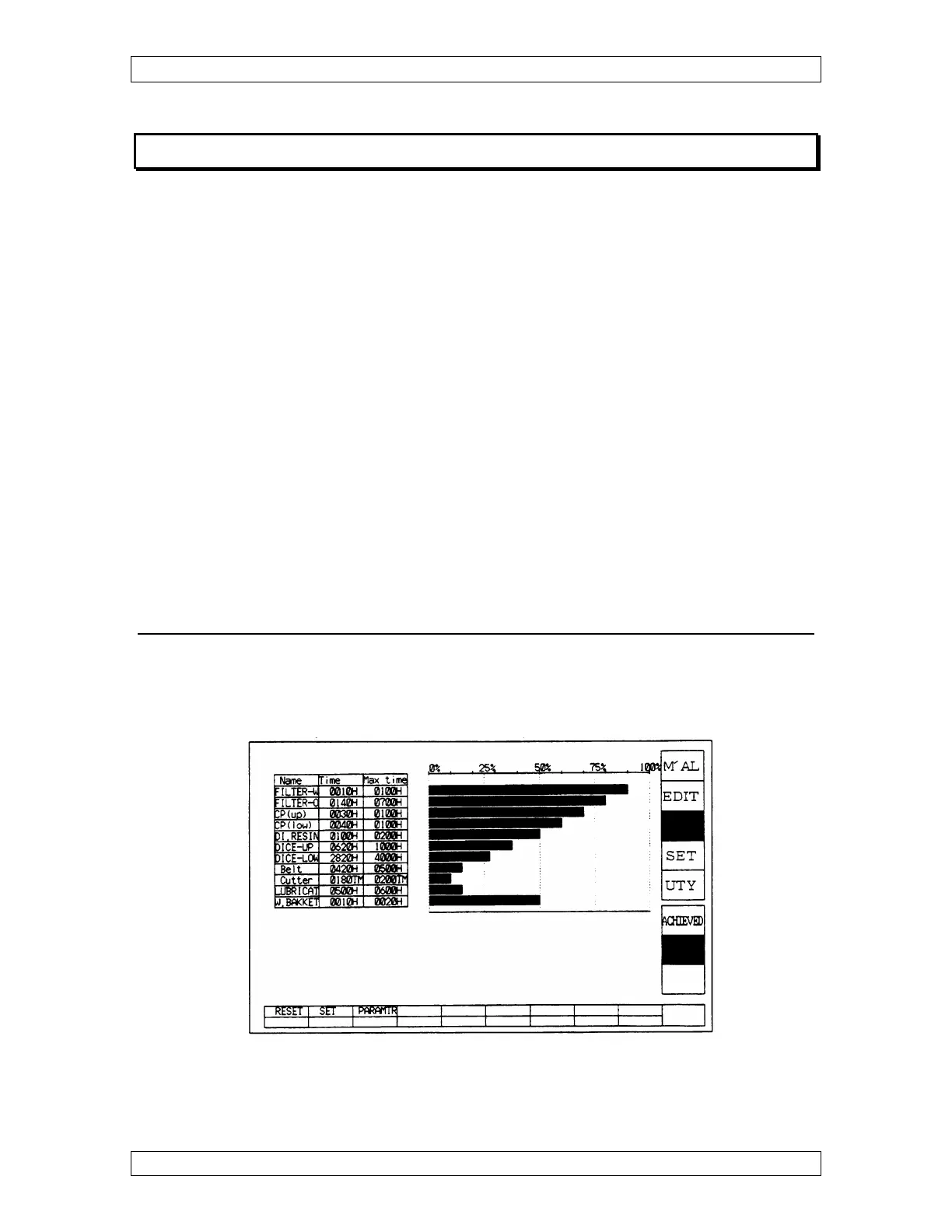

In the “DSPLY” “MENTE” screen (figure 12-1), there is a bar graph that will turn red

when the item is due for service. It can be reset after an item has been serviced, returning

the bar graph to 100% and green. The setting for “MAX TIME” is adjustable, and should

be set to a value. The value “TIME” displays the machining hours that the item has.

Figure 12-1

Loading...

Loading...