Operation 4

General commissioning

Battery maintenance

As the energy provider, the battery must be

treated with due care and attention!

Therefore:

– Keep the battery clean and dry.

– Charge the battery regularly.

– Ensure that the cable conne

ctions and

battery female connector a

re in good

working order.

– Apply acid-free battery grease to protect the

connections from corrosion.

– Store batteries only when charged.

In addition for batterie

s with liquid electrolyte:

– Check the electrolyte level regularly.

– Siphon off spilt electrolyte from the battery

tray using a siphon.

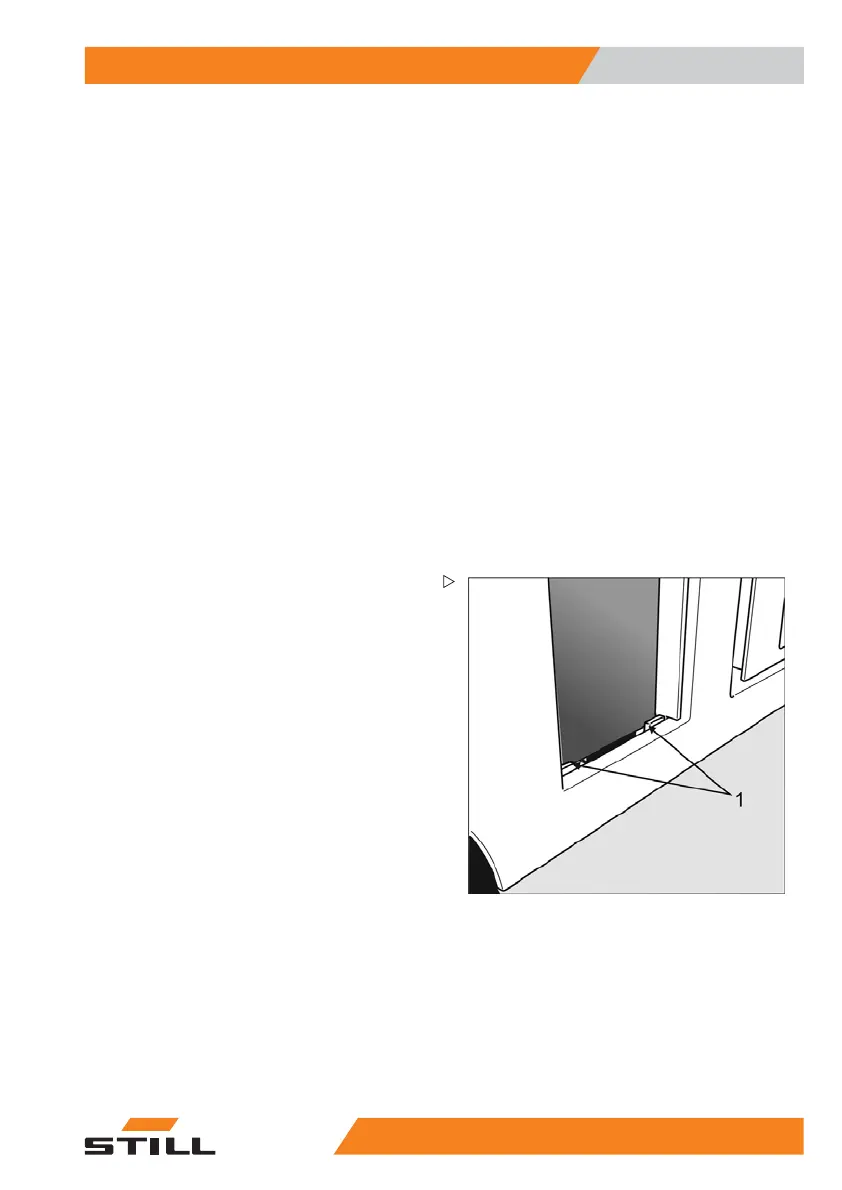

Replacing the battery

On this industrial truck, the battery is replaced

to the side. Only suitable aids such as lifting

gear and battery change frames may be used

for this purpose.

In the standard des

ign, the battery rests in a

recess (1). The ba

ttery should be replaced

using a forklift t

ruck.

The forklift truc

k used must be suitable for this

purpose.

• The fork must be of sufficient length for the

existing load centre of gravity.

• The load capacity must correspond to the

weight of the battery fitted.

• The external width

the fork must be adjusted

to the insertion ope

ning.

• Adjust the fork tilt such that when you

remove the battery it does not come into

contact with the industrial truck.

• The battery is not provided with a latch.

521

2 804 3001 EN - 02/2017 47

Loading...

Loading...