Wire EDM Machine Operation Chapter 12

Copyright November, 98 Page 12-15 Sodick Inc.

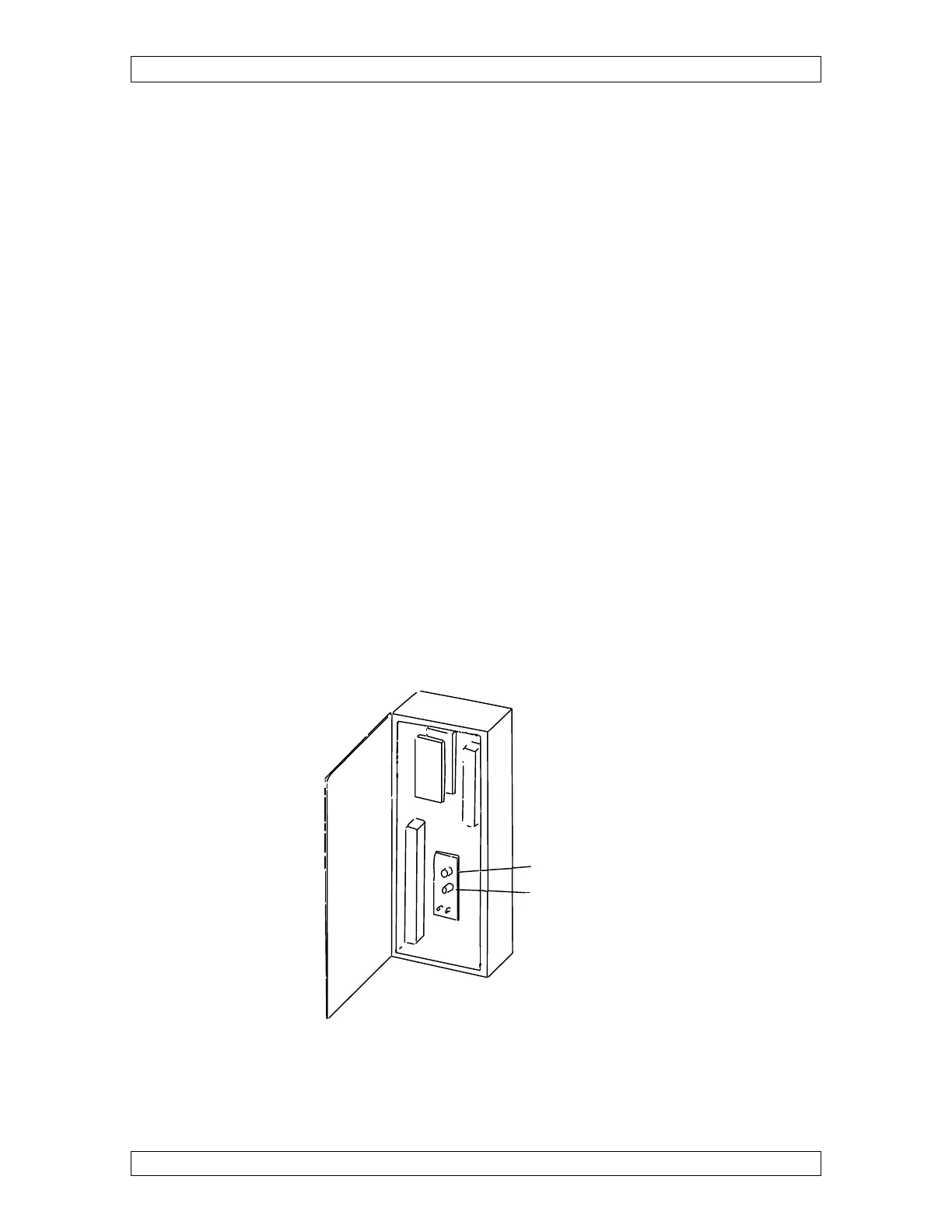

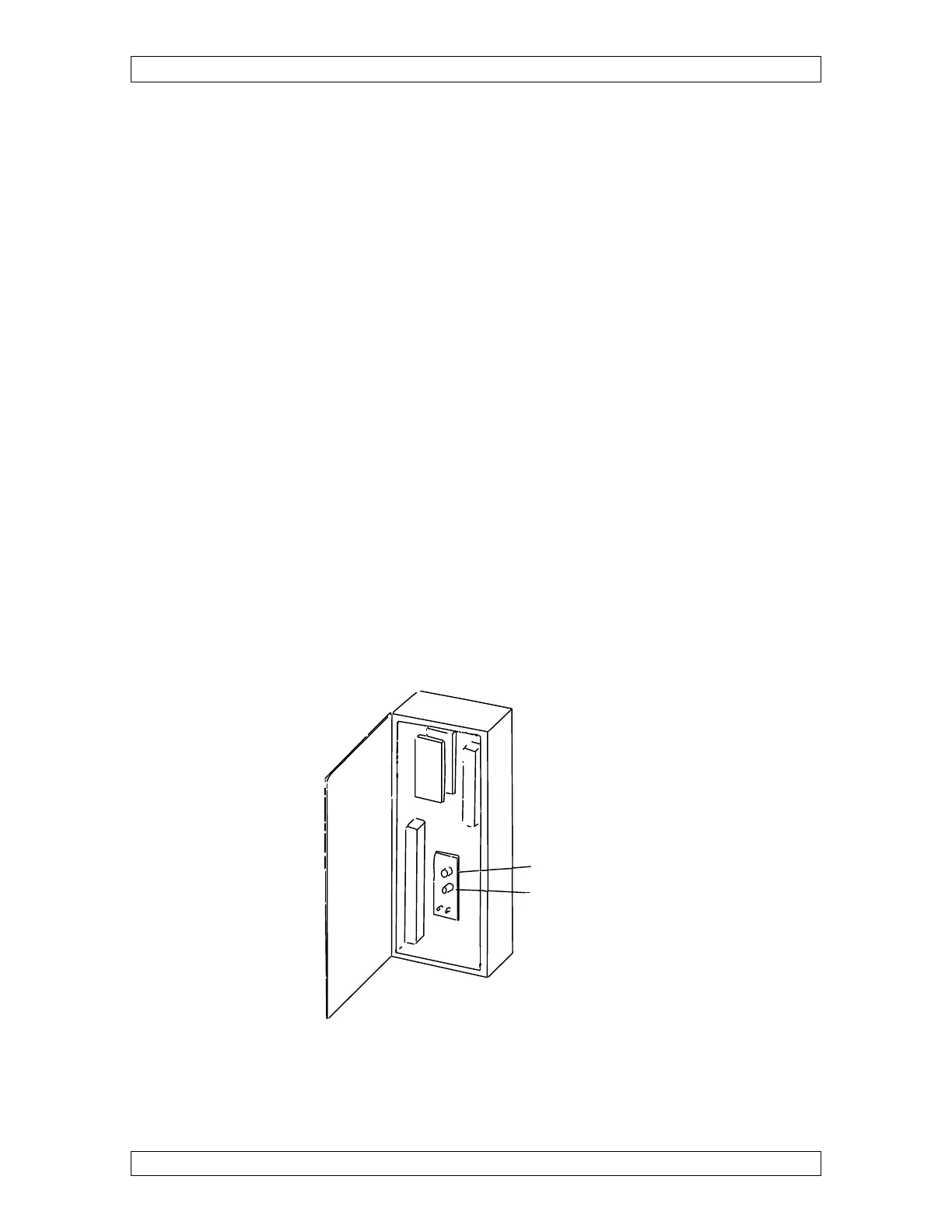

ELECTRICAL CABINET SETTINGS A320D,A530D

There are 4 settings available in the electrical cabinet located behind the machine tool.

These affect how the wire spool shaft, and AWT operate.

Wire Rewind: Set between 70 and 80

When the wire breaks, the AWT unit must rewind the broken wire above the upper guide.

A larger wire spool requires it to be set to a higher number.

Wire Bobbin Brake: Set between 30 and 40

This is the reversing torque on the wire spool. This reversing keeps the wire from

unspooling itself if the wire is stopped or broken. A larger wire spool requires a higher

setting.

Speed control Sensing VR Knob : Set to 30.

This sets the sensitivity of the buckling sensor on the AWT unit. A lower setting makes it

more sensitive to the wire buckling. Set it lower if the AWT drive rollers don’t rewind

the wire if it buckles between the drive rollers and the water jet pipe.

Speed Control Unit: Set to 11 or 12 o’clock position.

This orange knob controls the speed of the drive rollers and the AWT pipe speed on the

AWT unit. Setting it further clockwise makes the drive rollers feed the wire faster when it

is threading the wire. This unit is not installed on A320 machines.

If you adjust the speed of this unit, also adjust the parameter AWT 2 FEED TIME (SEC)

0

0

r

BB2

0

Loading...

Loading...