1G-10 Fuel System:

Fuel Cut Valve Inspection

B705H11706004

Inspect the fuel cut valve in the following procedures:

1) Remove the fuel cut valve. Refer to “Fuel Drain Tray

and FTPC Valve Removal and Installation (Page1G-

9)”.

2) Check for the following points and replace if any

abnormal condition is found.

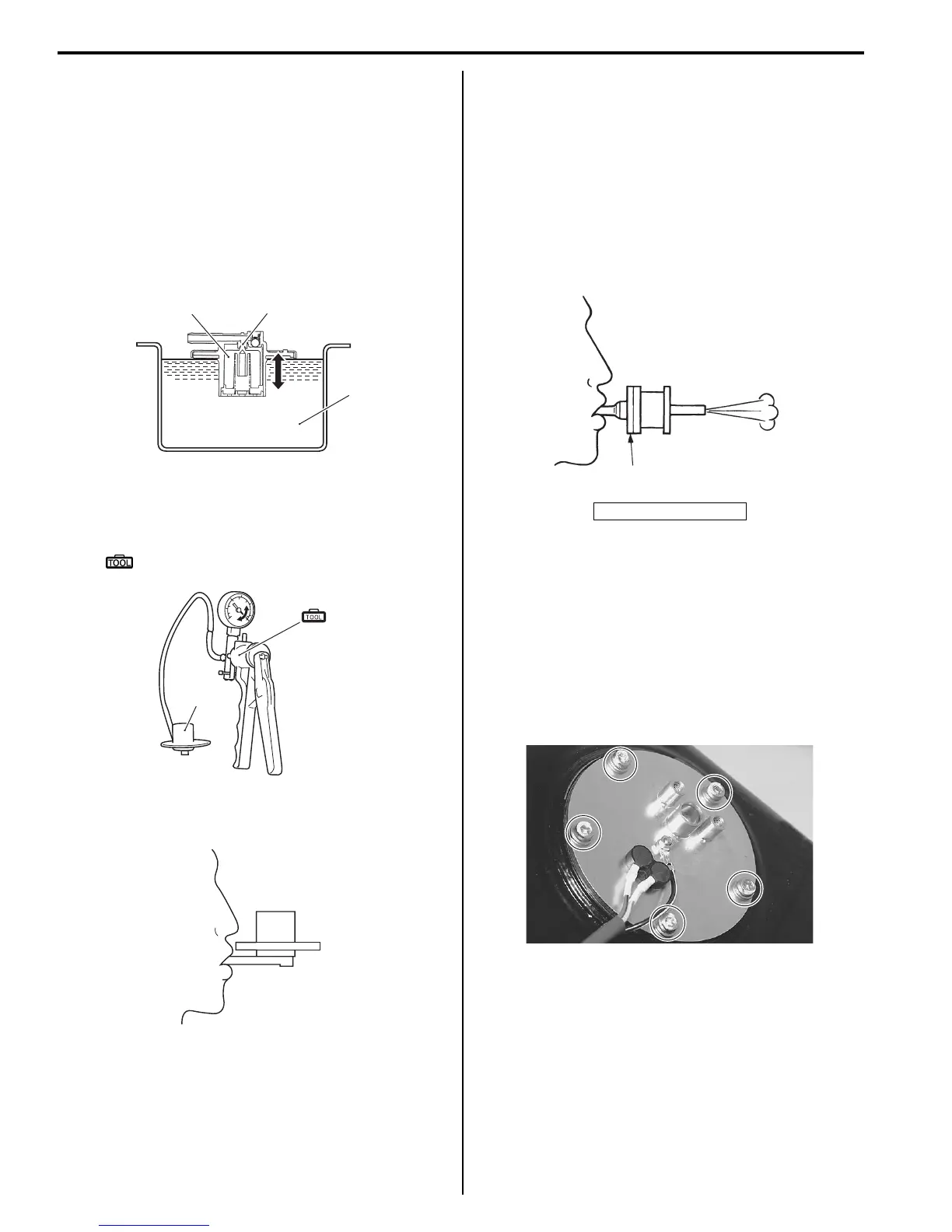

• With the fuel cut valve being immersed in

kerosene (1), check that valve (2) operates

smoothly and valve seat (3) contacts correctly.

• Using the special tool, apply vacuum to the fuel

cut valve (4) and check that the gauge pointer

moves correctly.

Special tool

(A): 09917–47011 (Vacuum pump gauge)

• Check for resistance when the fuel cut valve is

blown.

3) After finishing the fuel cut valve inspection, reinstall

the fuel cut valve. Refer to “Fuel Drain Tray and

FTPC Valve Removal and Installation (Page1G-9)”.

FTPC Valve Inspection

B705H11706023

Inspect the FTPC valve in the following procedures:

1) Remove the FTPC valve. Refer to “Fuel Drain Tray

and FTPC Valve Removal and Installation (Page1G-

9)”.

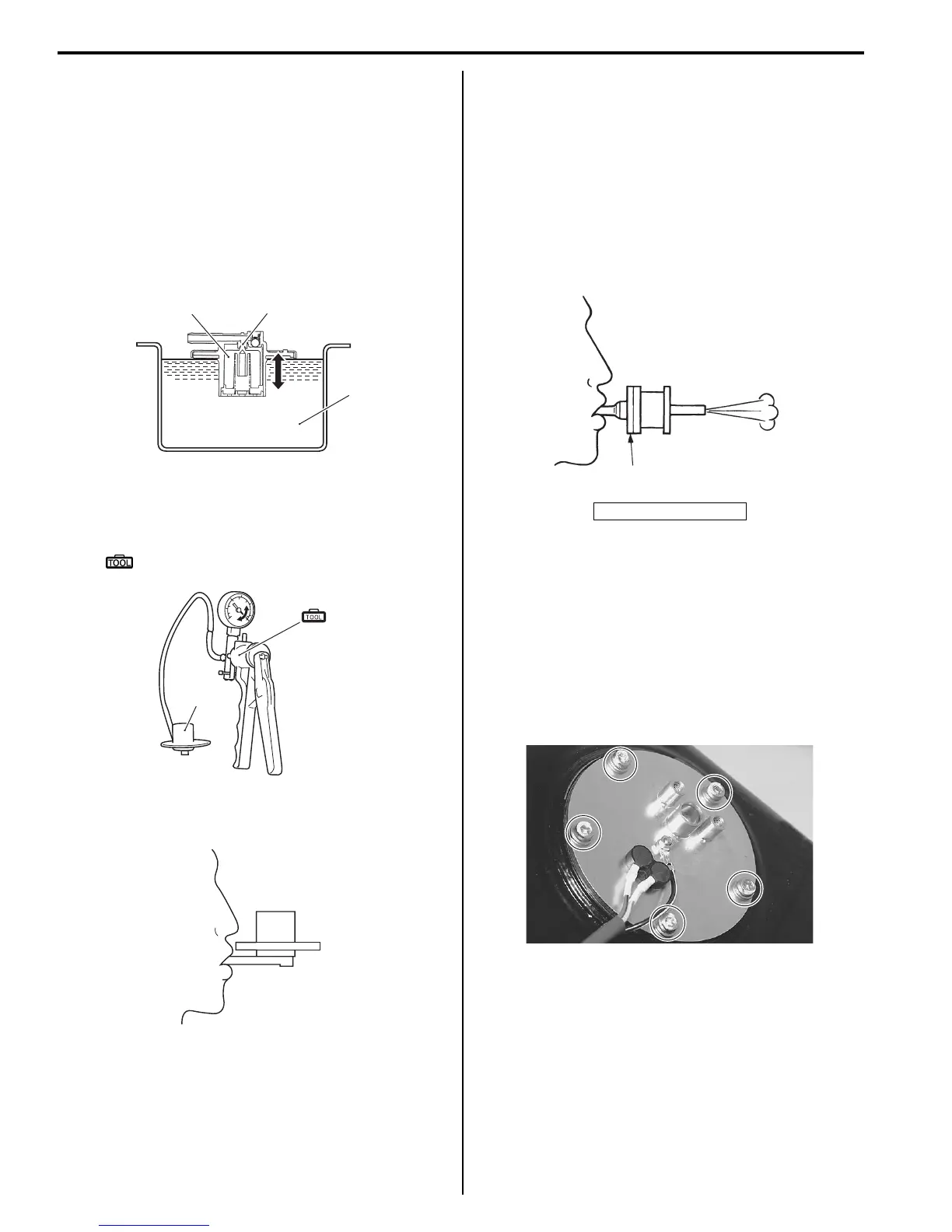

2) Check that air passes easily when blown from the

orange paint side of the FTPC valve and that

resistance exists when blown from the other side. If

any abnormal condition exists, replace the valve with

a new one.

3) After finishing the FTPC valve inspection, reinstall

the FTPC valve. Refer to “Fuel Drain Tray and FTPC

Valve Removal and Installation (Page1G-9)”.

Fuel Pump Disassembly and Assembly

B705H11706011

Disassembly

1) Remove the fuel pump assembly.

Refer to “Fuel Pump Assembly Removal and

Installation (Page1G-8)”.

1

3

2

I705H1170011-01

(A)

4

I705H1170012-01

I705H1170013-01

“A”: Orange

“A”

I705H1170014-02

I705H1170015-01

Loading...

Loading...