Istruction Manual for Operation and Maintenance SPX-960:

WARNING

When this button is pressed (34 in Fig. 31), the hook and

lifted load fall down freely (uncontrolled). This is why the

button must be used in serious emergency cases when

the risk exists that the machine tips over.

Make sure that free fall is compliant with the standards

and regulations existing in the country where the machine

is operated.

35) Anti-tipping system bypass key (Fig. 35 and 31). Turn

this key to override the safety functions of the anti-tipping

system.

WARNING

Utilize the bypass key functions only in real emergency

cases being fully aware of lifting operations.

In these conditions, in fact, the machine stability is not

controlled by the anti-tipping system.

37) Anti-tipping system power switch (Fig. 36 and 31). Turn the

switch to supply power to the anti-tipping system.

38) White light - electric system error (37 Fig. 31). This light

indicates that an electric error has occurred.

39) Yellow light - anti-tipping alert (38 Fig. 31). This light goes

on during lifting operations 15% before the max. lifting

capacity is reached (see yellow curve in the lifting capacity

diagram on page 15).

Red light . anti-tipping alarm (38 Fig. 31). This light goes on

during lifting operations 15% before the max. tipping curve

is reached (see red curve in the lifting capacity diagram

on page 15). This light is usually accompanied by a sound

signal (buzzer).

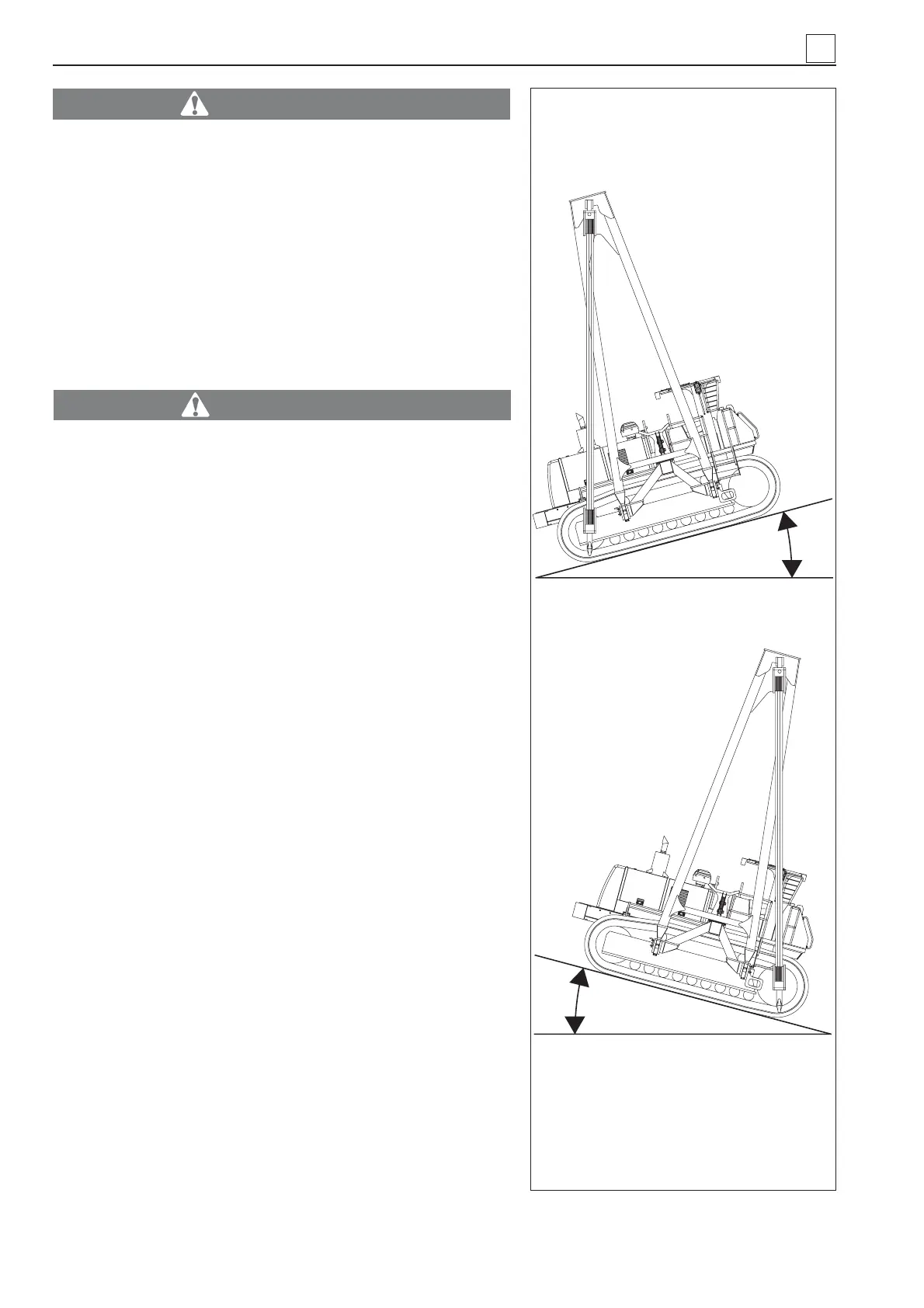

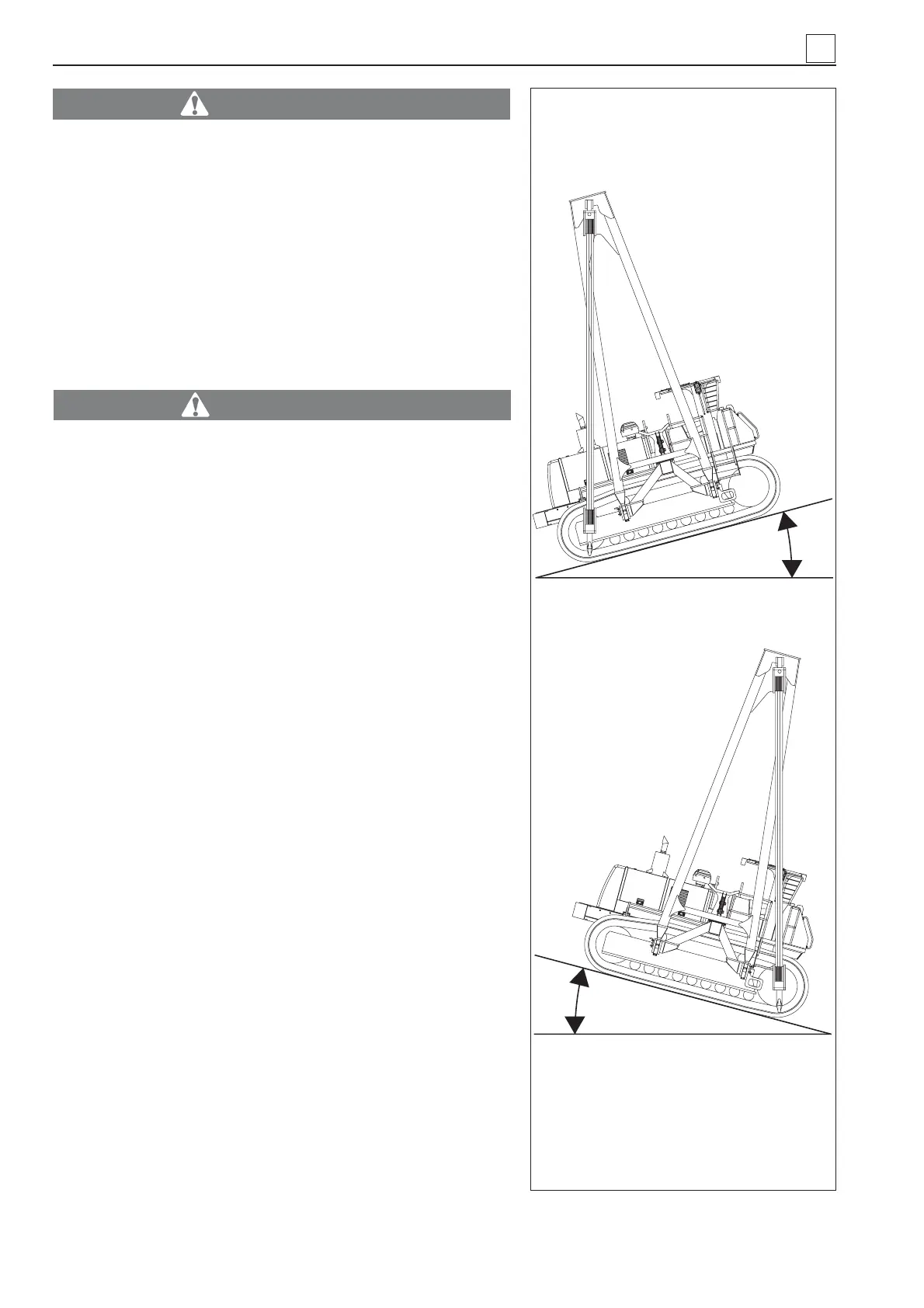

39) Longitudinal Alarm System (LAS) . longitudinal stability

indicator (39 Fig. 31). A number of green, red and yellow

LEDs turn on in this sequence depending on how seriously

affected machine longitudinal stability is.

This red lights are usually accompanied by a warning sound

signal (buzzer). This means that in this position the vertical

line of the hook is outside the machine support area (Fig.

32).

40) Buttons for setting control unit (40 Fig. 31).

4

Fig. 32

12°

12°

4-12

MACHINE OPERATION

Loading...

Loading...