Wire EDM Machine Operation Chapter 8

Copyright November, 98 Page 8-5 Sodick Inc.

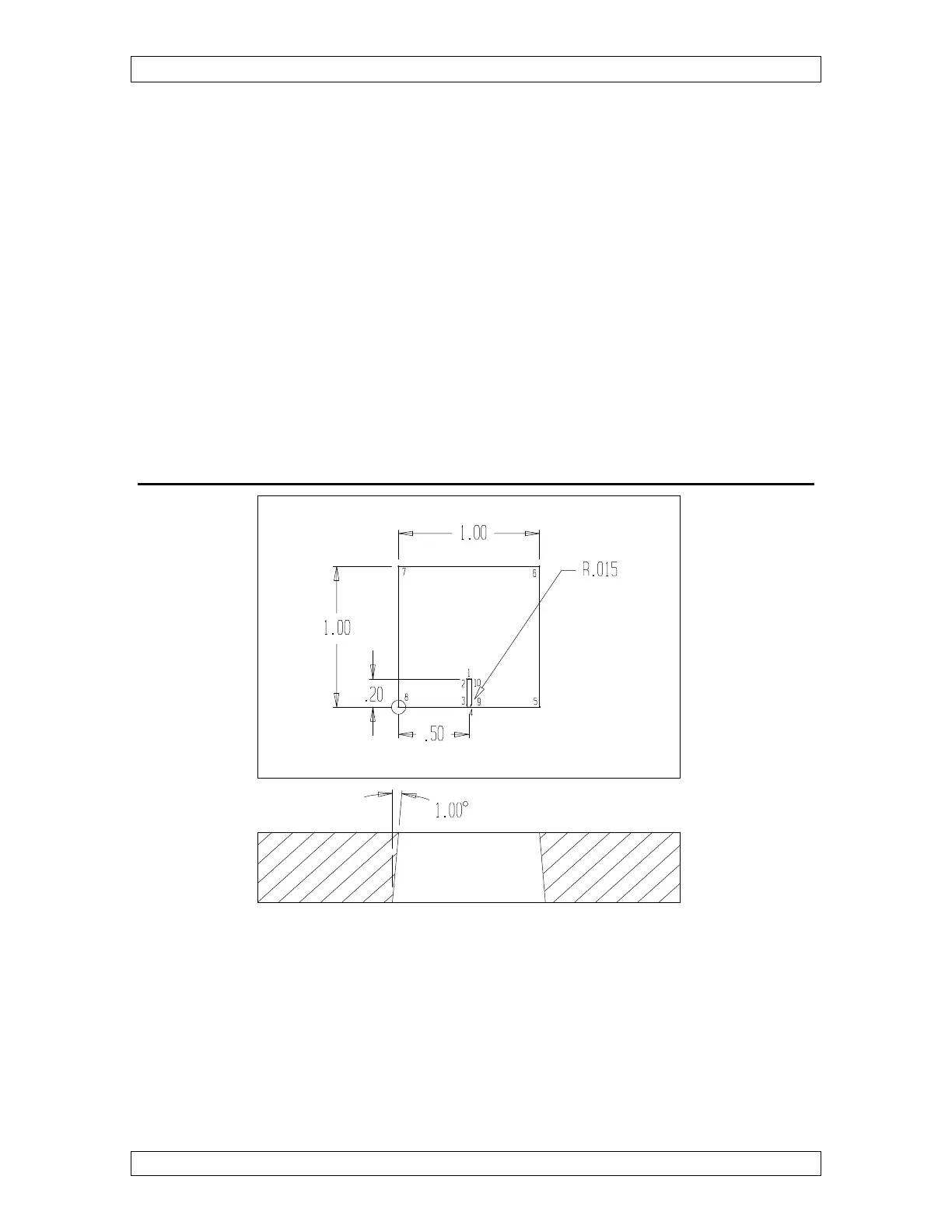

maximum possible taper angle on your particular machine based on part thickness. The

thinner the workpiece, the greater the taper angle can be.

To initialize taper properly, you simply program the G51 (left) or G52 (right) in a

command with the “A” word. Then move to the first surface you wish to machine with

taper. The control will initiate the taper DURING the movement to the first surface to

cut.

Once initialized correctly, the taper cutting commands will cause the wire to maintain the

proper angle around all coordinates programmed.

After all the cutting movements have been made, you MUST remember to cancel taper

cutting (with a G50 command). The control will bring the wire back to vertical during the

next X and or Y movement.

E

E

X

X

A

A

M

M

P

P

L

L

E

E

O

O

F

F

H

H

O

O

W

W

T

T

O

O

P

P

R

R

O

O

G

G

R

R

A

A

M

M

T

T

A

A

P

P

E

E

R

R

C

C

O

O

R

R

R

R

E

E

C

C

T

T

L

L

Y

Y

:

:

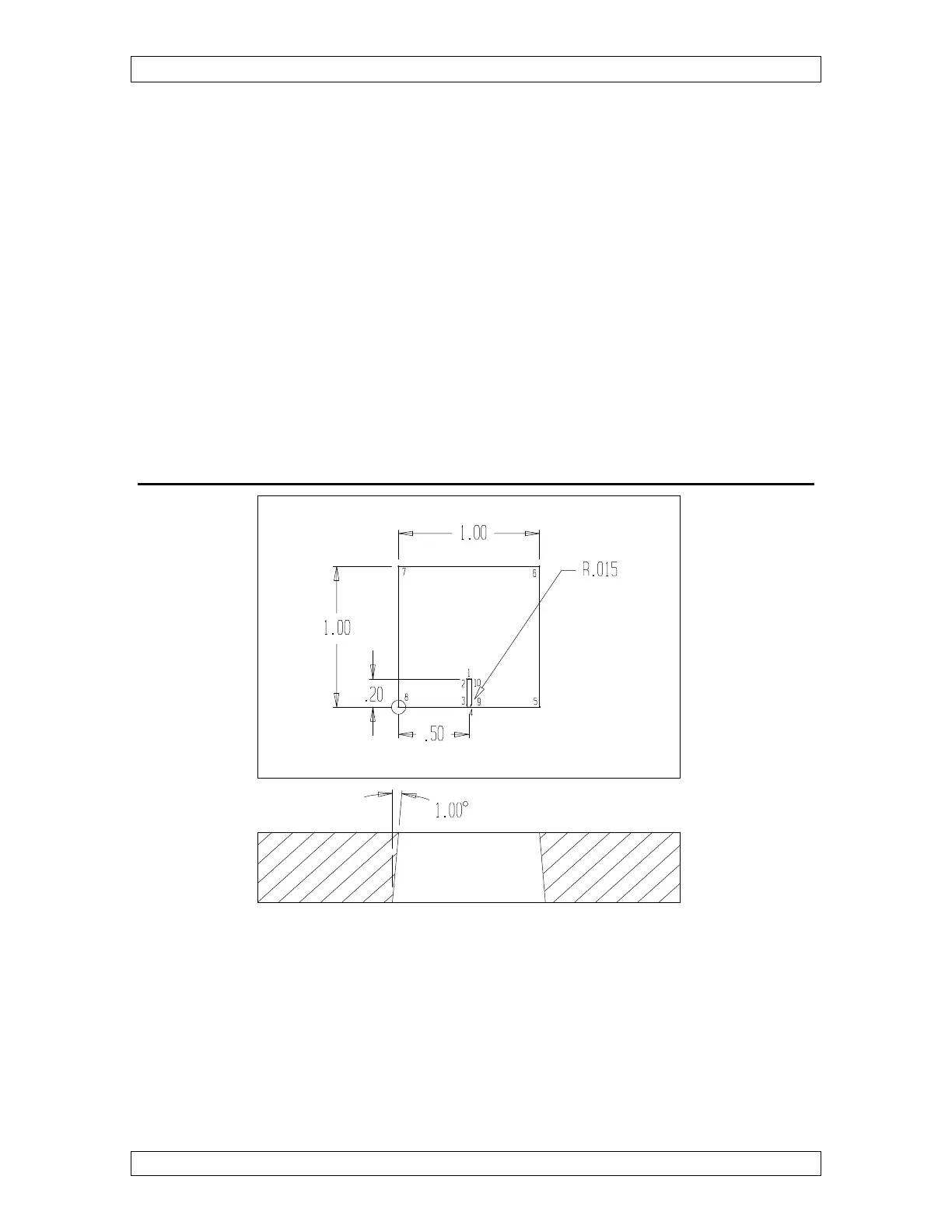

Figure 8-2

NC program for figure 8-2

N005 G54 (SELECT COORDINATE SYSTEM)

N010 G92 X.5 Y.2 (SET PROGRAM ZERO)

N015 G90 (ABSOLUTE MODE)

N020 G41 H061 (LEFT OFFSET OF .0061)

Loading...

Loading...